Preparation method of laser-synthesized oxygen-vacancy tunable cobalt tetraoxide nitrogen-doped graphene

A technology of cobalt nitrogen oxide and laser synthesis, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of ineffective regulation and control of content, and achieve improved catalytic performance, easy control, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

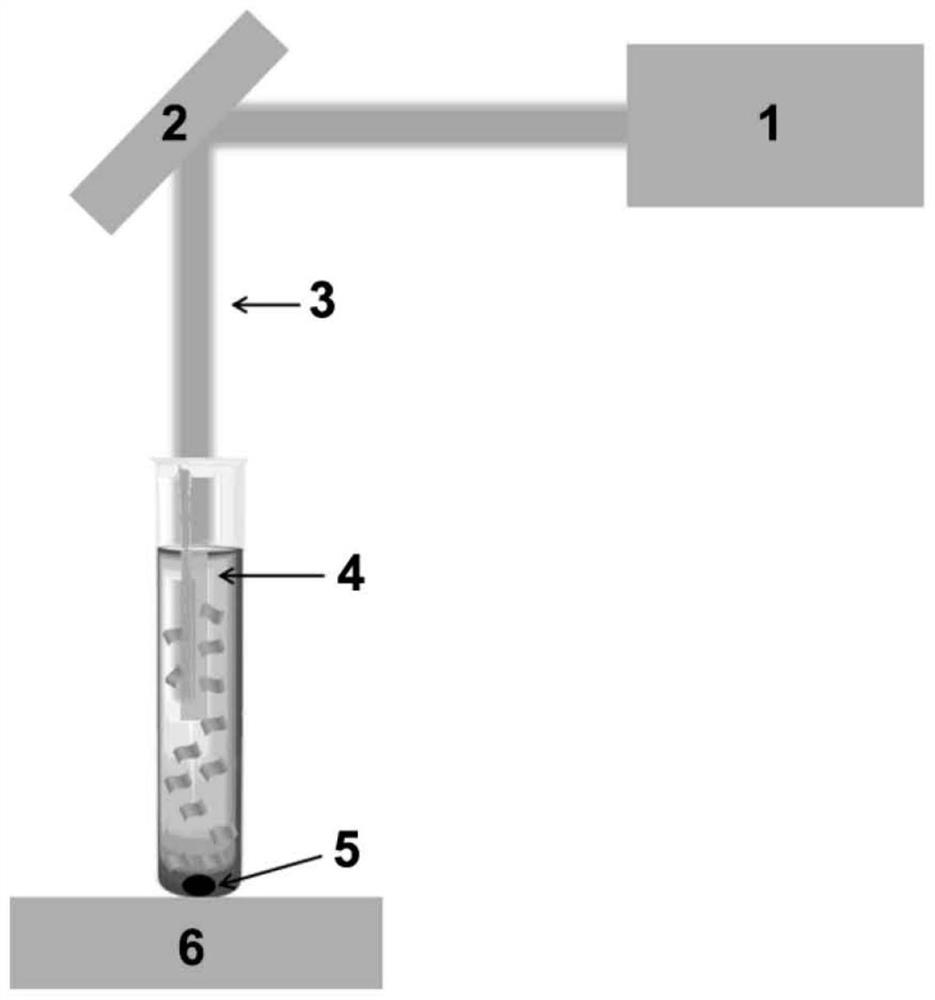

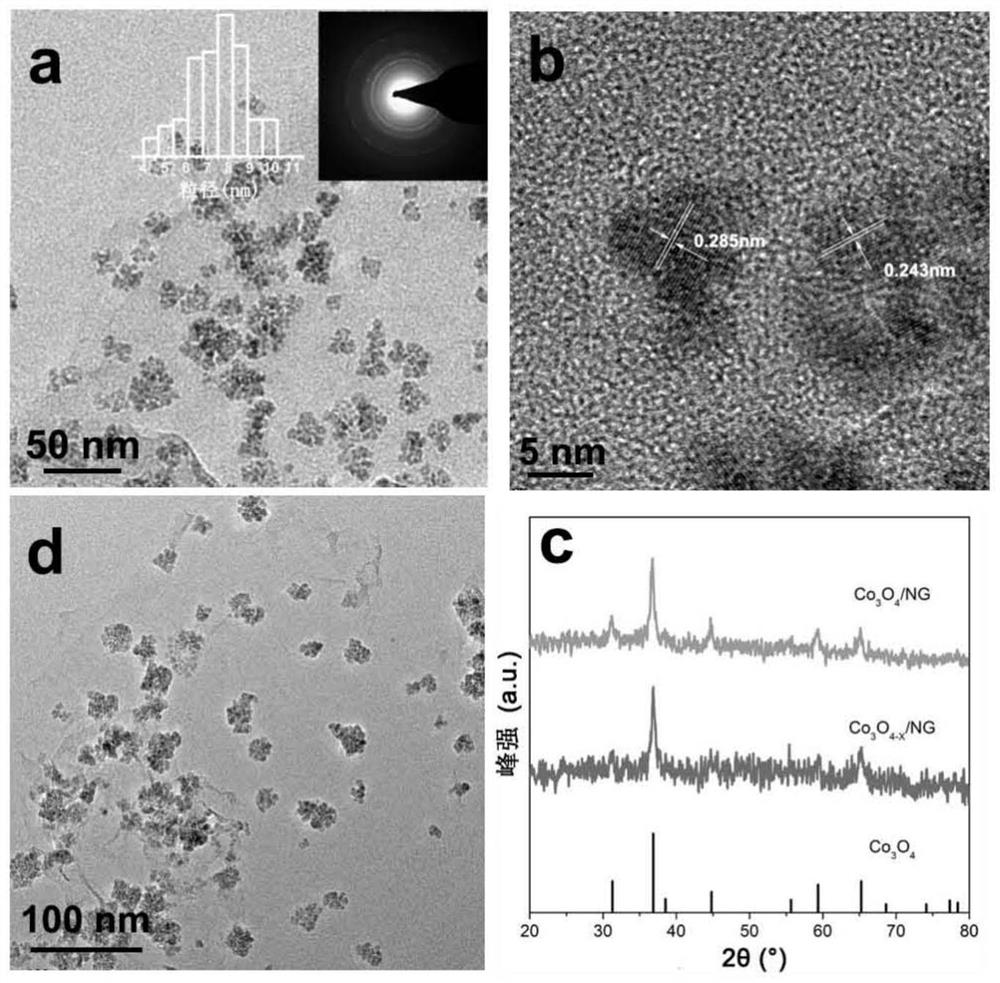

[0023] A method for preparing laser-synthesized oxygen-vacancy tunable tricobalt tetroxide nitrogen-doped graphene, comprising the following steps:

[0024] (1) Use graphite oxide to ultrasonically disperse in absolute ethanol to make a suspension of 0.33mg / ml, take 24ml of the suspension and add 1.2ml of 0.2M cobalt acetate solution, 0.5ml of 30% NH 4 OH solution and 0.7ml deionized water, oil bath at 80°C for 10h;

[0025] (2) Pour the solution obtained in step (2) into a reaction kettle, and react at 150° C. for 3 hours;

[0026] (3) Perform high-speed centrifugation on the sample obtained in step (3) at 12,000 to 20,000 rpm, then repeatedly wash with deionized water for 3 to 4 times, obtain a precipitate and freeze-dry;

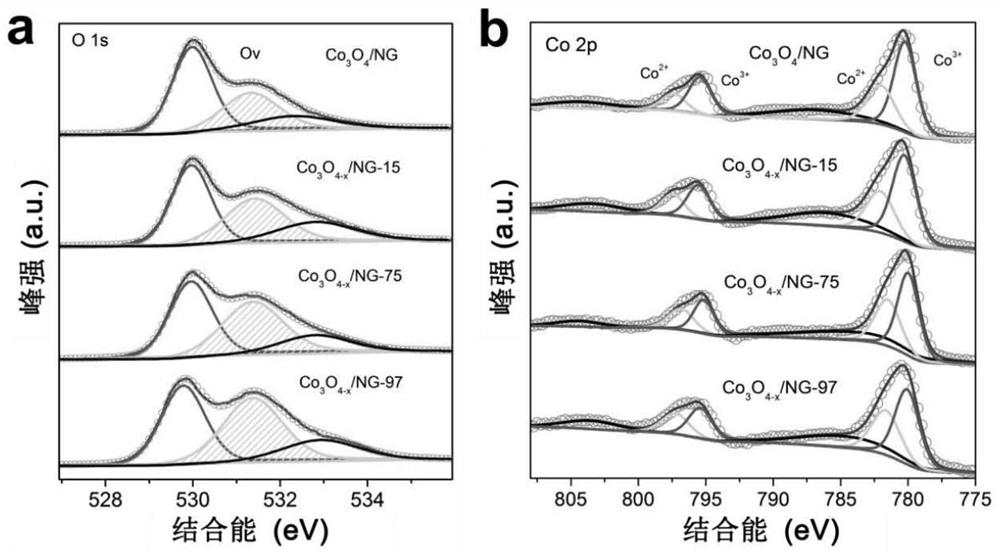

[0027] (4) Mix the sample obtained in step (3) with deionized water in a mass ratio of 1:3 and put it into a test tube. Under magnetic stirring, irradiate the solution with nanosecond parallel pulse laser 15mJ energy for 15min, and the magnetic stirring ...

Embodiment 2

[0030] A preparation method for laser synthesis of oxygen vacancy adjustable tricobalt tetroxide nitrogen-doped graphene, its basic steps are the same as in Example 1, the difference is that in step (4) irradiate the solution with nanosecond parallel pulse laser 75mJ energy for 15min, and then step Same as Example 1.

Embodiment 3

[0032] A preparation method for laser synthesis of oxygen vacancy adjustable tricobalt tetroxide nitrogen-doped graphene, its basic steps are the same as in Example 1, the difference is that in step (4), the solution is irradiated with nanosecond parallel pulse laser 97mJ energy for 5min, and the following steps Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com