Surgical vacuum aspiration device

A suction device and negative pressure technology, applied in the direction of suction equipment, suction containers, coatings, etc., can solve the problems of affecting medical staff's operation, liquid collection bottles are easy to dump, and pollute the operating room, so as to avoid the spread of iatrogenic viruses, Guaranteeing the service life and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

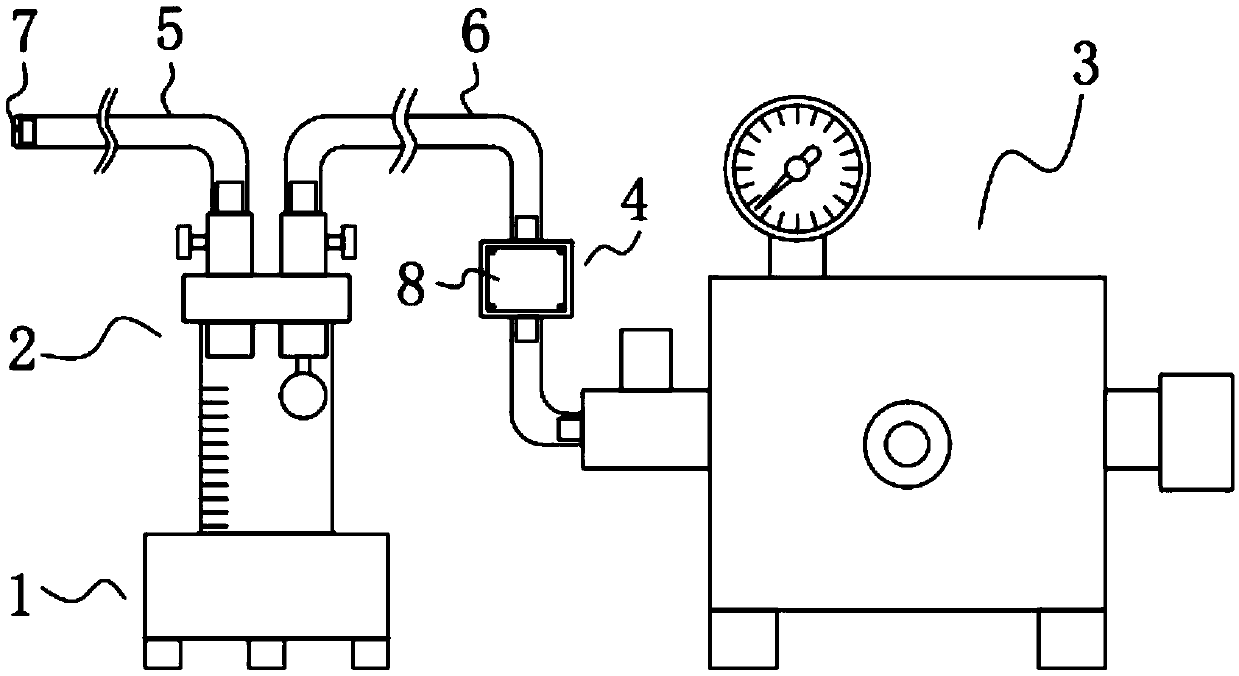

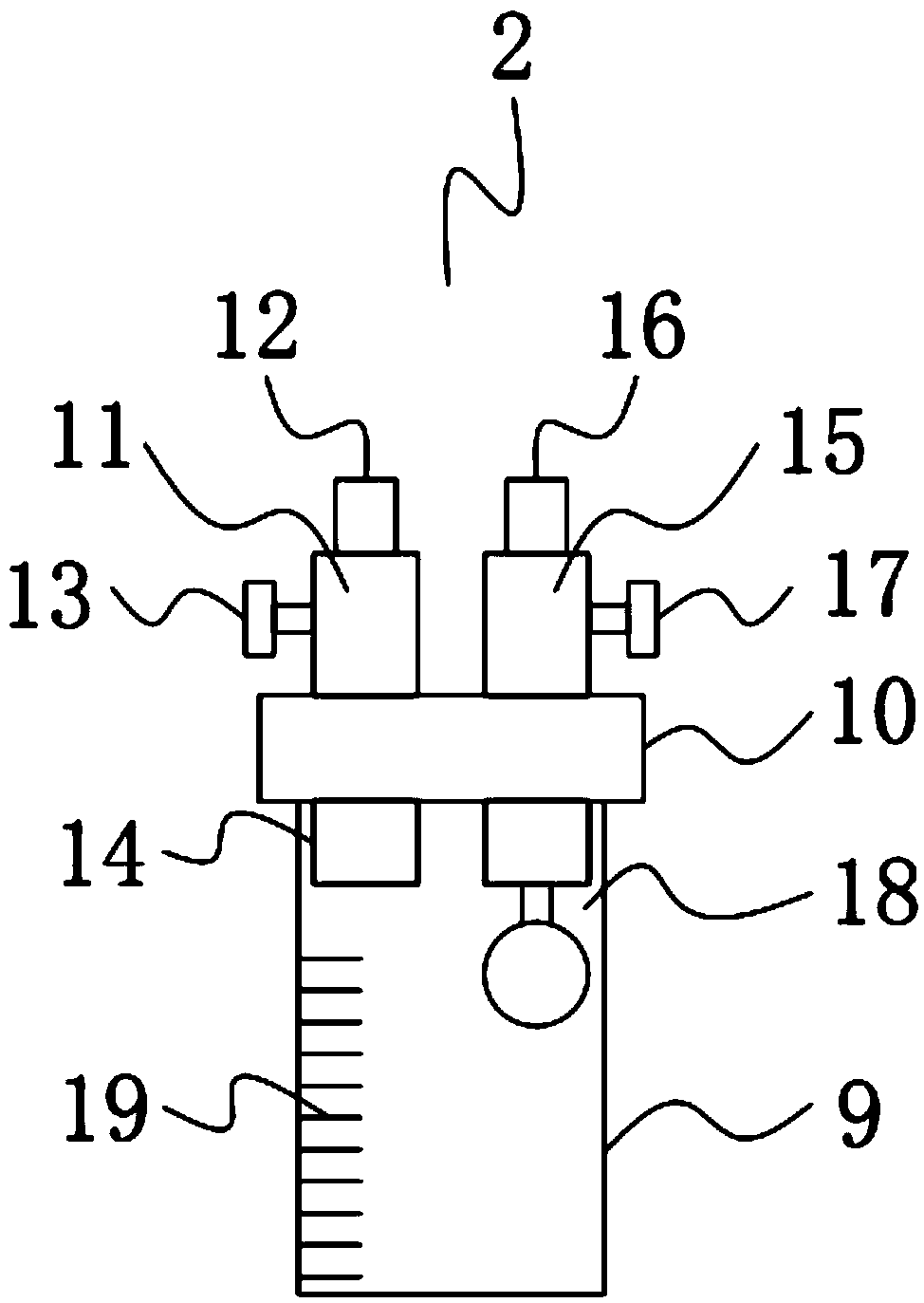

[0058] The following is attached Figure 1-10 The present invention is described in further detail.

[0059] A surgical vacuum suction device, such as Figure 1-10 As shown, it includes a bottom support part 1, a liquid collection device 2 and a negative pressure generating device 3. The liquid collection device 2 is detachably installed on the upper part of the bottom support part 1, and the liquid collection device 2 and the negative pressure The pressure generating device is connected in 3 phases;

[0060] The bottom support part 1 includes a cylindrical base 32, the upper part of the cylindrical base 32 is provided with a cylindrical groove 33, and the bottom of the cylindrical base 32 is installed at an equal angle with the center point of the bottom as the center of the circle. a rubber foot 34;

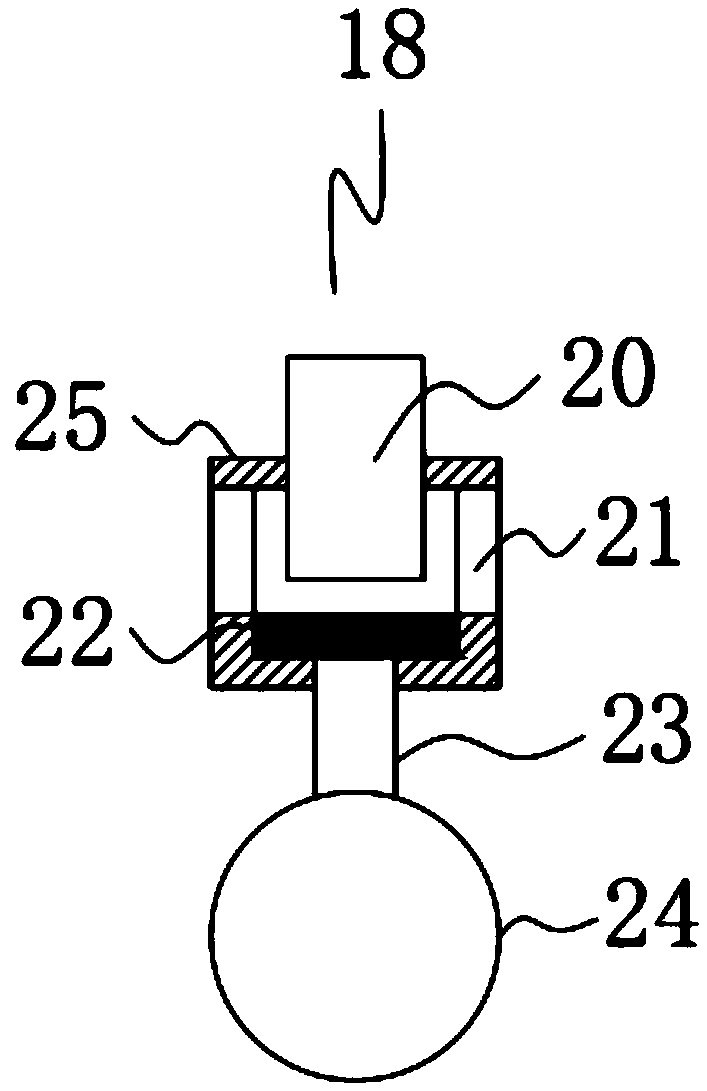

[0061] The liquid collection device 2 includes a liquid collection bottle 9 detachably installed inside the cylindrical groove 33, the upper end of the liquid collection bot...

Embodiment 2

[0073] The difference from Example 1 is that the surface of the shell 35 is also provided with an anti-corrosion layer, and the anti-corrosion layer is prepared by the following method:

[0074] Take the following raw materials and weigh them by weight: 35 parts of acrylic resin, 12 parts of calcium carbonate, 15 parts of p-toluenesulfonic acid powder, 6 parts of mica powder, 18 parts of phenolic resin, 3 parts of glycerin, 8 parts of alcohol ester twelve, trichloro 1 part of ferric chloride solution and 40 parts of water;

[0075] S1, add the weighed glycerin, ferric chloride solution, alcohol ester twelve and water into the mixer and stir for 20min, the stirring speed is 600r / min, and the mixed solution is obtained;

[0076] S2, adding acrylic resin, calcium carbonate, p-toluenesulfonic acid powder, mica powder and phenolic resin into a ball mill for fine grinding until the particle diameter is not greater than 40um to obtain a mixed powder material;

[0077] S3. Add the mi...

Embodiment 3

[0082] The difference from Example 2 is the preparation of the anti-corrosion layer, and its specific preparation method is as follows:

[0083] Take the following raw materials and weigh them by weight: 40 parts of acrylic resin, 16 parts of calcium carbonate, 18 parts of p-toluenesulfonic acid powder, 8 parts of mica powder, 22 parts of phenolic resin, 4 parts of glycerin, 10 parts of alcohol ester twelve, trichloro 2 parts of ferric chloride solution and 50 parts of water;

[0084] S1, add the weighed glycerin, ferric chloride solution, alcohol ester twelve and water into the mixer and stir for 25min, the stirring speed is 700r / min, and the mixed solution is obtained;

[0085] S2, adding acrylic resin, calcium carbonate, p-toluenesulfonic acid powder, mica powder and phenolic resin into a ball mill for fine grinding until the particle diameter is not greater than 40um to obtain a mixed powder material;

[0086] S3. Add the mixed powder material prepared in step S2 to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com