Variable cycle high bypass ratio turbofan engine

A turbofan engine, high bypass ratio technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of limited engine life, high combustion chamber outlet temperature, limited thrust margin development, etc. The effect of avoiding energy loss, increasing service life and reducing total temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

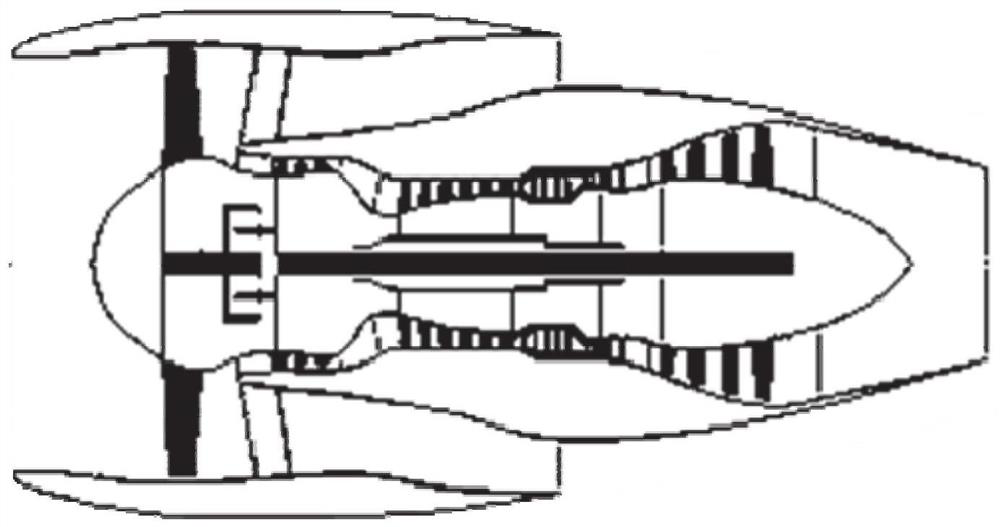

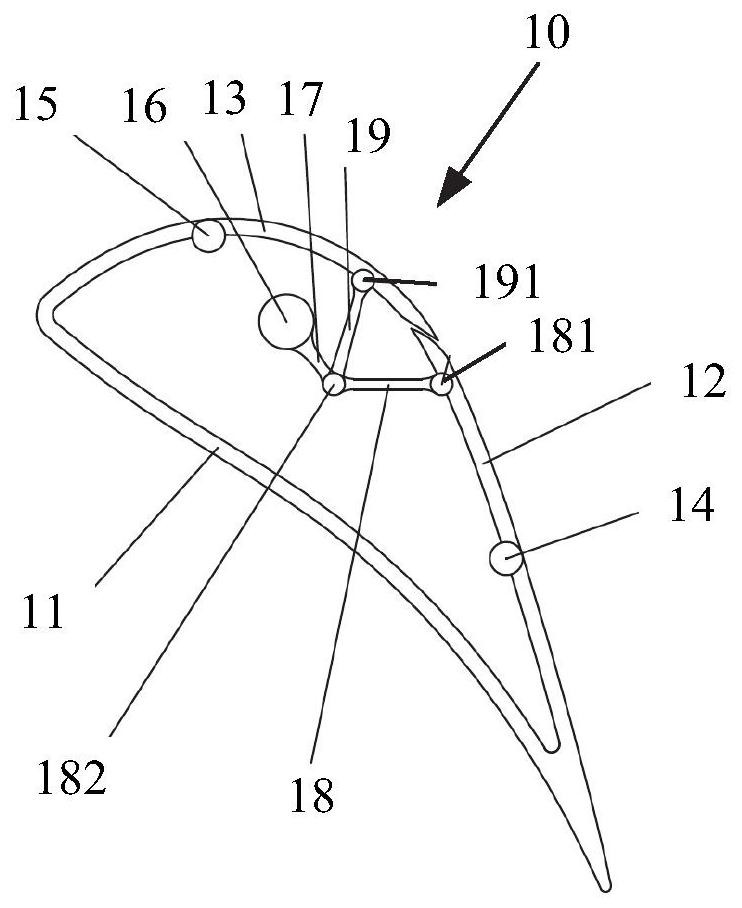

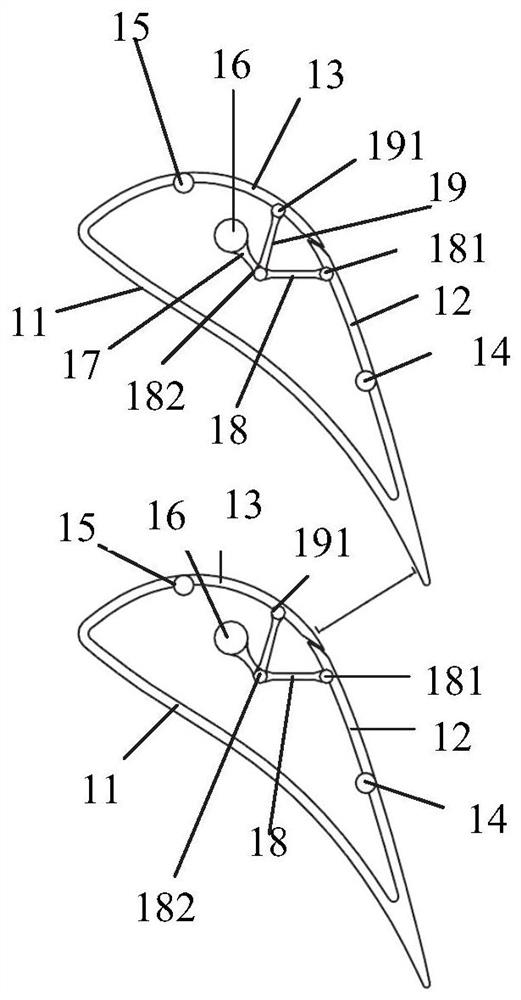

[0046] figure 1It is a structural schematic diagram of a dual-shaft direct-drive turbofan engine with a large bypass ratio in the prior art. figure 2 It is a structural schematic diagram of Embodiment 1 of the turbine guide vane in the variable cycle high bypass ratio turbofan engine of the present invention. image 3 It is a schematic diagram of the arrangement state of Embodiment 1 of the turbine guide vanes in the variable cycle large bypass ratio turbofan engine of the present invention Figure 1 . Figure 4 It is a schematic diagram of the arrangement state of Embodiment 1 of the turbine guide vanes in the variable cycle large bypass ratio turbofan engine of the present invention Figure II .

[0047] Such as Figure 1 to Figure 4 As shown, the variable cycle high bypass ratio turbofan engine of the present invention includes a plurality of turbine guide vanes 10, which include a blade portion 11 of a fixed structure, and a plurality of movable blade segments connect...

Embodiment 2

[0055] Figure 5 It is a structural schematic diagram of the second embodiment of the turbine guide vane in the variable cycle high bypass ratio turbofan engine of the present invention. Image 6 It is a schematic diagram of the arrangement state of the second embodiment of the turbine guide vanes in the variable cycle large bypass ratio turbofan engine of the present invention Figure 1 . Figure 7 It is a schematic diagram of the arrangement state of the second embodiment of the turbine guide vanes in the variable cycle large bypass ratio turbofan engine of the present invention Figure II .

[0056] Such as Figure 5 to Figure 7 As shown, the variable cycle high bypass ratio turbofan engine of the present invention includes a plurality of turbine guide vanes 20, which include a blade portion 21 of a fixed structure, and a plurality of movable blade segments connected by hinges , and form a hollow area with the blade part 21 of the fixed structure, and the throat area be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com