Method for measuring the line width or the line spacing minimum distance of a high-density flexible printed substrate

A flexible printed substrate and flexible printing technology, applied in image data processing, instruments, calculations, etc., can solve problems such as heavy tasks, high difficulty, and error-prone, and achieve the effect of improving measurement accuracy and facilitating control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

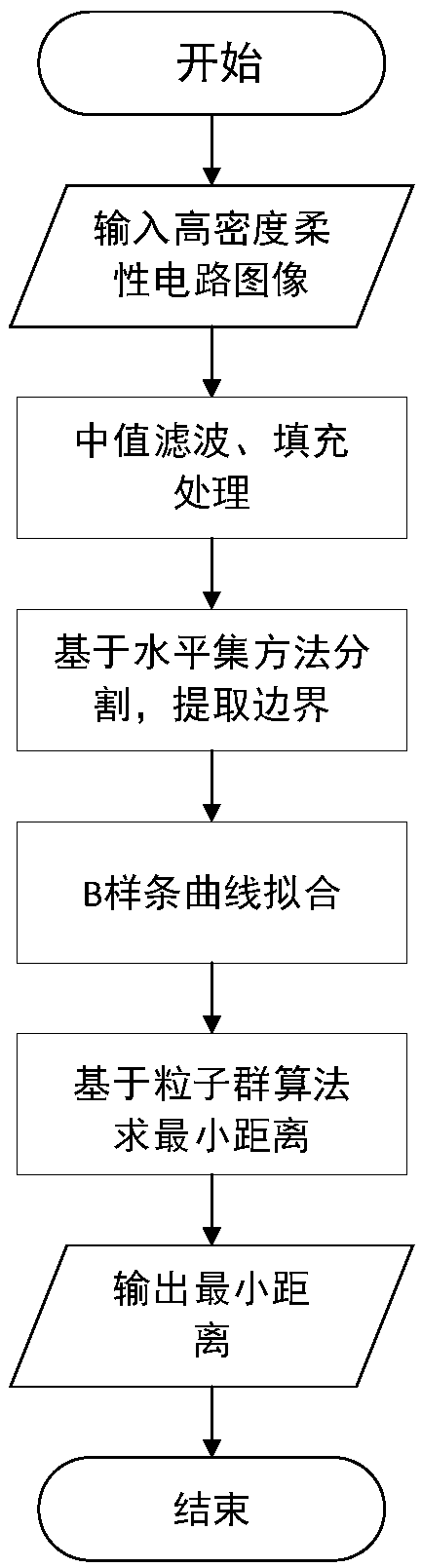

[0046] Such as Figure 1-Figure 4 As shown, a method for measuring the line width of a high-density flexible printed substrate or the minimum distance between lines includes the following steps:

[0047] S1 for the collected images of high-density flexible printed substrates such as Figure 5 As shown, the median filtering and morphological filling processing are performed in sequence; the processed image is as follows Figure 6 As shown, this step plays the role of enhancing the image of the flexible substrate, removing noise, protecting the edges, and reducing the adverse effects of oxidation on the flexible substrate.

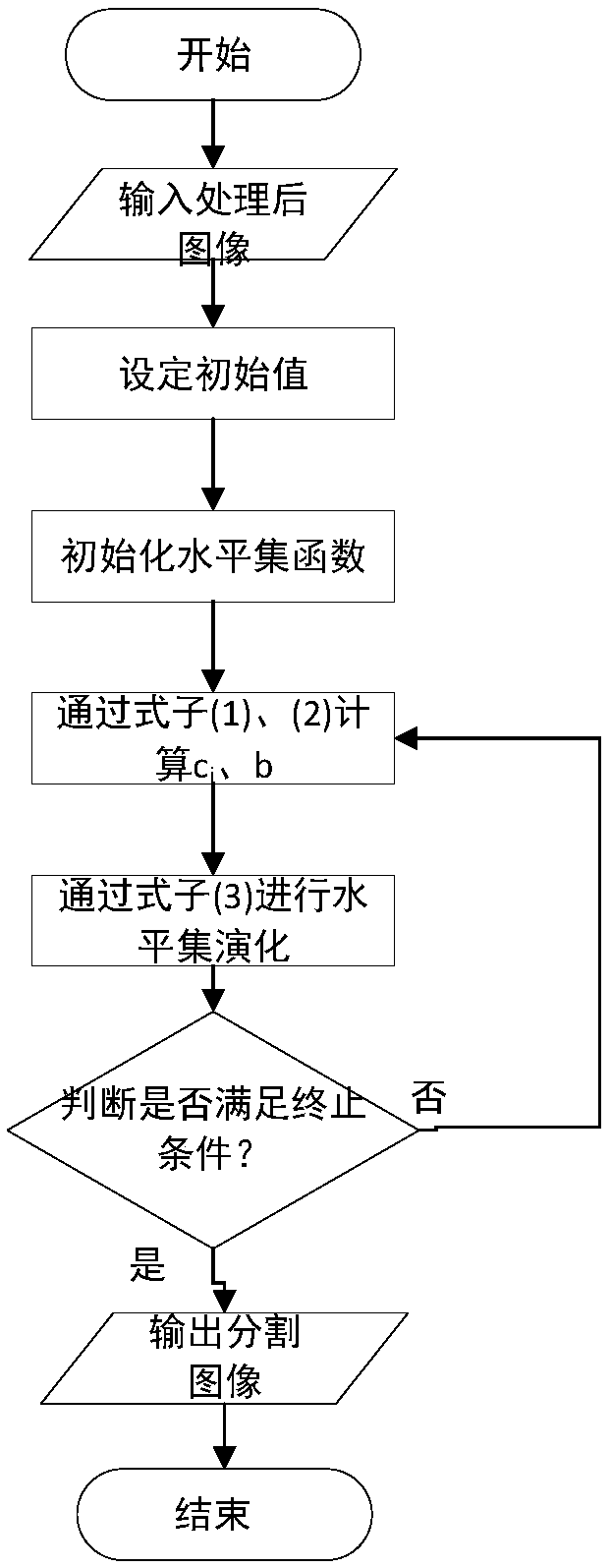

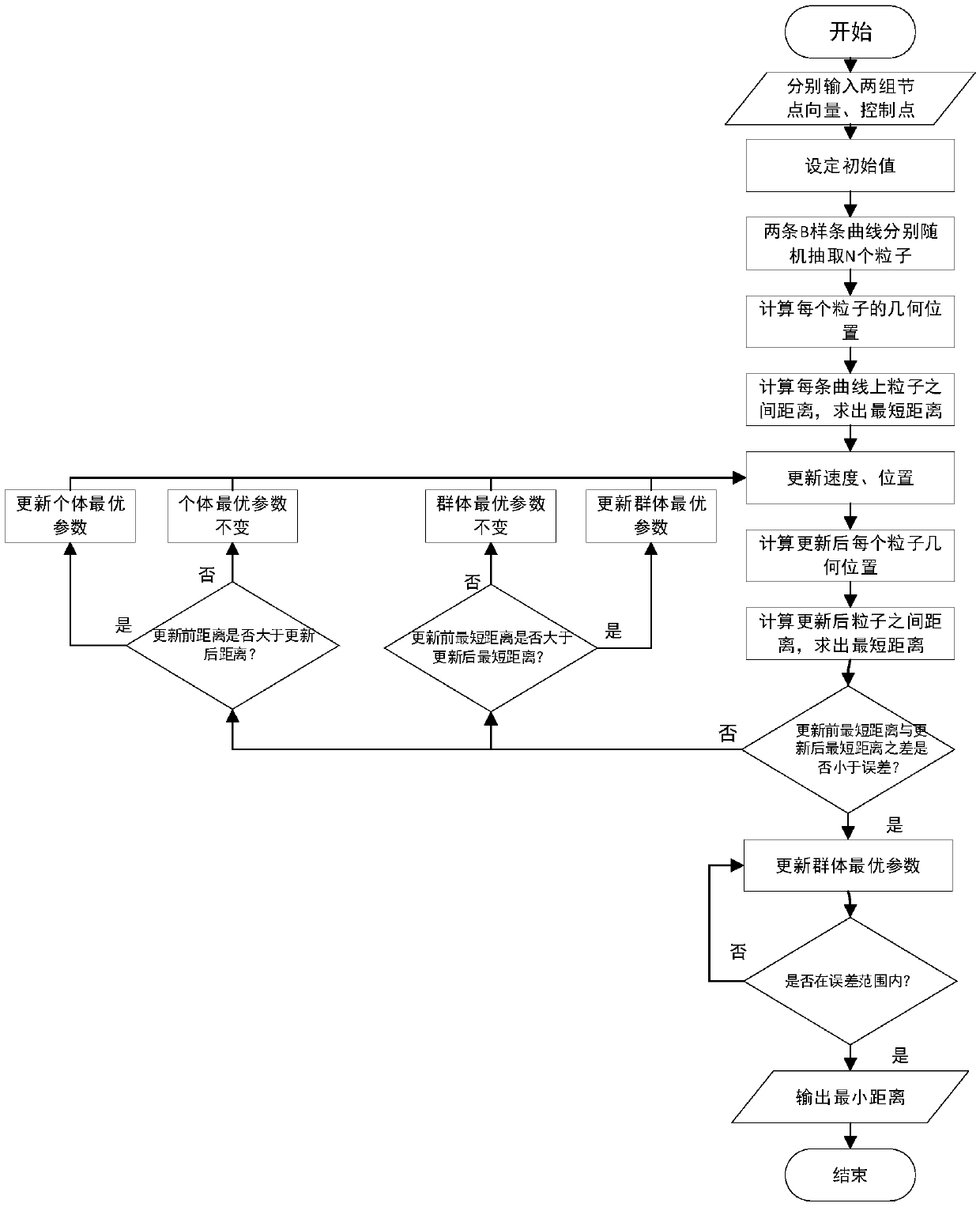

[0048] S2 uses the curve evolution theory and level set method to segment the processed image, and extracts the boundary coordinates of the wire, such as Figure 7 As shown, in this step, the variational method is used to minimize the energy functional, and the evolution level set function is driven. When the iteration condition is satisfied, the zero leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com