Clamping device used for internal gear machining

A clamping device and internal gear technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of loose clamping, sticking, and excessive waste, and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

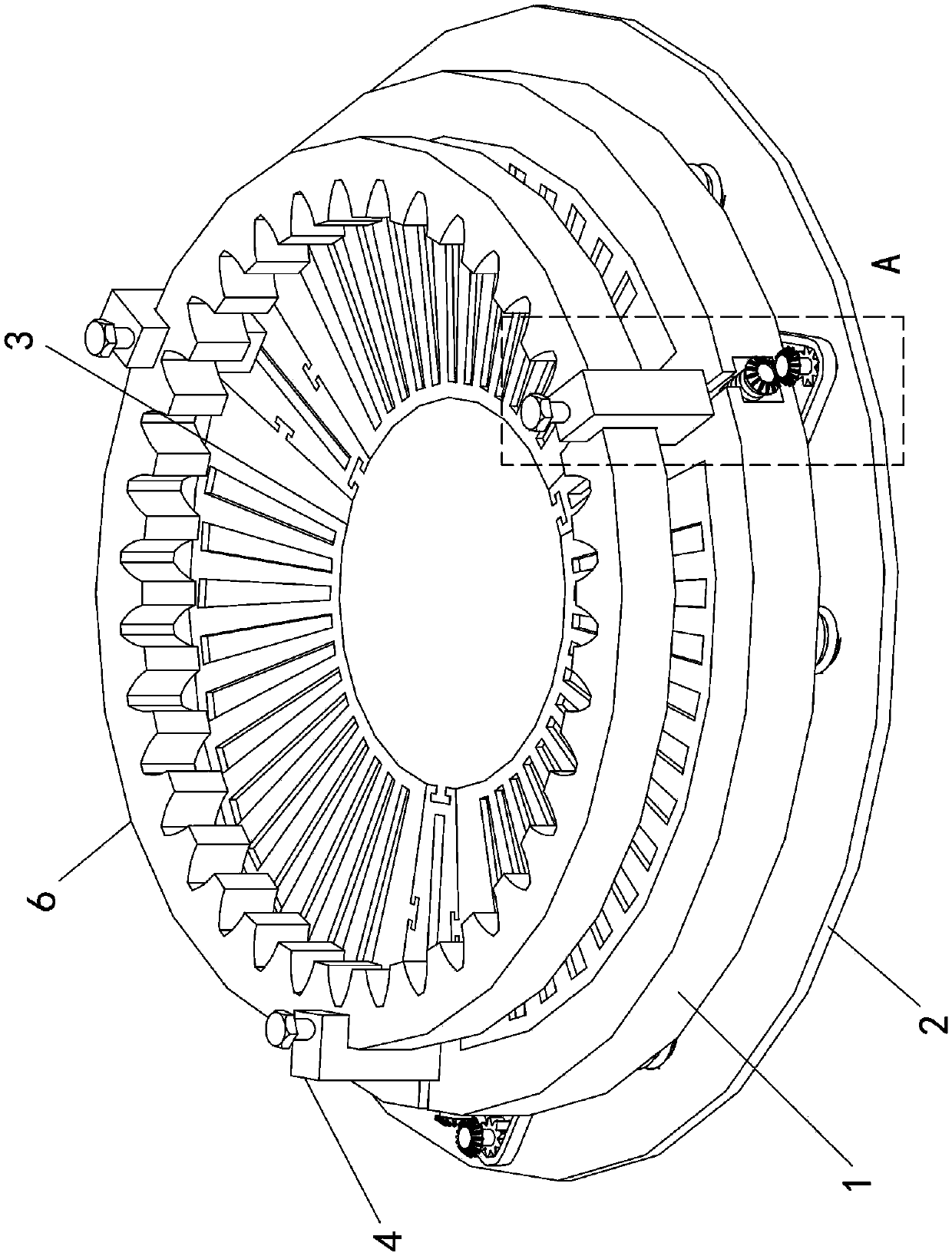

[0017] Specific implementation mode one: as Figure 1 to Figure 6 As shown, the present invention discloses a clamping device for processing internal gears, including a base 1, a base 2, a dust collector 3, three sets of clamping mechanisms 4 and a plurality of support columns 5;

[0018] The base 1 is a cylinder, and the three sets of clamping mechanisms 4 are equally divided along the circumferential direction of the base 1, and each set of clamping mechanisms 4 is horizontally slidably connected with the base 1. Three sets of clamping mechanisms 4 are used to fix the internal gear 6 to be processed. The end surface of the base 1 is provided with a through groove 1-1, and the inner side wall of the through groove 1-1 is vertically slidably connected with The dust suction device 3 is fixedly connected between the base 1 and the base 2 through a plurality of support columns 5 .

specific Embodiment approach 2

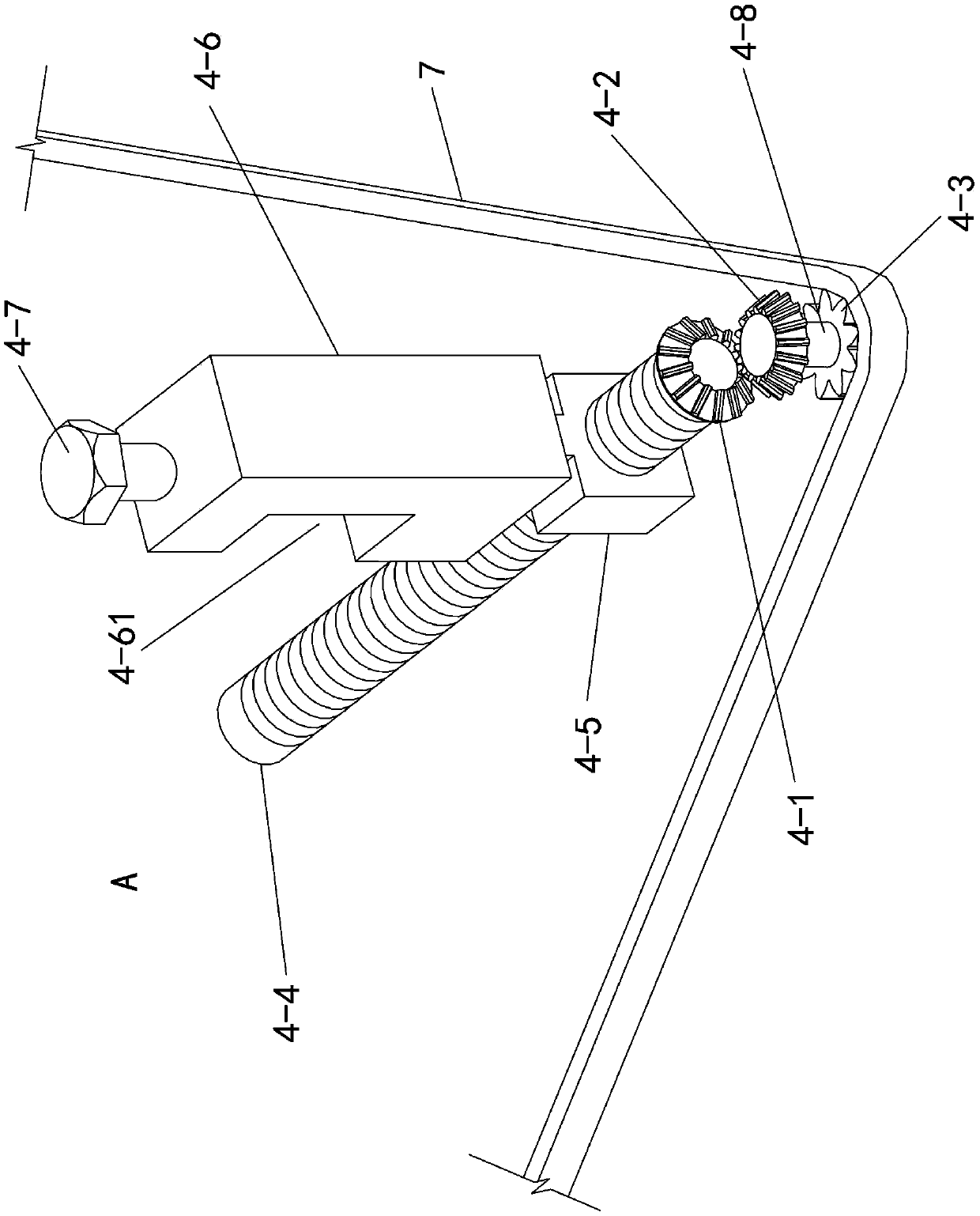

[0019] Specific implementation mode two: as Figure 2 ~ Figure 4 As shown, this embodiment is a further description of the first embodiment, the clamping device for internal gear processing also includes a chain 7 and a motor 8;

[0020] The clamping mechanism 4 described in each group all comprises bevel gear one 4-1, bevel gear two 4-2, sprocket wheel 4-3, threaded rod 4-4, slide block one 4-5, gear clamping block 4-6 , compression nut 4-7 and shaft rod 4-8;

[0021] The upper end surface of the base 1 is provided with three horizontal chute 1-2 equally divided along the circumferential direction, each of the horizontal chute 1-2 is slidably connected with a slider 4-5, each The upper ends of each of the first sliders 4-5 are fixed with gear clips 4-6, and the side walls of each of the gear clips 4-6 are provided with notches 4-61, and the three described three A notch 4-61 is used to place the internal gear 6 to be processed, and the upper end surface of each of the gear ...

specific Embodiment approach 3

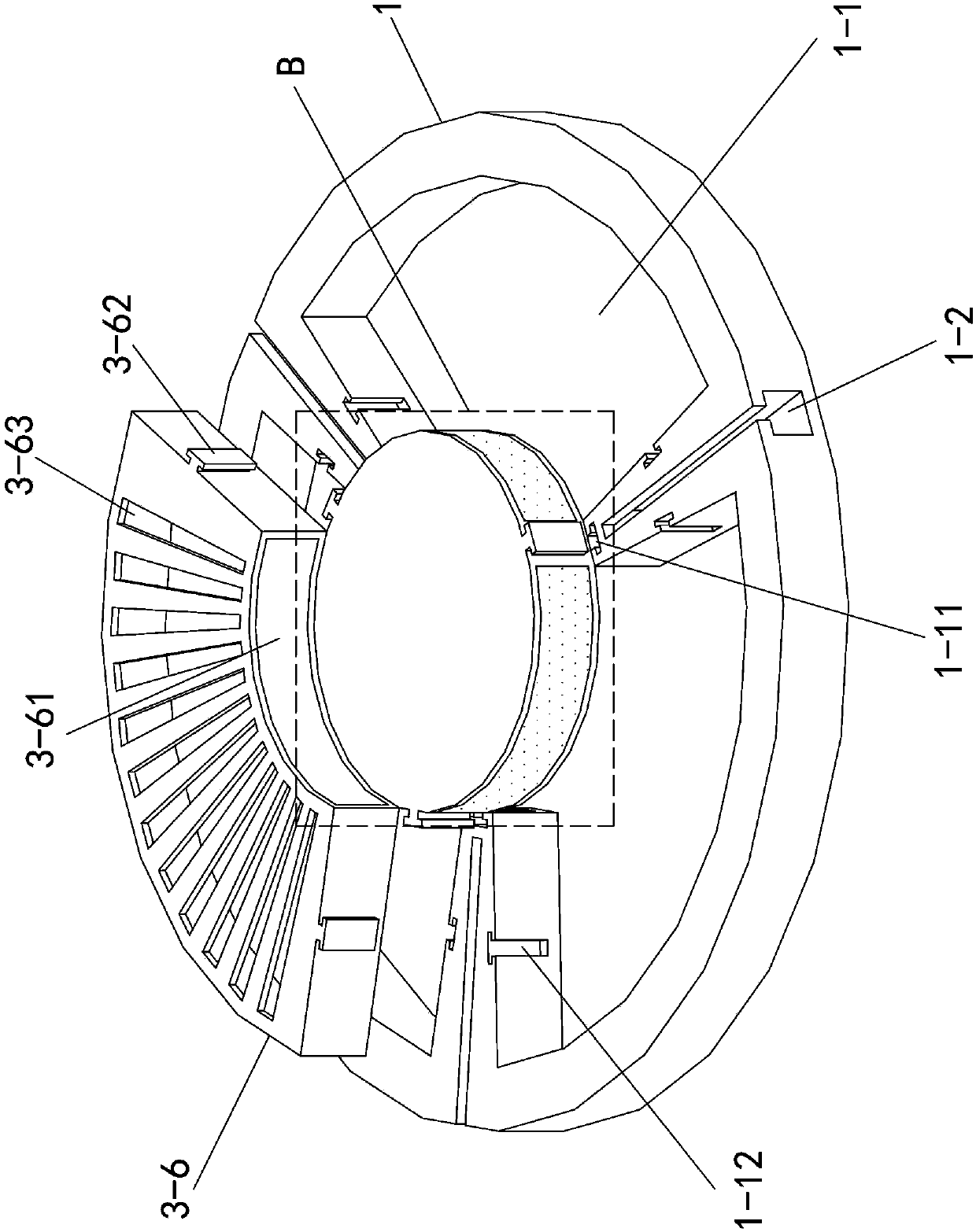

[0022] Specific implementation mode three: as image 3 , Figure 5 , Image 6 As shown, this embodiment is a further description of Embodiment 1. The dust collection device 3 includes a cylindrical box 3-1, a fan blade 3-2, a rotating shaft 3-3, an electric motor 3-4, and three A dust filter 3-5 and three dust collecting boxes 3-6;

[0023] Described rotating shaft one 3-3 is arranged in the cylindrical case 3-1, and the upper end of described rotating shaft one 3-3 is connected with the top plate of cylindrical case 3-1 by bearing three rotations, and the described rotating shaft one 3-3 The lower end is fixed with an electric motor 3-4, and the electric motor 3-4 is fixed on the bottom plate of the cylindrical box 3-1, and the outer side of the rotating shaft 3-3 is fixed with a fan blade 3-2, and the The cylindrical box 3-1 is slidingly connected with the inner side wall of the through groove 1-1 on the base 1, and the outer side wall of the cylindrical box 3-1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com