Crystal particle method and system

A detection system and die technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of inability to control the panel die defect rate, difficult die electrical testing, and difficulty in detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

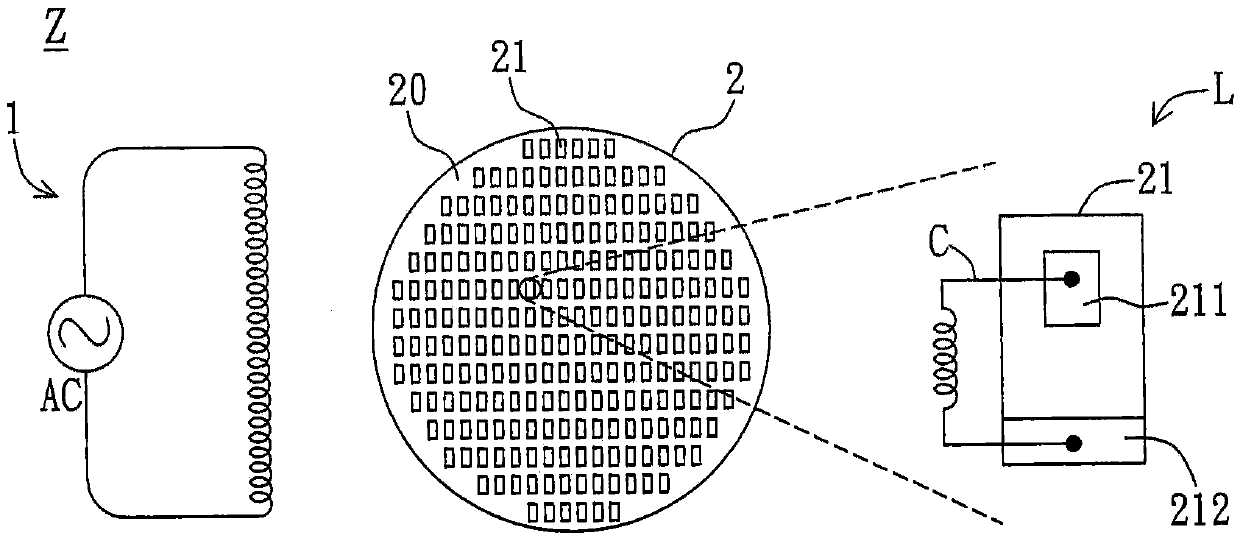

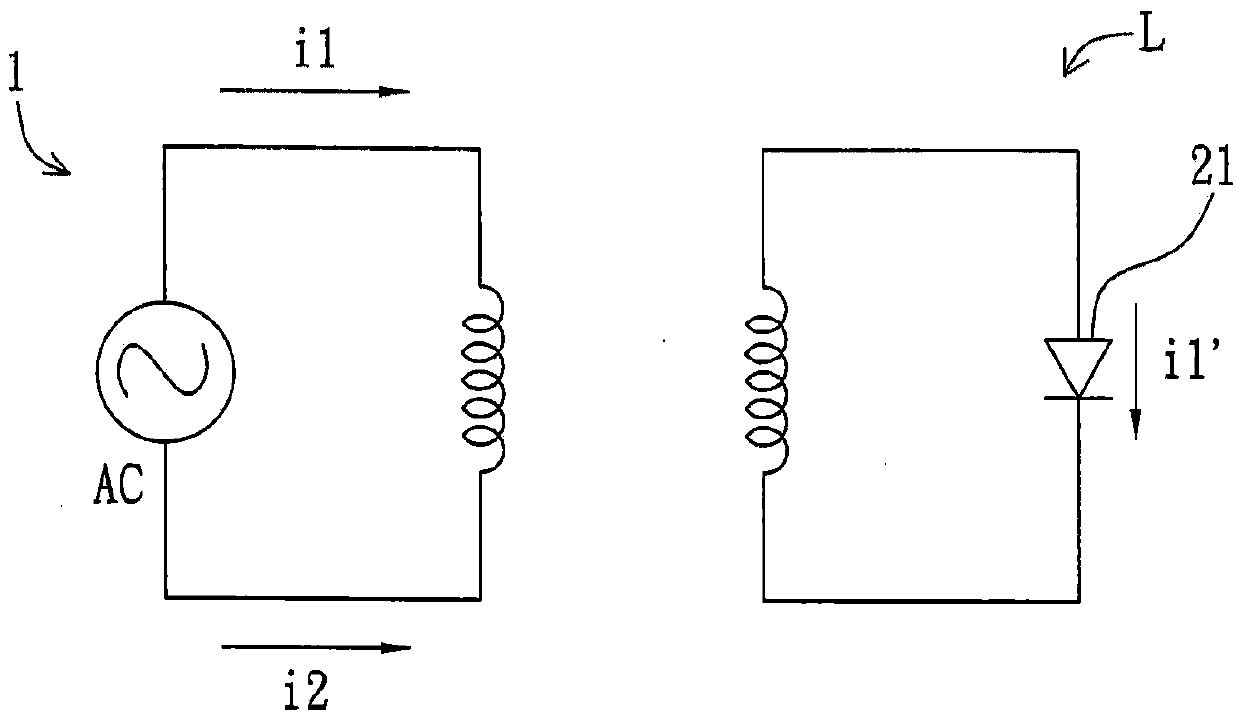

[0048] The following fit Figure 1 to Figure 3 The grain inspection system and method of the first embodiment of the present invention will be described. please see figure 1 , this embodiment provides a die inspection system Z, which has a coil 1 and a source wafer 2 . The aforementioned "source wafer" includes but is not limited to a silicon chip on which the die 21 is grown. The upper surface 20 of the source wafer 2 has a plurality of dies 21 . In this embodiment, the die 21 is a micro LED die, however, the present invention is not limited thereto; in other embodiments, the die 21 can be other types of semiconductor die.

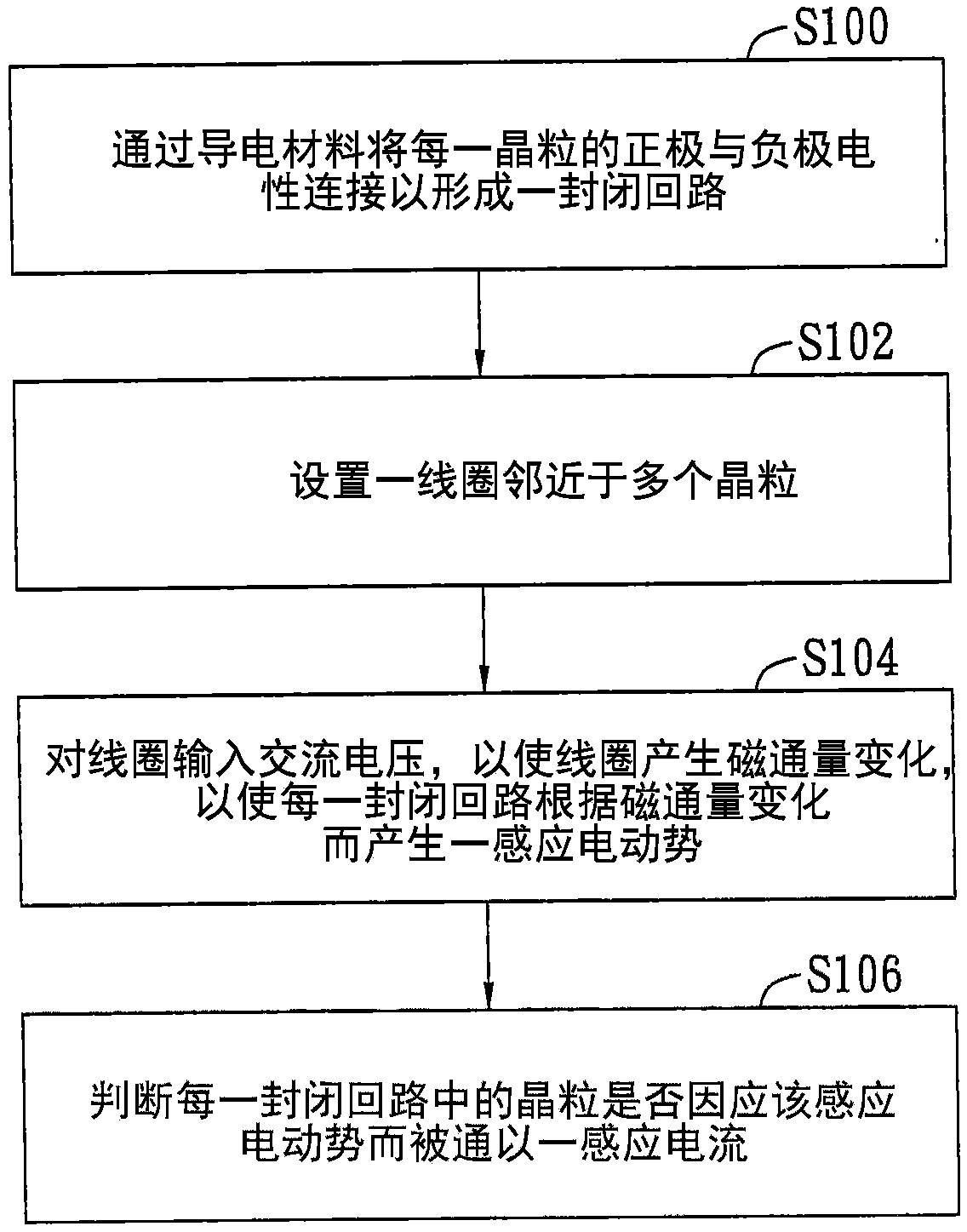

[0049] Please refer to figure 1 and figure 2 , this embodiment provides a grain inspection method using the grain inspection system Z, the grain inspection method at least includes the following steps. Step S100: Electrically connect the positive electrode 211 and the negative electrode 212 of each crystal grain 21 through a conductive material C t...

no. 2 example

[0058] The following fit Figure 6 to Figure 17 The grain inspection system Z and the grain inspection method provided by the second embodiment of the present invention will be described. See first Image 6 , the die detection system Z provided in this embodiment includes at least one coil 1 and a source wafer 2 . In this embodiment, among the plurality of dies 21 on the source wafer 2, every two adjacent dies 21 form a die pair 210, and each die pair 210 includes a first die 21A and a second die grain 21B.

[0059] The following fit Image 6 and Figure 7 The grain inspection method of the second embodiment is described, which uses the above-mentioned grain inspection system Z and includes at least the following steps. Step S200: Form a closed circuit between the first crystal grain 21A and the second crystal grain 21B of each crystal grain pair 210 through a conductive material, wherein the first crystal grain 21A in each crystal grain pair 210 is connected with the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com