Anti-reflection film and optical component comprising anti-reflection film

A technology of anti-reflection film and optical components, which is applied in the directions of optical components, optics, transportation and packaging, etc. It can solve the problems of reducing reflectivity, difficulties, ripples in the visible area, and large influence of wavelength shift, so as to achieve high performance and reduce The effect of ghosting or flare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

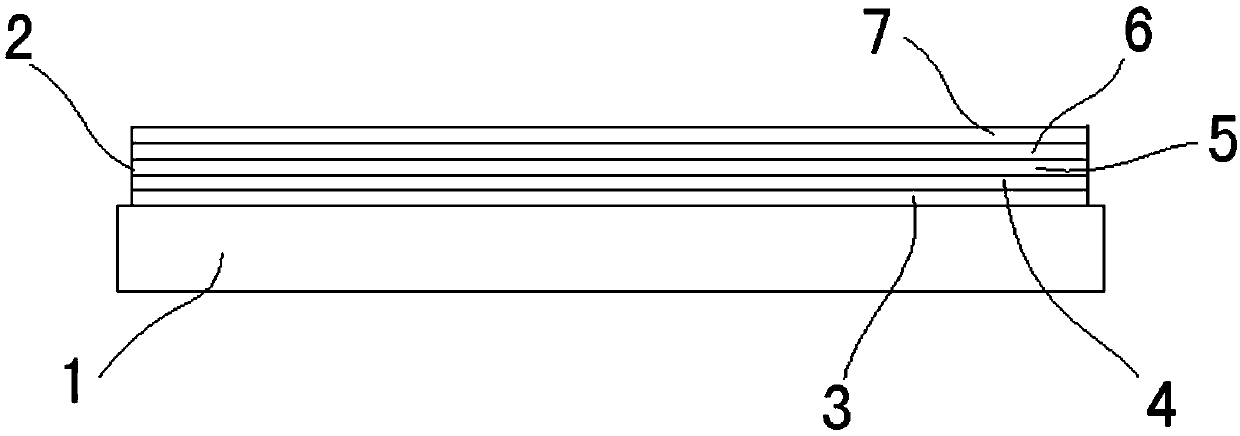

[0043] Embodiment one, such as figure 1 As shown, the anti-reflection film 2 disposed on the substrate layer 1 includes a five-layer structure, that is, a first low-reflection layer 3, a second low-reflection layer 4, and a third low-reflection layer 5 belonging to a multilayer film, and a protective film. The first protective film 6 and the second protective film 7 of the film.

Embodiment 2

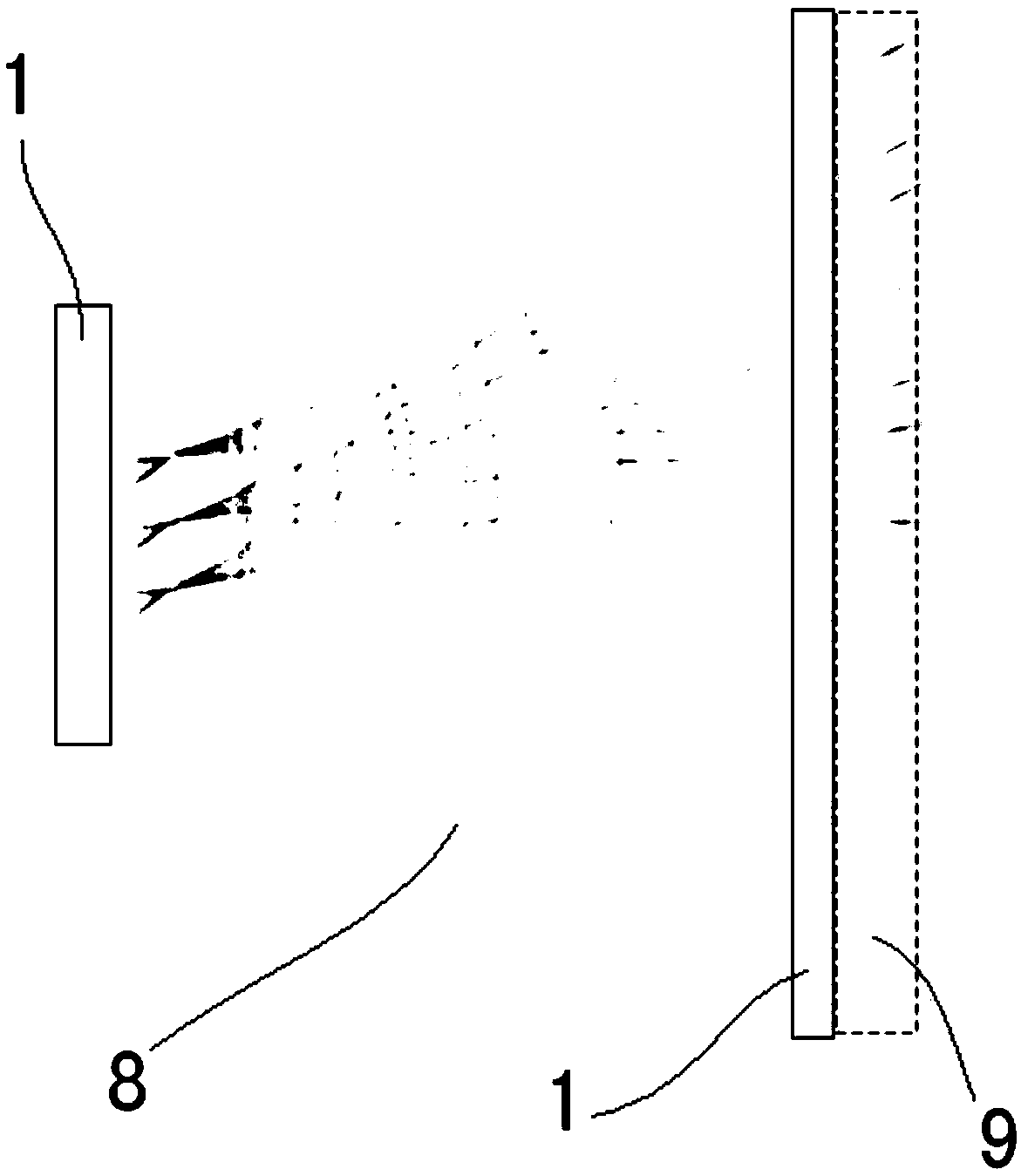

[0044] Embodiment two, such as figure 1 , figure 2 Shown, is the optical component 8 structure that adopts substrate layer 1 and anti-reflection film 2 of the present invention, one end of optical component 8 contacts with air layer 9, and optical component 8 two ends are respectively provided with substrate layer 1, and optical element 8 is contained in On the basis of lenses, optical filters, etc., at least one of the light entrance and exit surfaces of the substrate layer 1 includes an antireflection film 2, and the antireflection film 2 is formed from the substrate layer 1 side or the substrate layer 1 side to the On the air layer 9 side, the first low-reflection layer 3, the second low-reflection layer 4, the third low-reflection layer 5, the first layer of protective film 6, and the second layer of protective film 7 are stacked on the substrate layer 1 to form .

[0045] The specific implementation process is that in this embodiment, the first low-reflection layer 3 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com