A kind of manufacturing method of carbon fiber conveying pipe for conveying concrete

A production method and technology for conveying pipelines, which are applied in pipeline protection, pipeline damage/wear prevention, and pipes, etc., can solve problems such as reduced equipment utilization, vehicle instability, and hidden safety hazards, and achieve reduced gravity load and service life. The effect of prolonging, increasing the amount of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] A carbon fiber conveying pipe used for conveying concrete, the content of carbon fiber material in its batching composition is 100%.

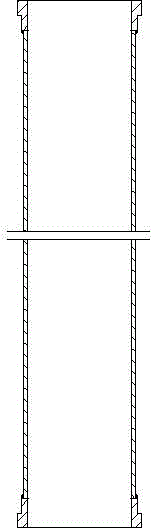

[0017] Such as figure 1 As shown, for the standard straight pipe in the carbon fiber delivery pipeline, the pipe wall thickness is more than 4mm, and the pipe wall thickness of the thickened straight pipe is more than 7mm.

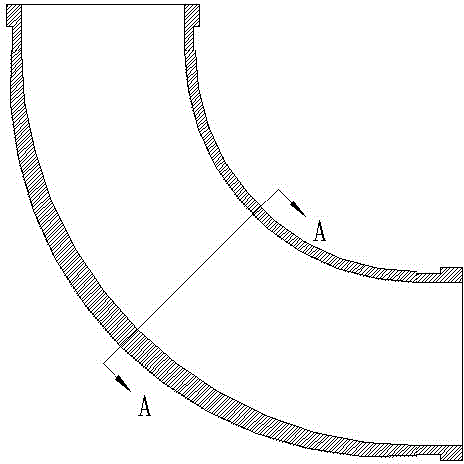

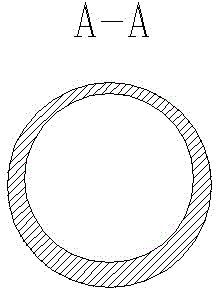

[0018] Such as figure 2 , image 3 As shown, for the elbow in the carbon fiber delivery pipeline, the thickness of the thinnest part of the pipe wall is more than 7 mm, and the thickness of the thickest part of the pipe wall is 2 to 3 times the thickness of the thinnest part of the pipe wall.

[0019] The manufacturing method of a carbon fiber delivery pipeline for transporting concrete mainly includes the following steps: S1. Oxidation treatment to obtain pre-oxidized carbon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com