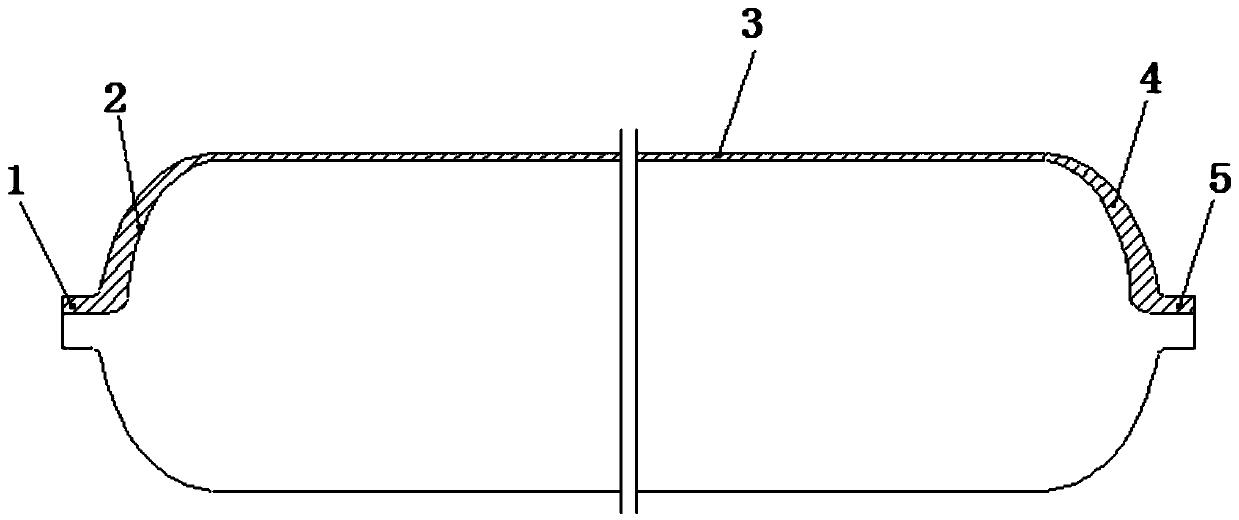

Double-end-seal ultra-large-size ultrahigh-pressure gas cylinder liner and manufacturing method thereof

A technology of super large size and manufacturing method, applied in the direction of container filling method, container structure manufacturing, container discharge method, etc., can solve the problems of heavy weight, small volume of ultra-high pressure gas cylinder, poor reliability, etc., and achieve high processing accuracy, Strict effect of surface quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

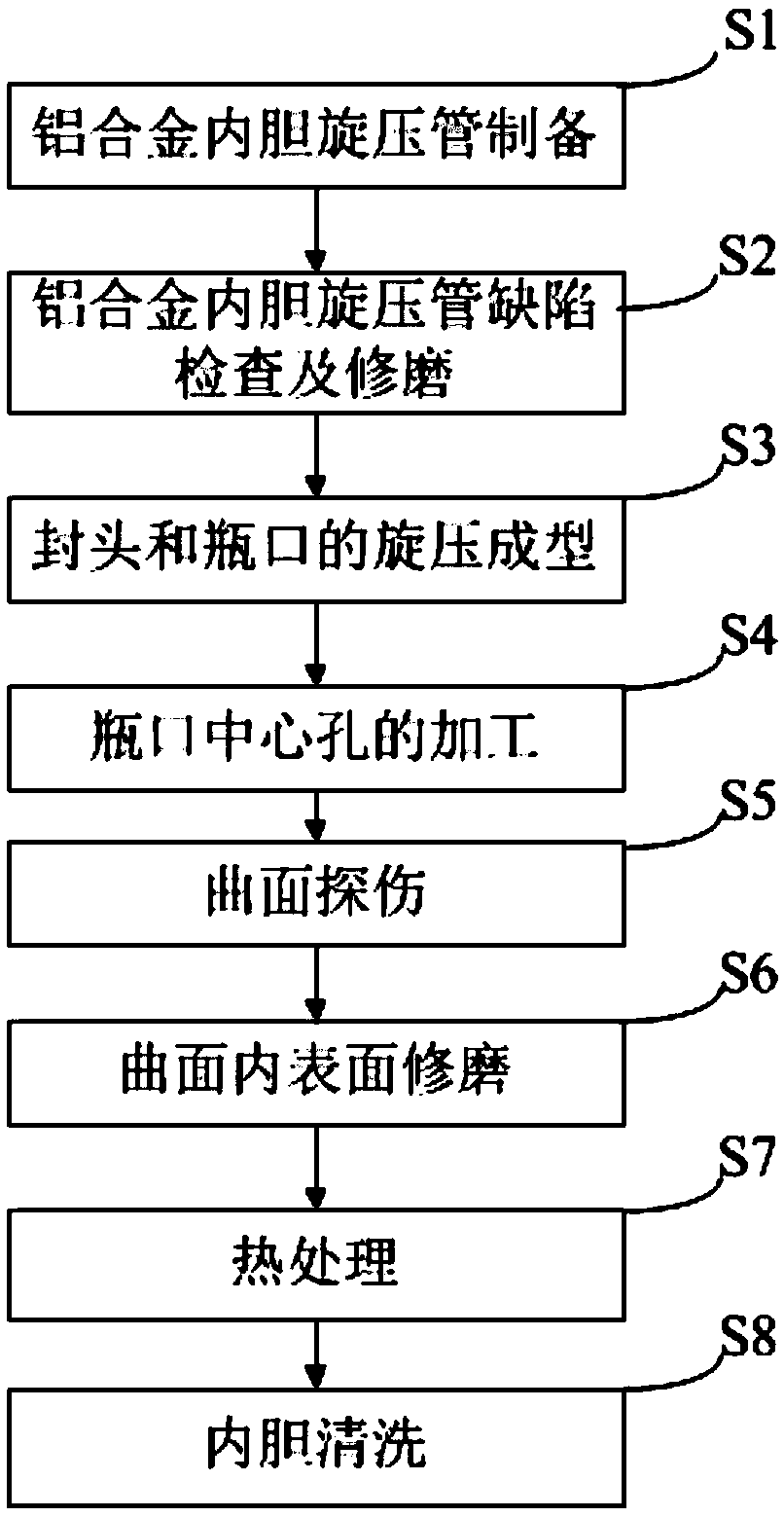

[0117] Prepare a double-head ultra-large ultra-high-pressure gas cylinder liner with a diameter of 779mm, a length of 12m, and a wall thickness of 8mm. The rated pressure of the ultra-high-pressure gas cylinder is required to be 50Mpa, specifically including the following steps:

[0118] S1, the preparation of aluminum alloy liner spinning tube, this step specifically includes the following steps:

[0119] S1a, the spinning forming of the straight section 3 of the aluminum alloy liner spinning tube, the seamless tube with a length of 1.6m is used for 4 times of spinning by the tension three-wheel staggered forward spinning method, and the spinning process is 2m The long floating mandrel is assisted by spinning; the stagger amount in the tension three-wheel staggered forward spinning method is set to 6mm; thus the spinning part A is obtained. The spinning part A is a straight tube of equal thickness or a straight tube section 3 with outer circumferential end frames at both ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com