Cable anchoring anti-corrosion structure of stayed-cable bridge and anti-corrosion technology

A technology for cable-stayed bridges and cable anchors, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of reducing the service life of cable-stayed bridges, easily seeping water into the connecting tube, and not tight sealing, etc., and achieves convenient construction Fast, remarkable waterproof effect, long-term effective effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific embodiments.

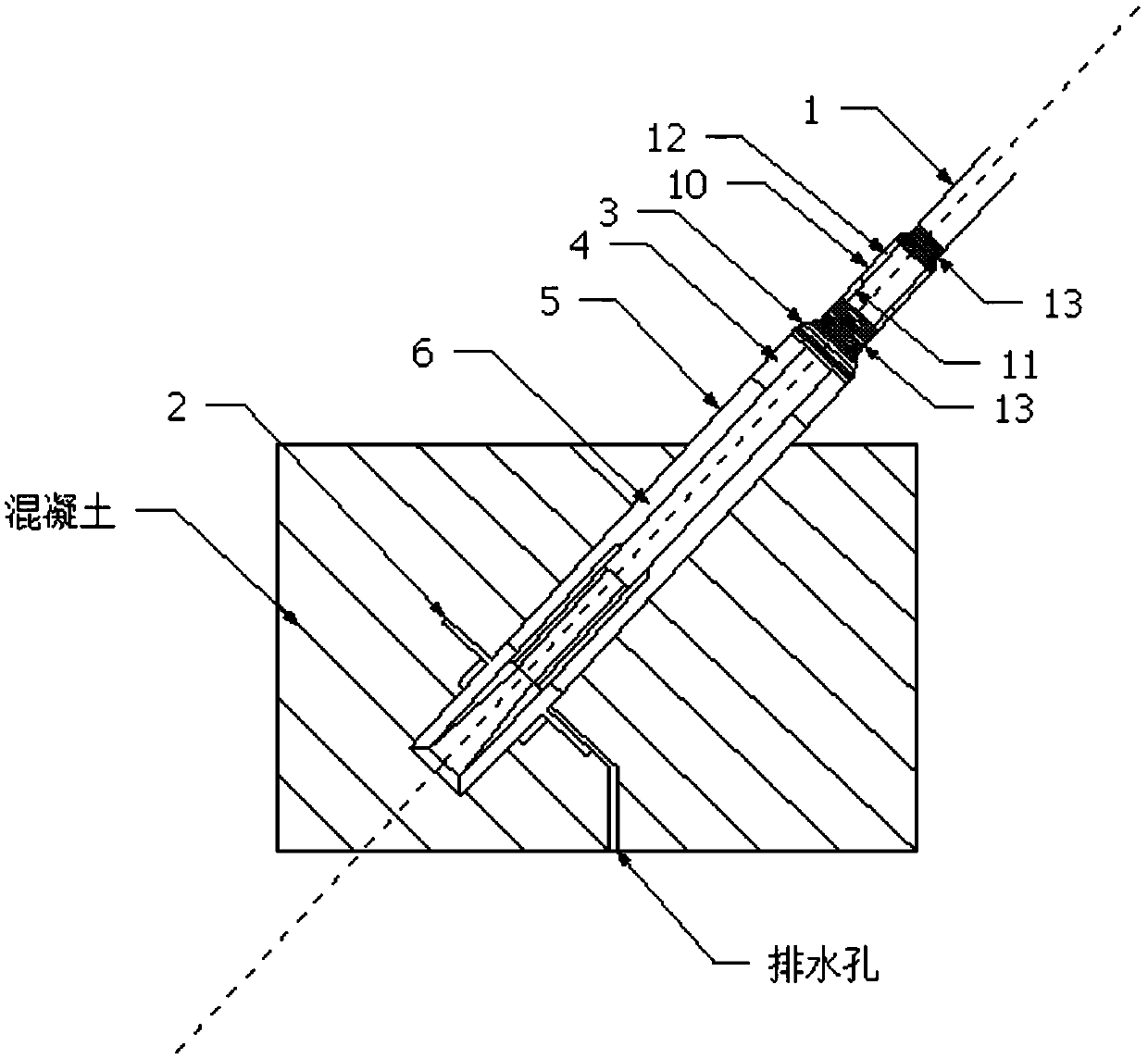

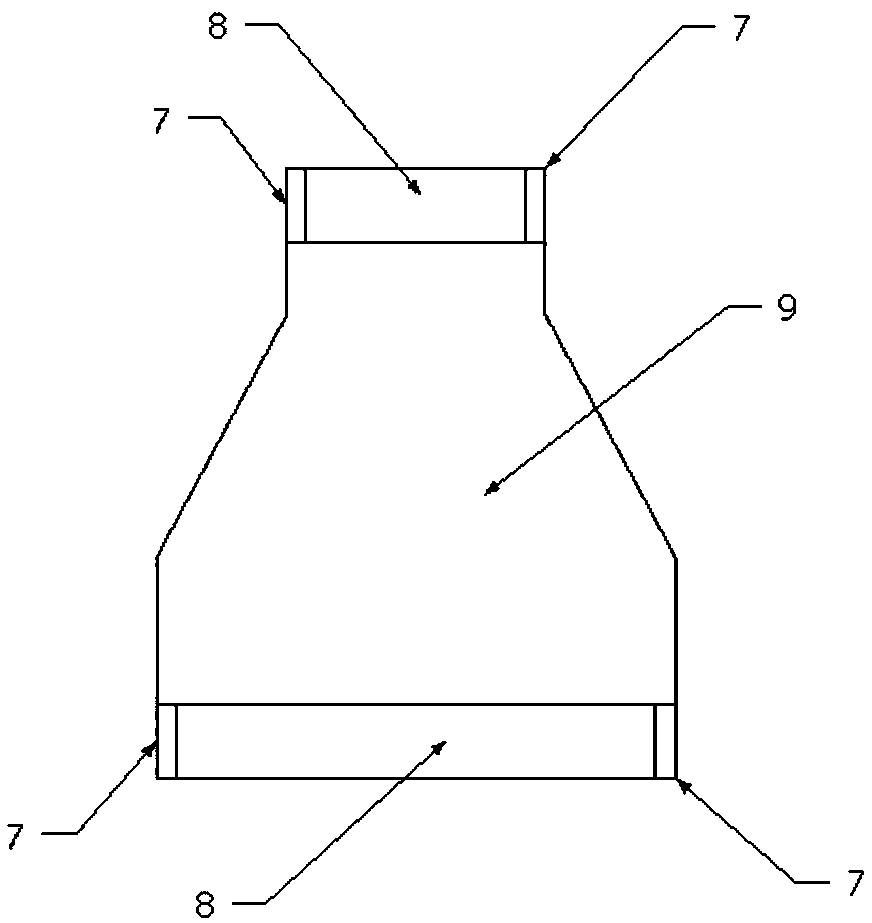

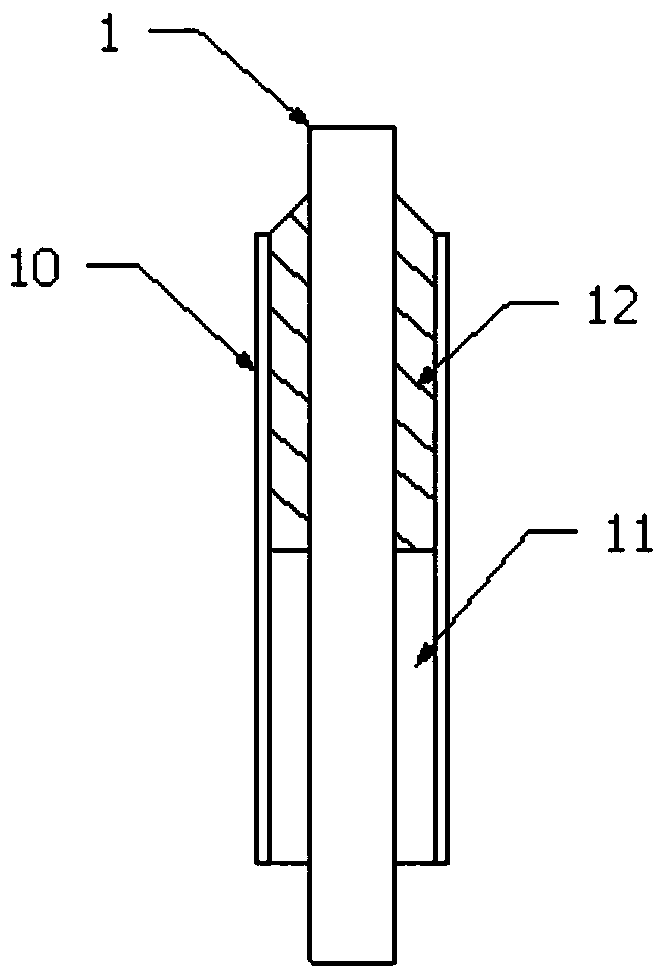

[0026] like Figure 1-3 As shown, a cable-stayed cable anchorage anti-corrosion structure of the present invention includes a cable 1, and one end of the cable 1 is anchored in the concrete through the lower anchor head 2; it also includes a pre-embedded pipe 5 embedded in the concrete at one end , the embedded tube 5 is set on the cable 1; the other end of the embedded tube 5 is provided with a waterproof cover 3, and the waterproof cover 3 is connected to the protective tube 10 set on the cable 1; the waterproof cover 3 is set on the outside of the cable 1, waterproof The inside of the cover 3 is filled with foam material 9; rubber rings 7 are set on the inside of both ends of the waterproof cover 3, and filled with silica gel 8. The gap, the protective tube 10 is filled with sealing materials, the sealing materials are polysulfide anti-corrosion sealant 11 and non-sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com