Prepreg splicing strength detection method for automatic placement

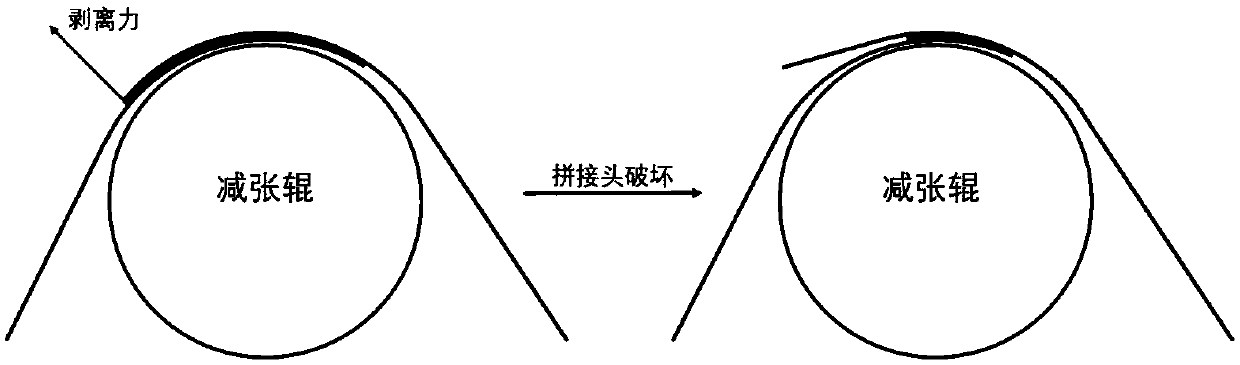

A technology of splicing strength and detection method, which is applied in the directions of measuring devices, analyzing materials, using mechanical devices, etc., can solve the problems of insufficient quantitative characterization of prepreg splicing strength, and achieve simple and reliable testing methods, ensuring accuracy and guidance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

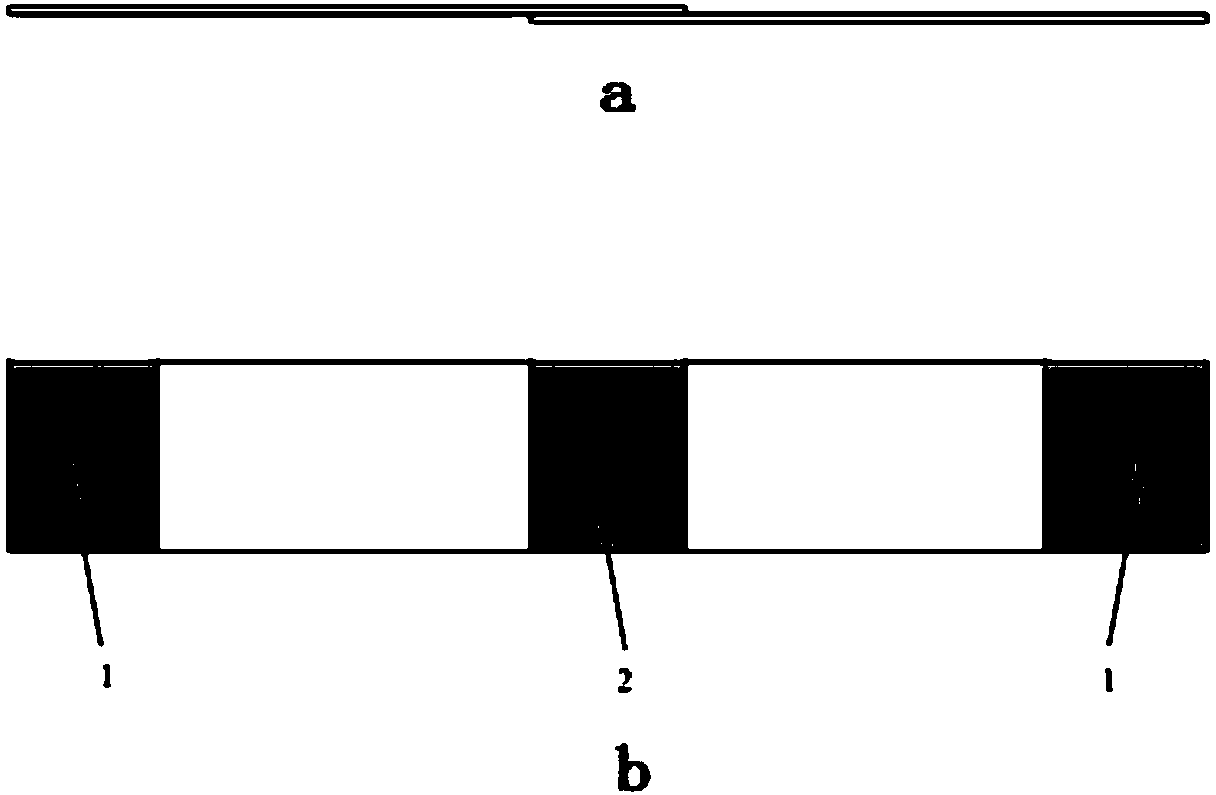

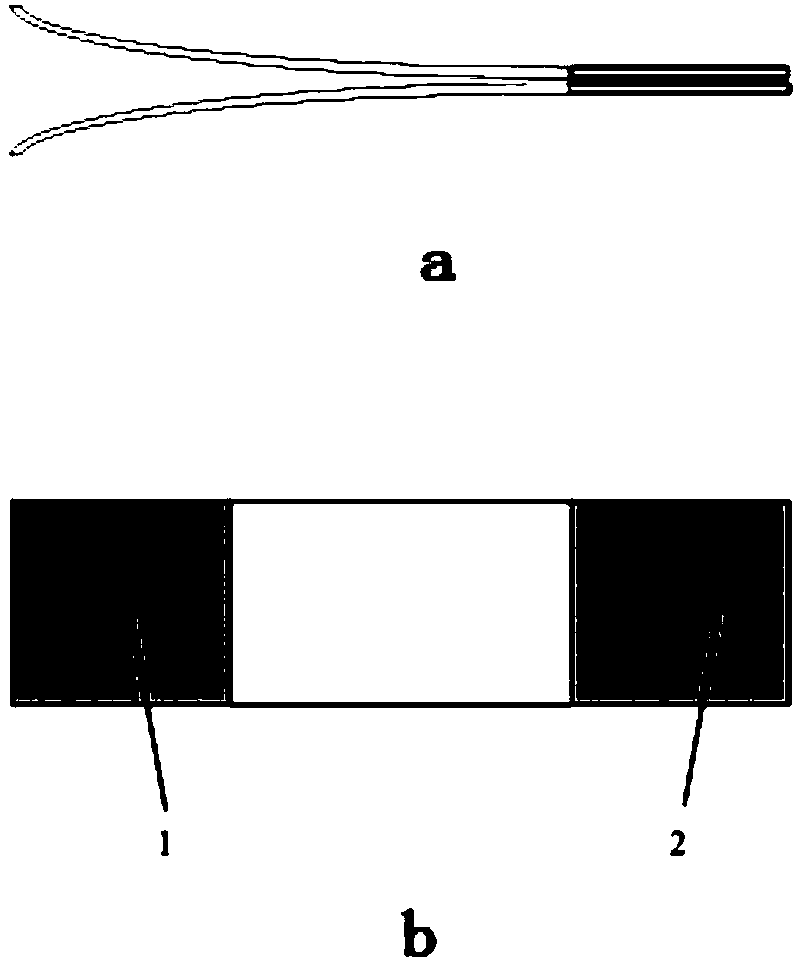

[0029] Put the two prepreg tows according to the figure 2 and image 3 The method and size of the pre-bonded pre-bonded sample and peeled sample, the length of the bonding surface of the two prepreg tows is 40mm, the main axis direction should be the same as the direction of the carbon fiber in the prepreg tow. Then put the bonding area 2 into the mechanical hot-pressing platform for hot-pressing splicing, and use polytetrafluoroethylene release cloth to isolate the prepreg tow and the hot-pressing platform. The splicing temperature is 30°C, the pressure is 0.2MPa, and the time is 3min. The obtained splice strength test specimens were tested with a tensile tester and a peel strength tester respectively. The distance between the end of the clamping area 1 and the nearest lap joint was 50mm, the test environment temperature was 15°C, and the load loading rate was 0.1m / min. The test results show that the tensile failure strength of the prepreg splicing strength sample is 202...

Embodiment 2

[0031] Put the two prepreg tows according to the figure 2 and image 3 The method and size of the two prepreg tows should be manually pre-bonded into a flat tensile sample and a peeled sample. The length of the bonding surface of the two prepreg tows is 25mm, and the direction of the main axis should be the same as that of the carbon fibers in the prepreg tows. Then put the bonding area 2 into a mechanical hot-pressing platform for hot-pressing splicing, and use a PE film to isolate the prepreg tow from the hot-pressing platform. The splicing temperature is 45°C, the pressure is 0.3MPa, and the time is 1min. The obtained splice strength test specimens were tested with a tensile tester and a peel strength tester respectively. The distance between the end of the clamping area 1 and the nearest lap joint was 90mm, the test environment temperature was 5°C, and the load loading rate was 4m / min. The test results show that the tensile failure strength of the prepreg splicing str...

Embodiment 3

[0033] Put the two prepreg tows according to the figure 2 and image 3The method and size of the two prepreg tows should be manually pre-bonded into a flat tensile sample and a peeled sample. The length of the bonding surface of the two prepreg tows should be 55mm, and the direction of the main axis should be the same as that of the carbon fibers in the prepreg tows. Then put the bonding area 2 into a mechanical hot-pressing platform for hot-pressing splicing, and use PP film to isolate the prepreg tow and the hot-pressing platform. The splicing temperature is 55°C, the pressure is 0.4MPa, and the time is 5min. The obtained splicing strength test specimens were tested using a tensile tester and a peel strength tester respectively. The distance between the end of the clamping area 1 and the nearest lap joint was 120mm, the test environment temperature was 20°C, and the load loading rate was 15m / min. The test results show that the tensile failure strength of the prepreg spl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com