Nozzle air pressure adjusting device with improved sealing performance

A technology of air pressure adjustment and sealing performance, which is applied in the field of additive manufacturing to achieve the effect of reasonable design, simple structure and improved spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

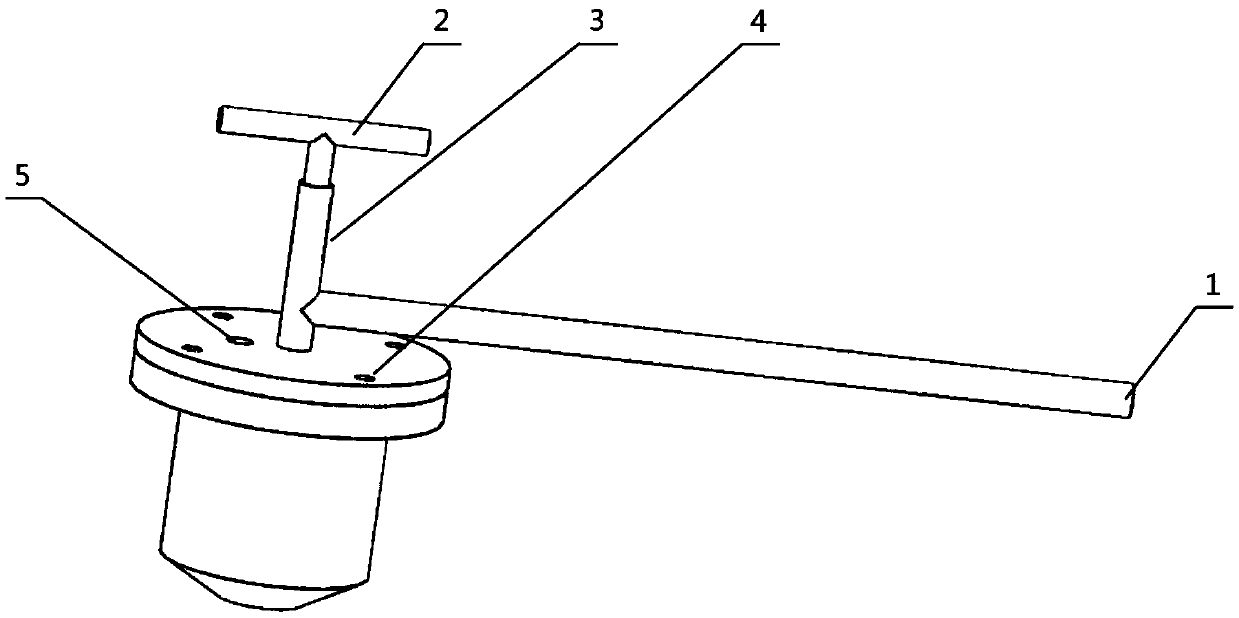

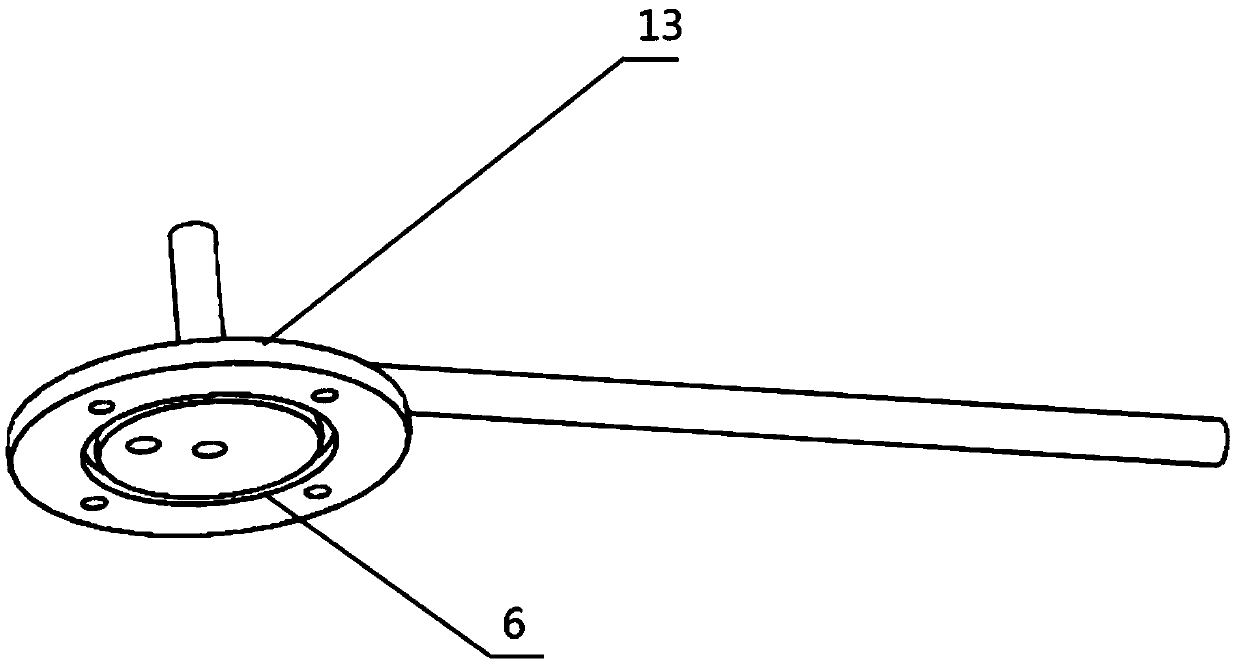

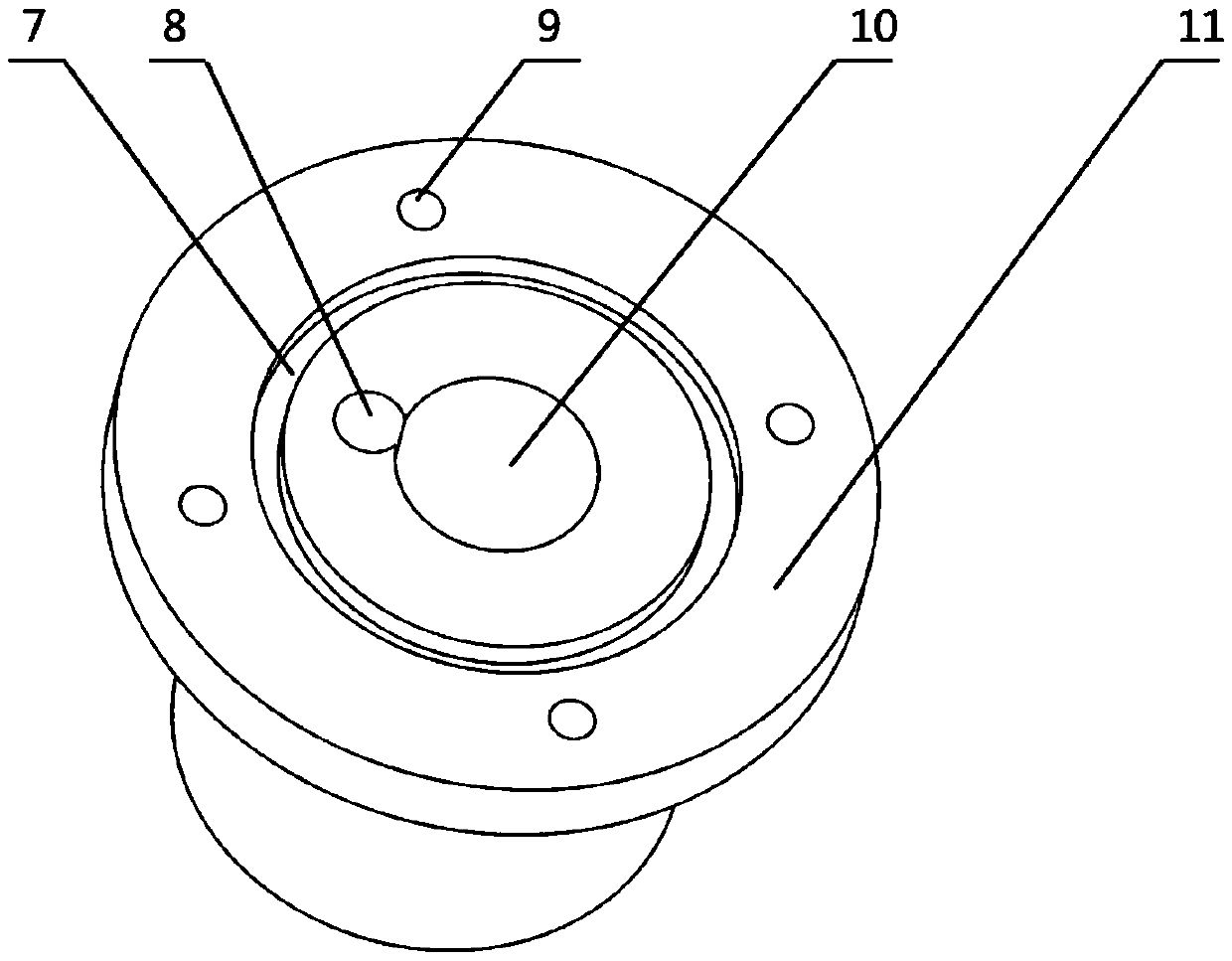

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] a) Due to the need to ensure the stability of the air pressure inside the cavity, there is a high requirement on the sealing performance, and at the same time, it must be able to work under high temperature conditions, so the method of bolt fastening and sealant is used for sealing.

[0025] b) In order to reduce the energy dissipation during the working process of the pneumatic nozzle and ensure the stability of the air pressure acting on the molten metal surface, the cone angle of the processed nozzle (7) should be less than 90°, and the aspect ratio should be 1.

[0026] c) In order to ensure the service life of the pneumatic nozzle (5) and the nozzle (7), the materials are made of high temperature resistant stainless steel and graphite crucible.

[0027] d) In order to improve the injection effect of the pneumatic nozzle (5), the cavity vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com