Intelligent liquefied gas cooker

A liquefied gas and intelligent technology, which is applied in household appliances, household stoves/stoves, gaseous heating fuels, etc., can solve the problems of lack of user-specific processing mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

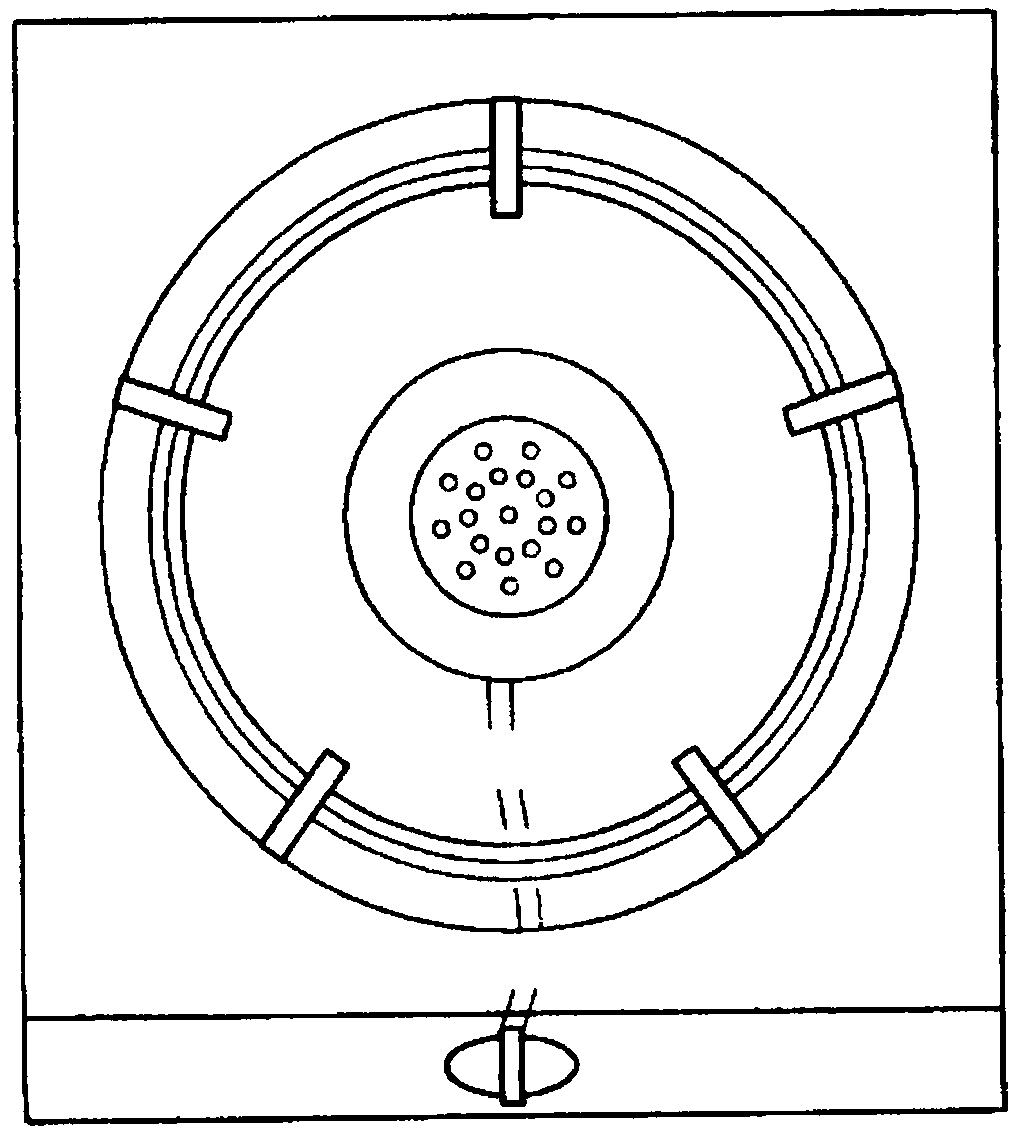

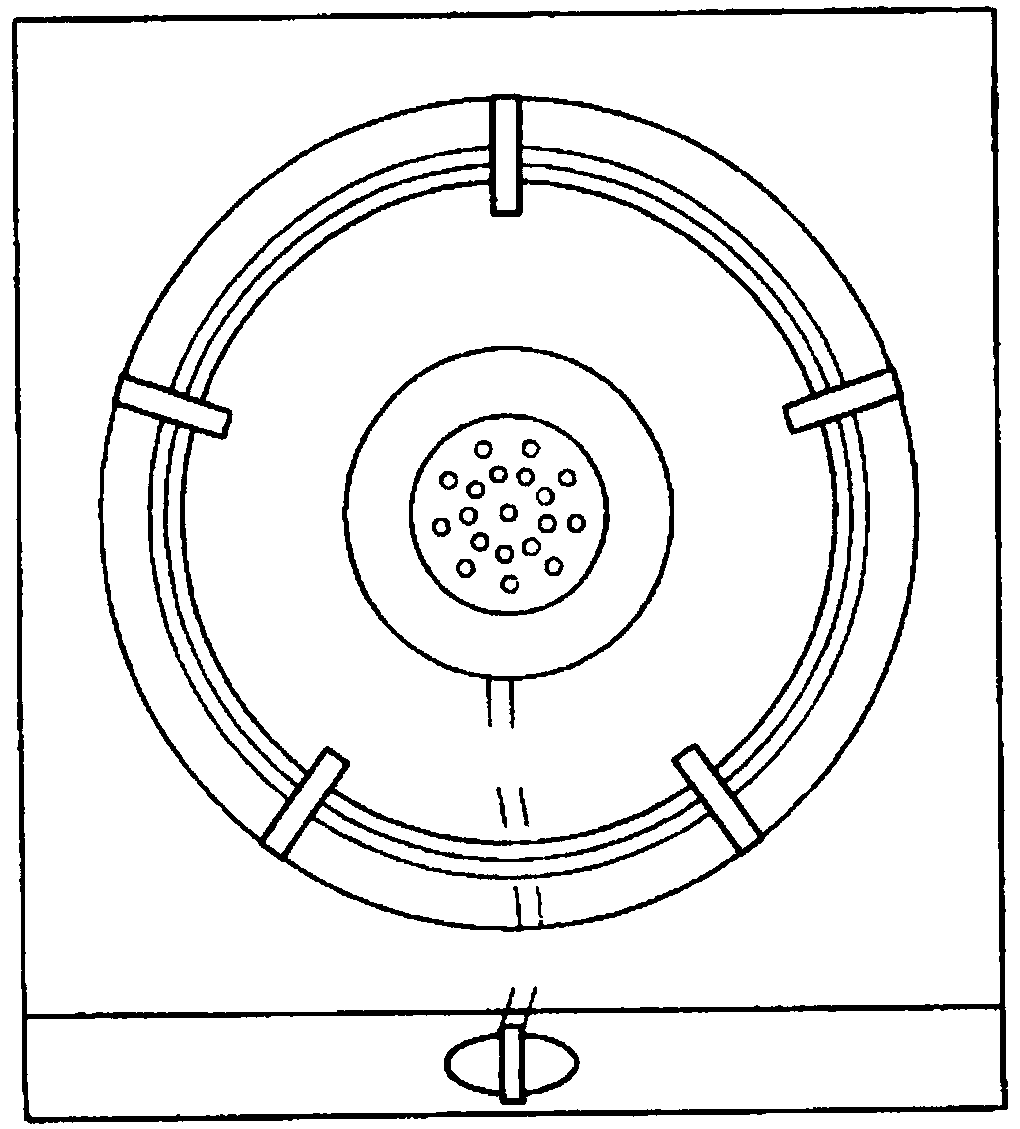

Image

Examples

Embodiment Construction

[0028] The embodiments of the intelligent liquefied gas cooktop of the present invention will be described in detail below with reference to the accompanying drawings.

[0029] Liquefied gas stoves are also called gas stoves. There are two ignition methods: electronic pulse ignition and piezoelectric ceramic ignition. Consumers are generally familiar with electronic pulse ignition. Most of the ignition devices used in built-in stoves ignite when they are twisted to a certain position. It is very simple and convenient, and the ignition hit rate is high, usually 100%, but this method requires Change the battery.

[0030] Piezoelectric ceramic ignitions are mostly used in tabletop stoves, and the biggest advantage is that they do not require batteries. However, the success rate of ignition is related to the ambient humidity, and it is not easy to ignite when the humidity is high. In addition, you need to hold down the switch to start the ignition, which is not as fast as electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com