Waste lithium ion battery electrolyte solution recovery treatment method

A lithium-ion battery, electrolyte recycling technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve problems such as equipment environment, human body hazards, etc., achieve a simple and novel process route, avoid volatilization loss, no two The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

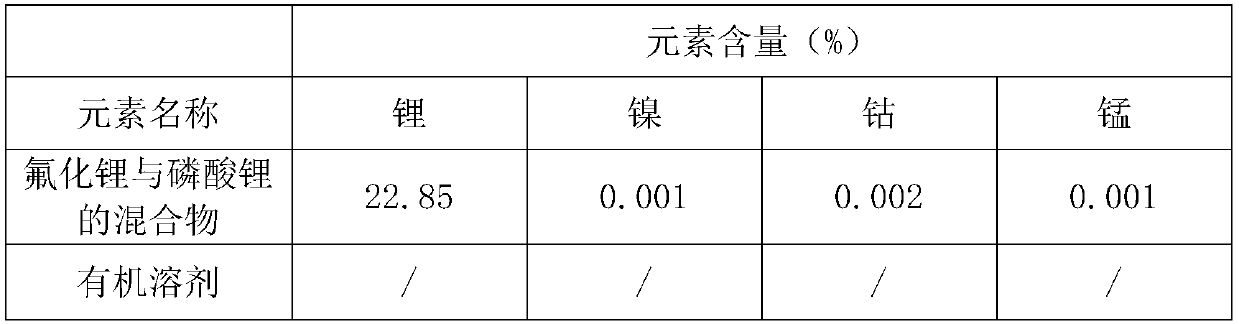

Embodiment 1

[0015] A method for recovering and treating the electrolyte of a waste lithium ion battery. The electrolyte used in the waste lithium ion battery of this embodiment is lithium hexafluorophosphate, and the waste lithium ion battery is placed in liquid nitrogen and frozen for 40 minutes until the electrolyte in the waste lithium ion battery is Solid state, then take out the waste lithium-ion battery and put it into a low-temperature pulverizer, and pulverize the solid electrolyte before it is liquefied or vaporized to obtain a pulverized mixture. The pulverization time is controlled at 2 minutes, and the temperature of the low-temperature pulverizer is controlled at -58°C. Place the pulverized mixture in a container containing a saturated lithium carbonate solution at a rate of 4.5ml of saturated lithium carbonate solution per gram of the pulverized mixture, and soak for 35 minutes until the lithium hexafluorophosphate electrolyte completely reacts to form lithium fluoride and lit...

Embodiment 2

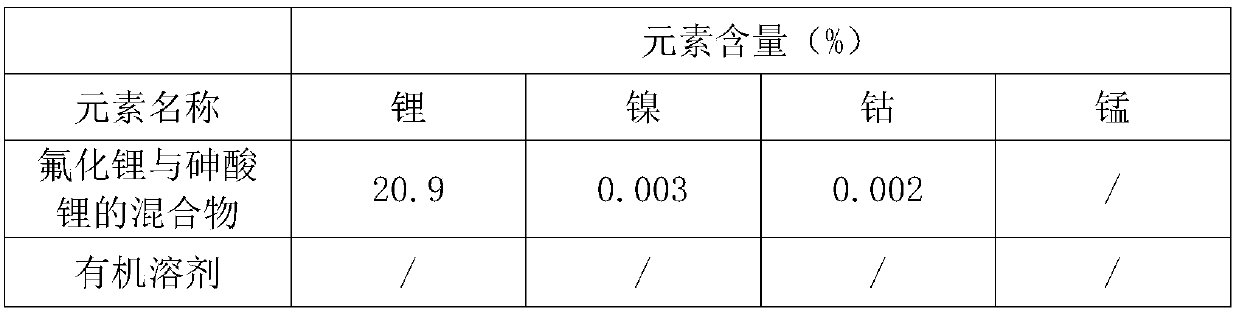

[0020] A method for recovering and treating the electrolyte of a waste lithium ion battery, the steps of which are basically the same as those of the method for recovering and treating the electrolyte of a waste lithium ion battery in Example 1, the difference being that:

[0021] 1. The electrolyte used in waste lithium-ion batteries is lithium hexafluoroarsenate;

[0022] 2. The freezing time of used lithium-ion batteries in liquid nitrogen is 25 minutes;

[0023] 3. The crushing time of waste lithium-ion batteries in the low-temperature pulverizer is controlled at 3 minutes, and the temperature of the low-temperature pulverizer is controlled at -60°C;

[0024] 4. Each gram of pulverized mixture needs 8ml of saturated lithium carbonate solution. The soaking time of the pulverized mixture in a container filled with saturated lithium carbonate solution is 25 minutes. Lithium hexafluoroarsenate reacts completely to form lithium fluoride and lithium arsenate;

[0025] 5. The me...

Embodiment 3

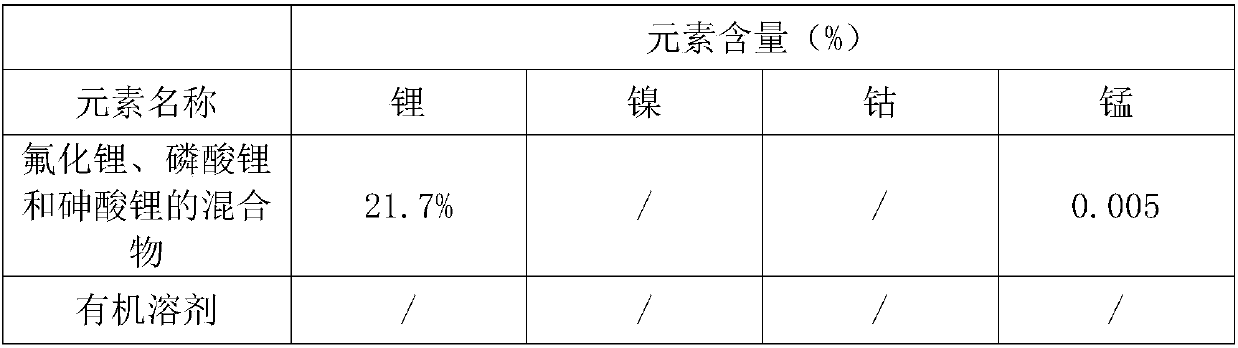

[0031] A method for recovering and treating the electrolyte of a waste lithium ion battery, the steps of which are basically the same as those of the method for recovering and treating the electrolyte of a waste lithium ion battery in Example 1, the difference being that:

[0032] 1. Among the waste lithium-ion batteries, there are batteries using lithium hexafluorophosphate electrolyte and batteries using lithium hexafluoroarsenate electrolyte;

[0033] 2. The freezing time of waste lithium-ion batteries in liquid nitrogen is 60 minutes;

[0034] 3. The crushing time of waste lithium-ion batteries in the low-temperature pulverizer is controlled at 1.8 minutes;

[0035] 4. Each gram of crushed mixture needs 2ml of saturated lithium carbonate solution. The soaking time of the crushed mixture in a container filled with saturated lithium carbonate solution is 60 minutes. Lithium hexafluorophosphate and lithium hexafluoroarsenate react completely to form lithium fluoride, lithium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com