A critically meshing gear pair in unit modulus of a light-weight gear pump

A technology of meshing gears and gear pairs, which is applied in the field of unit modulus gear pairs for pumps, can solve problems such as incomprehension and acceptance, and achieve the effect of reducing stiffness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

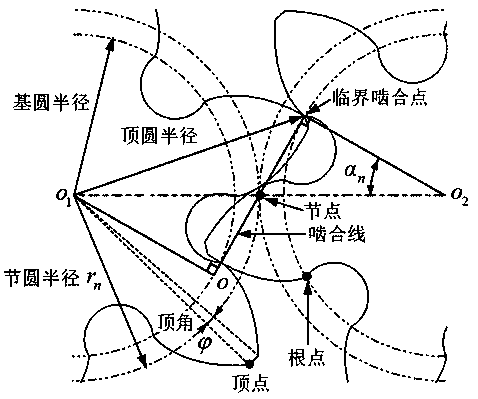

[0029] Such as figure 1 As shown, the critical meshing gear pair of a light-weight gear pump of the present invention under the unit modulus includes a pair of driving and driven involute gears with the same tooth shape parameters under the unit modulus, and the meshing position of the tooth apex is The endpoints on the meshing line are the critical points.

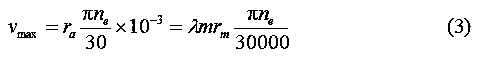

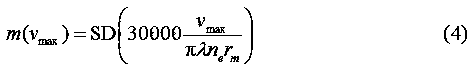

[0030] First, from the theoretical displacement formula of the gear pump, we get

[0031]

[0032] In the formula, q e is the theoretical displacement of the pump, V e is double the pitch cylinder volume of the gear pair; V q is the unit displacement volume of the pump; lambda is the shape factor of the gear, which is equal to the ratio of the radius of the tip circle to the pitch circle.

[0033] Known from formula (1), lambda directly determines the unit displacement volume of the pump V q ( lambda ), the weight of the pump is equivalent to lambda maximize.

[0034] Secondly, in figure 1 Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com