Preparation method and product of a flexible humidity sensor

A humidity sensor and flexible technology, which is applied in the field of preparation of flexible humidity sensors, can solve the problems of no elastic-plastic deformation such as stretching and bending, slow response speed of electrical humidity sensors, and high stability of humidity sensors, etc., to achieve flexibility and extension Good performance, easy quality control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

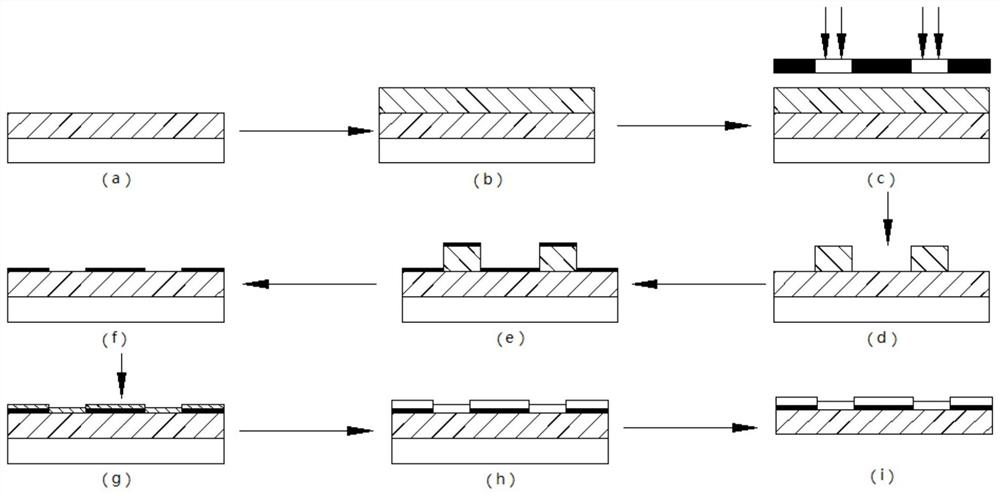

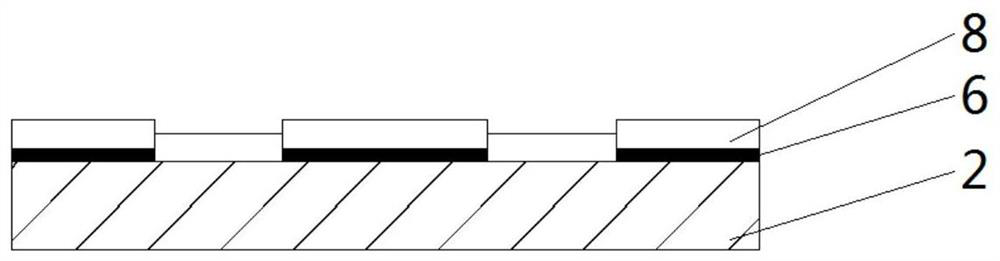

[0044] A method for preparing a flexible humidity sensor of this embodiment, the specific steps of the method are as follows:

[0045] Step 1, photolithography and development

[0046] Attach a layer of PET film on the surface of the cleaned transparent glass substrate, and then spin-coat a layer of photoresist on the PET, and go through the steps of pre-baking, exposure, post-baking, and post-cooling development to obtain electrodes arranged in an array mask graphics.

[0047] Step 2, remove the residual glue

[0048] A plasma stripper is used to remove the remaining unexposed photoresist and activate the surface of the substrate to enhance the adhesion between the subsequent sputtered metal electrodes and the substrate.

[0049] Step 3, sputtering to prepare metal electrodes

[0050] A sputtering layer of metal is deposited on the above substrate by sputtering process, the sputtering power is adjusted to 50W, the thickness of the sputtered metal electrode is 5nm by adjust...

Embodiment 2

[0057] A method for preparing a flexible humidity sensor of this embodiment, the specific steps of the method are as follows:

[0058] Step 1, photolithography and development

[0059] Attach a layer of PET film on the surface of the cleaned transparent glass substrate, and then spin-coat a layer of photoresist on the PET, and go through the steps of pre-baking, exposure, post-baking, and post-cooling development to obtain electrodes arranged in an array mask graphics.

[0060] Step 2, remove the residual glue

[0061] A plasma stripper is used to remove the remaining unexposed photoresist and activate the surface of the substrate to enhance the adhesion between the subsequent sputtered metal electrodes and the substrate.

[0062] Step 3, sputtering to prepare metal electrodes

[0063] Deposit and sputter a layer of metal on the above substrate by sputtering process, adjust the sputtering power to 200W, adjust the vacuum degree and time of sputtering so that the thickness o...

Embodiment 3

[0070] A method for preparing a flexible humidity sensor of this embodiment, the specific steps of the method are as follows:

[0071] Step 1, photolithography and development

[0072] Attach a layer of PET film on the surface of the cleaned transparent glass substrate, and then spin-coat a layer of photoresist on the PET, and go through the steps of pre-baking, exposure, post-baking, and post-cooling development to obtain electrodes arranged in an array mask graphics.

[0073] Step 2, remove the residual glue

[0074] A plasma remover is used to remove residual photoresist and activate the surface of the substrate to enhance the adhesion between the subsequent sputtered metal electrodes and the substrate.

[0075] Step 3, deposition and sputtering to prepare metal electrodes

[0076] Deposit and sputter a layer of metal on the above substrate by sputtering process, adjust the sputtering power to 100W, adjust the vacuum degree and time of sputtering so that the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com