Phage flocculant and application of phage flocculant in fermentation post-treatment technology

A processing technology and phage technology, applied in the direction of phage, virus/phage, microorganism, etc., can solve the problem of high power consumption cost of centrifuges and centrifugal aids, and achieve the effect of meeting the requirements of industrialized mass production, simple preparation process and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Flocculant sedimentation to obtain Vibrio parahaemolyticus phage process: Add 3% working concentration of polyferric aluminum chloride flocculant to the obtained mixed fermentation broth of Vibrio parahaemolyticus phage and Vibrio parahaemolyticus, manually or using a mixer (During mass production) Stir evenly, stand at room temperature for 3 hours, take the supernatant when upper and lower stratification occurs, and pass the supernatant through a 0.2 micron bacterial filter membrane to obtain a finished filtrate.

[0042] Centrifuge separation process to obtain Vibrio parahaemolyticus phage: centrifuge the obtained Vibrio parahaemolyticus phage and Vibrio parahaemolyticus mixed fermentation broth at 6000 rpm for 10 min, separate Vibrio parahaemolyticus and supernatant through a centrifuge, Take the supernatant and pass it through a 0.2 micron bacterial filter to obtain the finished filtrate.

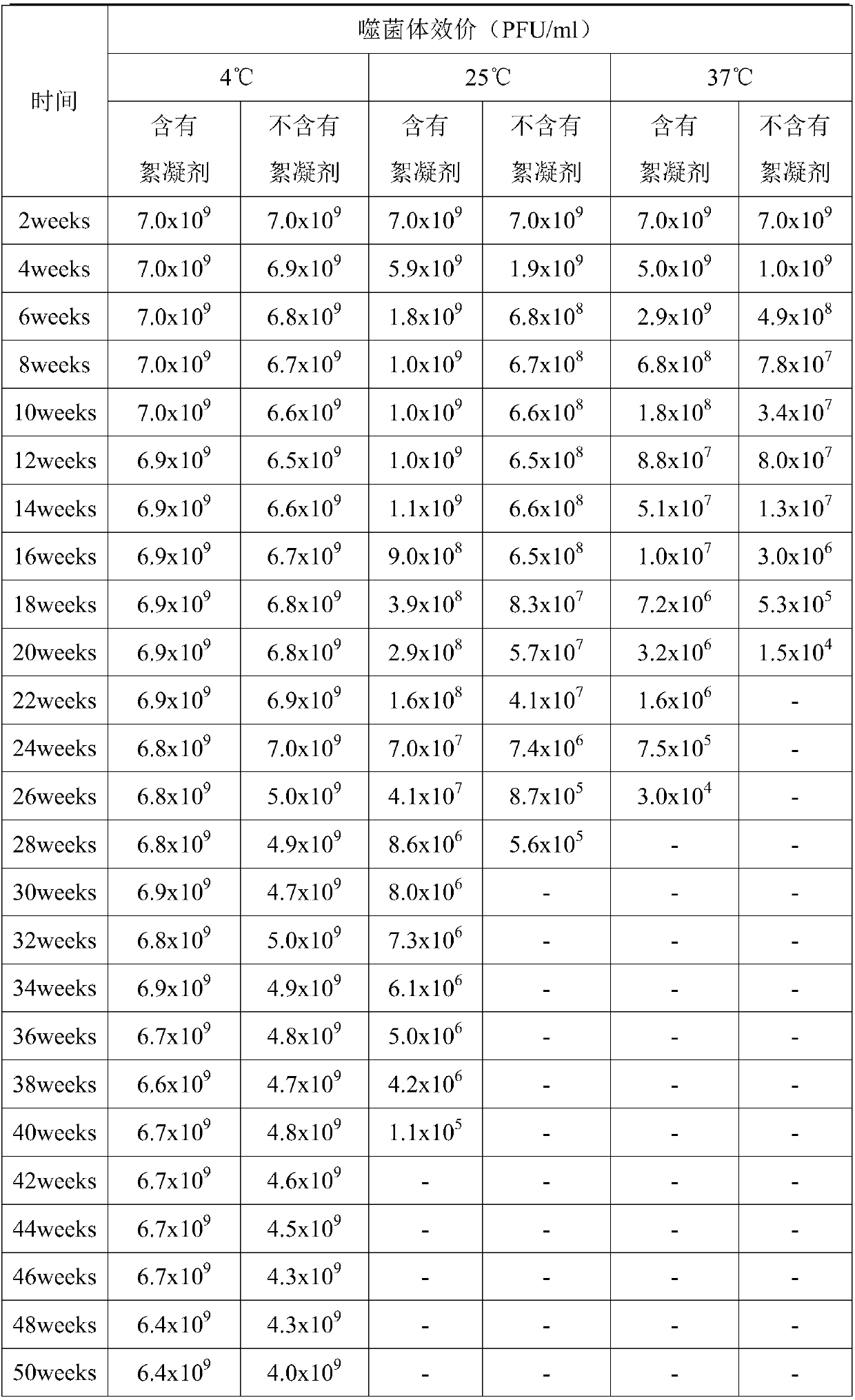

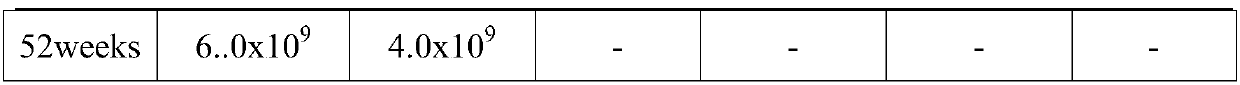

[0043] Vibrio parahaemolyticus phage VP46, Vibrio parahaemolyticus phage VP4...

Embodiment 2

[0053] Flocculant sedimentation to obtain Xanthomonas rugosa phage process: Add 0.1% polysilicate flocculant at working concentration to the obtained mixed fermentation broth of Xanthomonas rugosa bacteriophage and Xanthomonas rugosa, manually or using a mixer (During mass production) Stir evenly, stand at room temperature for 3 hours, take the supernatant when upper and lower stratification occurs, and pass the supernatant through a 0.2 micron bacterial filter membrane to obtain a finished filtrate.

[0054] Centrifuge separation process to obtain Xanthomonas rugosa bacteriophage: Centrifuge the obtained Xanthomonas rugosa bacteriophage and Xanthomonas rugosa mixed fermentation broth at 6000 rpm for 10 minutes, pass Xanthomonas rugrugosa and supernatant through The centrifuge separates, and the supernatant is passed through a 0.2-micron bacterial filter to obtain a finished filtrate.

[0055] Get three groups of 500 ml of Xanthomonas rugosa phage preparations obtained in two ...

Embodiment 3

[0065] The process of obtaining Salmonella phage by flocculant sedimentation: Add 5% working concentration of polyphosphorus aluminum flocculant to the obtained Salmonella phage and Salmonella mixed fermentation broth, stir it manually or with a mixer (in mass production), and let it stand at room temperature for 3 hours. Take the supernatant during stratification, and pass the supernatant through a 0.2 micron bacterial filter to obtain the finished filtrate.

[0066] Centrifuge separation to obtain Salmonella phage process: centrifuge the obtained Salmonella phage and Salmonella mixed fermentation broth at 6000 rpm for 10 minutes, separate Salmonella and supernatant through a centrifuge, and take the supernatant to pass through a 0.2 micron bacterial filter membrane to obtain the finished filtrate.

[0067] Get three groups of 500 ml of Salmonella phage preparations obtained in two ways and let stand. The control examples containing flocculant and no flocculant were combined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Potency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com