Multi-principal-component medium-entropy alloy and preparation method thereof

An entropy alloy and multi-principal technology, which is applied to the multi-principal entropy alloy and its preparation field, can solve the problems of complex smelting process and high cost, and achieve the effects of simplified process, low cost and favorable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

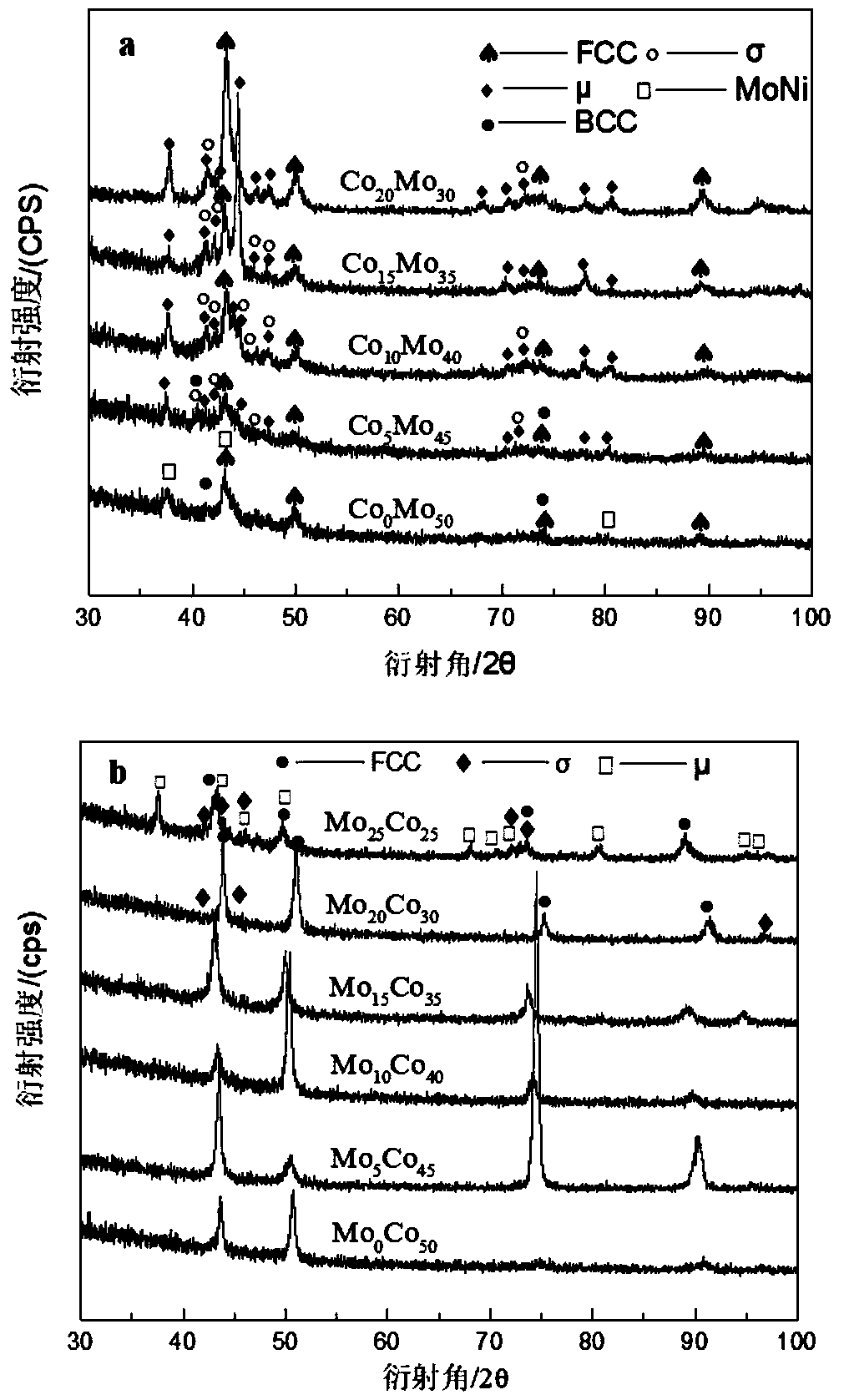

[0028] 1. Fe of the present invention 25 Ni 25 co 50-x Mo x The preparation process of medium entropy alloy is as follows:

[0029] Step 1: Precisely calculate and weigh the high-purity metal raw material (≥99.95%) according to the mass percentage, for use in smelting alloys;

[0030] Step 2: Using WK type non-consumable vacuum electric arc furnace, put the weighed elemental raw materials into the water-cooled copper mold melting pool in the vacuum electric arc furnace, place oxygen-absorbing titanium in the middle of the crucible, then close the furnace door, and tighten the knob;

[0031] Step 3: Vacuum the electric arc furnace, when the vacuum degree reaches 5×10 -3 After Pa, fill the furnace with argon gas with a purity of 99.99wt% to normal pressure, so as to prevent the alloy from being oxidized and reduce volatilization during alloy melting. In this way, "vacuumize-fill with argon" three times can be smelted. Melting at 400A current for about 30 seconds, turning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com