Process method of stamping forming of saw arm of swing saw

A stamping forming and process method technology, applied in the field of stamping process, can solve the problems of difficulty in improving the production efficiency of the swing saw saw arm, affecting the product quality, uneven force on the material plate, etc., so as to improve the forming quality, save the steps, reduce the Effects of Punch Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

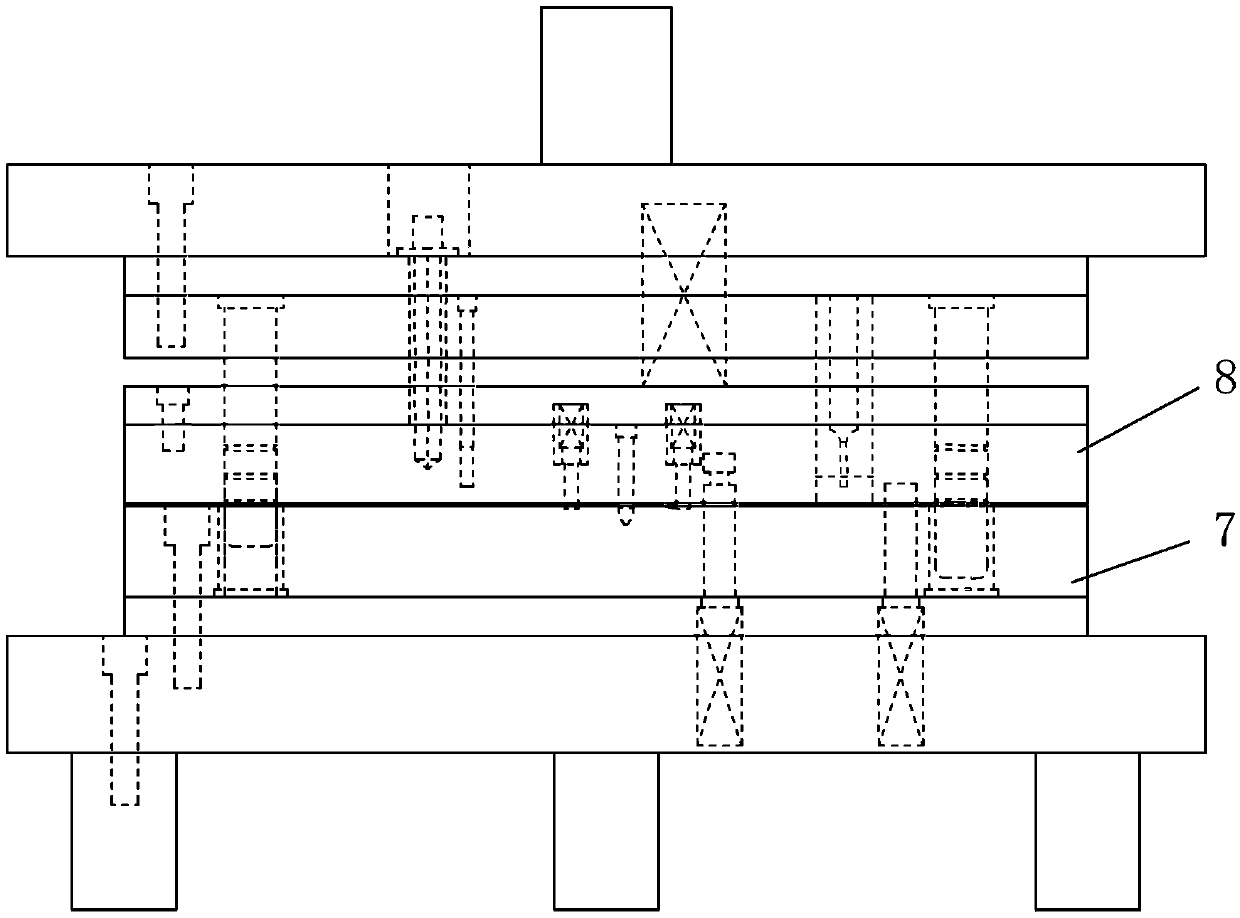

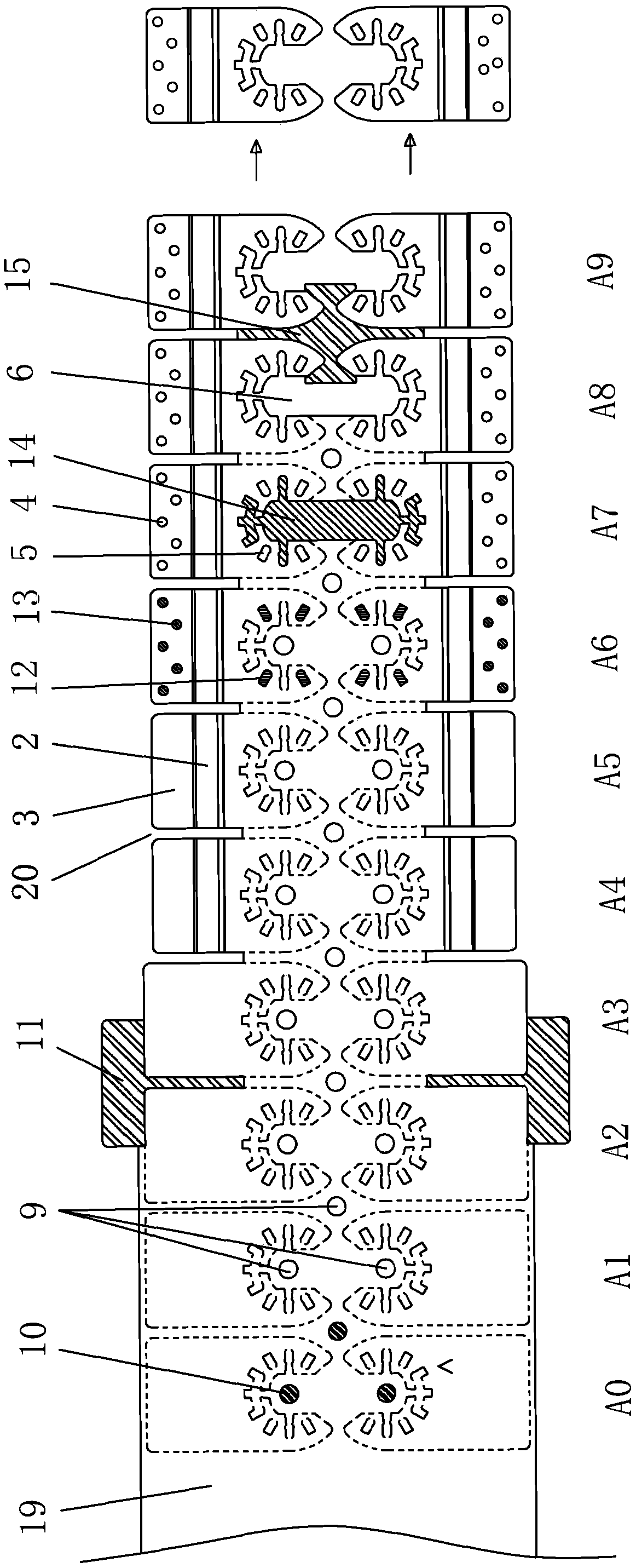

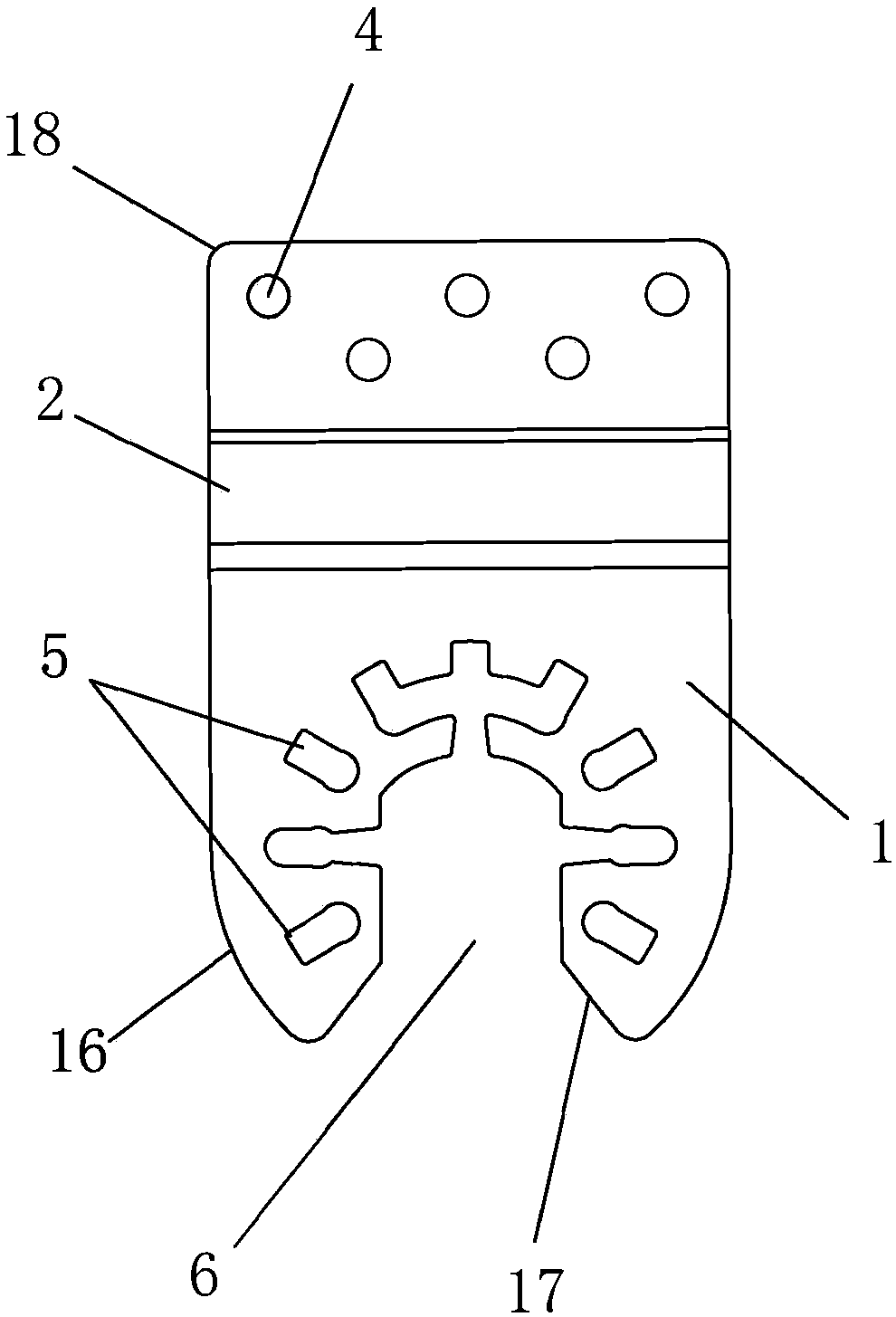

[0026] Embodiment: The present invention a kind of technology method of stamping and forming of saw arm of swing saw, its forming process, as attached figure 2 shown; the mold used, as attached figure 1 shown. The specific method is:

[0027] On the stamping position, the punched two swing saw arms are arranged symmetrically up and down, and the mouths of the middle holes 6 of the two swing saw arms face each other; A0 pre-carry and A1-A9 nine progressive positions are arranged in sequence in the mold cavity ,in:

[0028] 1) A0 pre-carry punching guide hole 9;

[0029] 2) An edge trimming punch 11 is set up and down between the A2 and A3 grades to cut off the side edge of the material plate 19 and form the top edge of the substrate 1, wherein the A2 grade punching cuts off the right part (here the right The side part refers to the right side of the two-piece oscillating saw arm at the level of progress, not the right side of the finished product of the single-piece oscil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com