High-reliability closed spool type dynamic pressure bearing

A dynamic pressure bearing, closed technology, used in shafts and bearings, sliding contact bearings, bearings in rotary motion, etc., can solve the problems of low stiffness and low start-stop reliability, achieve low friction coefficient, high travel accuracy, The effect of improving bearing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

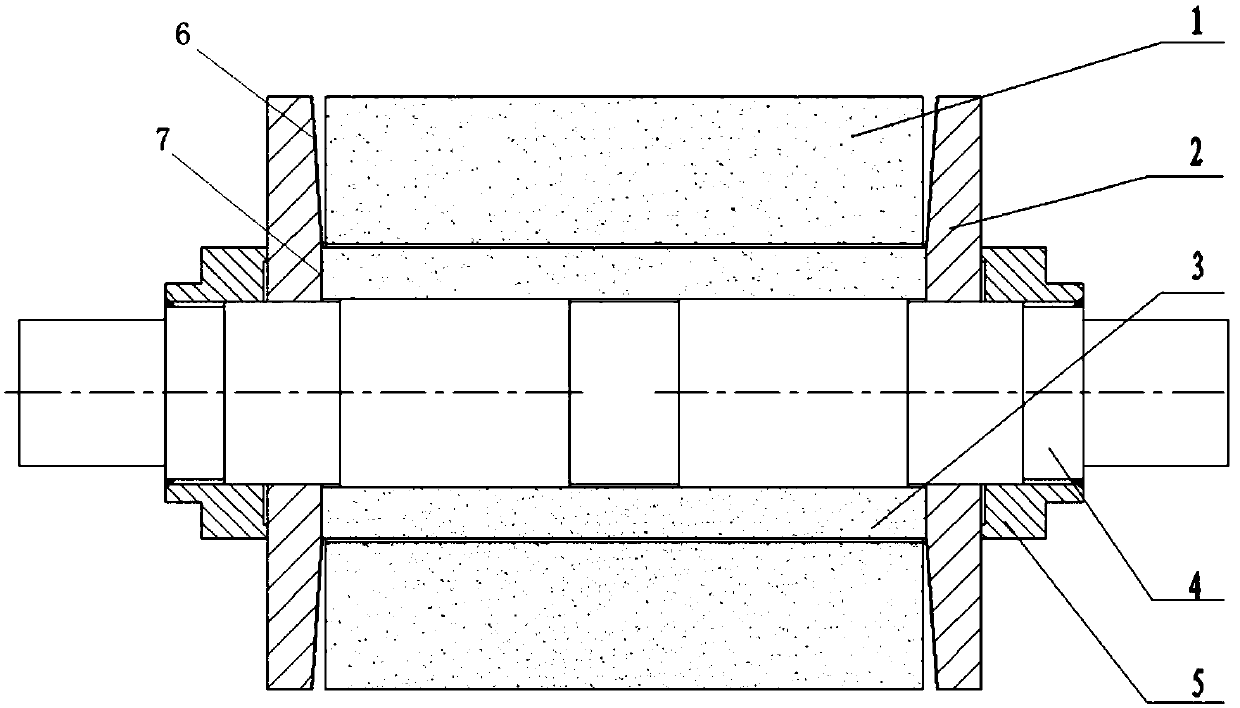

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the protection scope of the present invention cannot be limited by this embodiment.

[0029] from figure 1 It can be seen that the dynamic pressure bearing in this embodiment includes the main shaft 4, the shaft sleeve 3, the bearing rotor 1, the thrust plate 2 and the compression nut 5, the shaft sleeve 3 is set on the main shaft 4 and fixedly matched with the main shaft 4, and the bearing rotor 1 is fitted with the bushing and moves relative to each other to form a radial closed bearing. The thrust plate 2 is located on both sides of the bushing 3 and forms an axial bearing with the bearing rotor 1. The thrust plate 2 is made of structural tool steel (for example: chrome-tungsten-manganese material), the bearing rotor 1 is made of fine-grained boron carbide material, the bushing 3 is made of fine-grained boron carbide m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com