Conductor section and stator assembly with same, and motor

A conductor and component technology, applied in the field of motors, can solve the problems of poor insulation, small bending rounded corners, easy damage to the surface paint of flat copper wires, etc., to achieve the effect of ensuring insulation performance, facilitating welding, and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

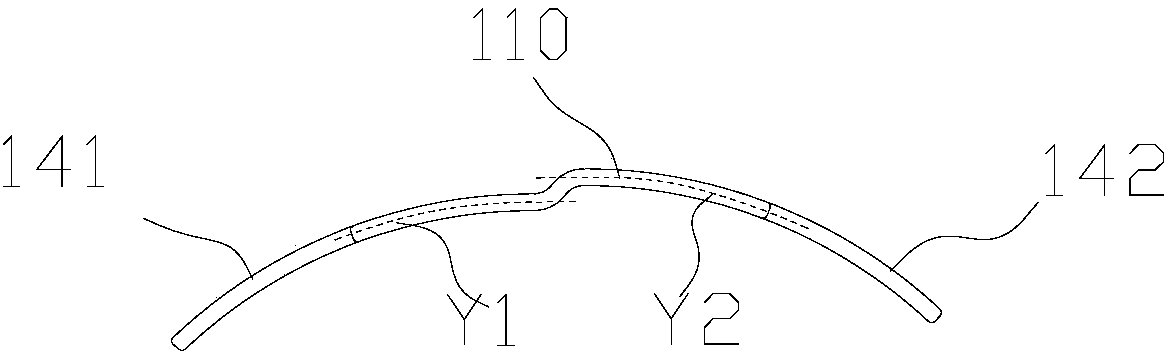

[0109] like Figure 1a As shown, the conductor segment 100 according to this embodiment includes a bent portion 110 , a first in-slot portion 120 and a second in-slot portion 130 . In this example, if Figure 1a and 2 As shown, the conductor segment 100 is made of flat copper wire.

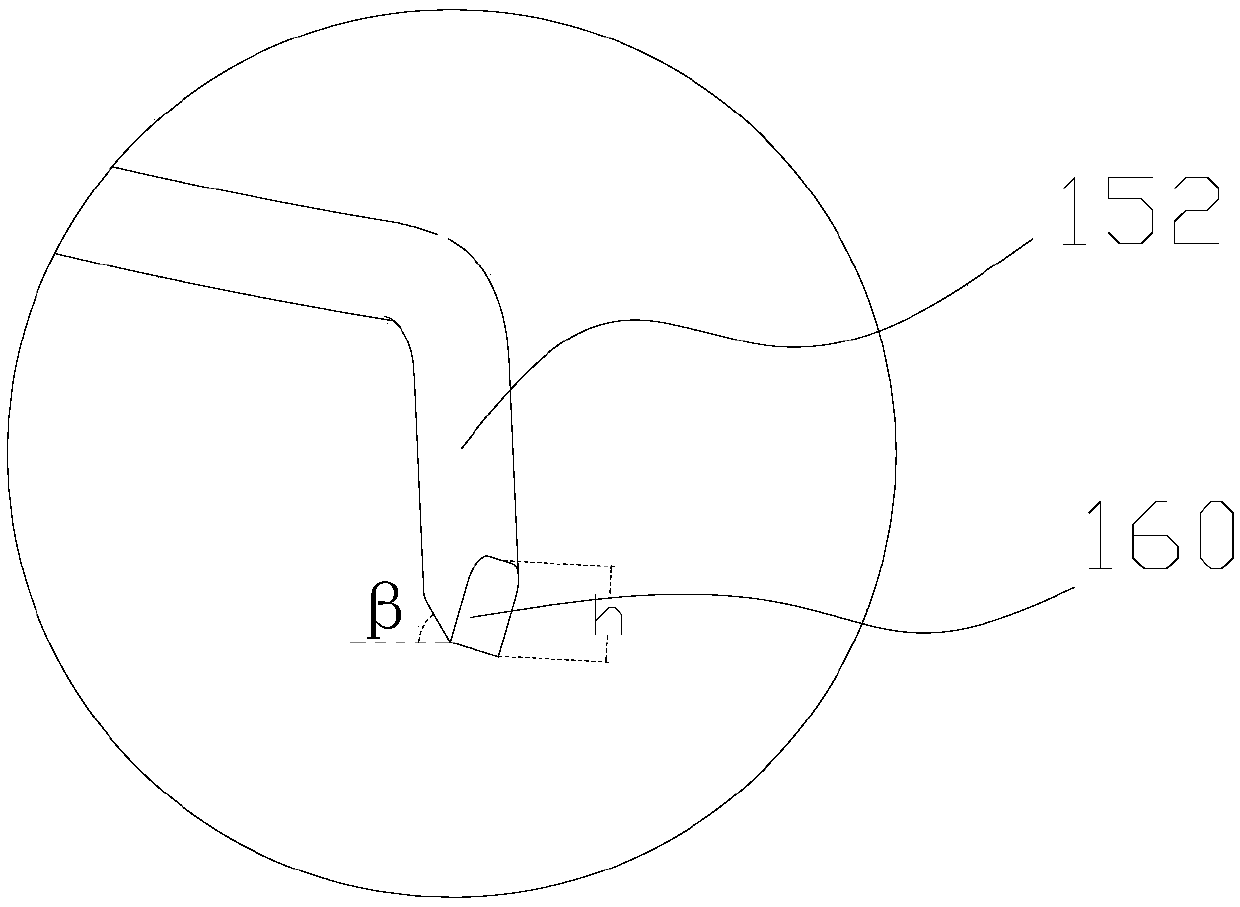

[0110] like figure 2 and Figure 4a As shown, the bending part 110 includes a first layer section 111, a second layer section 112 and a connecting section 113 connected between the first layer section 111 and the second layer section 112, and the first layer section 111 and the second layer section 112 are arc-shaped. The first in-trough part 120 is connected to an end of the first layer section 111 away from the connecting section 113 , and the second in-trough part 130 is connected to an end of the second layer section 112 away from the connecting section 113 .

[0111] The conductor segment 100 also includes: a first connecting portion 141 and a second connecting portion 142, a first weldi...

Embodiment 2

[0120] like Figure 1a As shown, the conductor segment 100 according to this embodiment includes a bent portion 110 , a first in-slot portion 120 and a second in-slot portion 130 . In this example, if Figure 1a and 2 As shown, the conductor segment 100 is made of flat copper wire.

[0121] like figure 2 and Figure 4a As shown, the bending part 110 includes a first layer section 111, a second layer section 112 and a connecting section 113 connected between the first layer section 111 and the second layer section 112, and the first layer section 111 and the second layer section 112 are arc-shaped. The first in-trough part 120 is connected to an end of the first layer section 111 away from the connecting section 113 , and the second in-trough part 130 is connected to an end of the second layer section 112 away from the connecting section 113 .

[0122] The conductor segment 100 also includes: a first connecting portion 141 and a second connecting portion 142, a first weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com