MXene-based flexible polyurethane fiber membrane strain sensor

A technology of strain sensor and polyurethane fiber, which is applied in fiber processing, devices for coating liquid on the surface, textiles and papermaking, etc., can solve the problems of mutual restriction between strain sensitivity and strain sensing range, complex preparation process of flexible strain sensor, etc., to achieve Effects of increased sensitivity and strain sensing range, high sensitivity, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

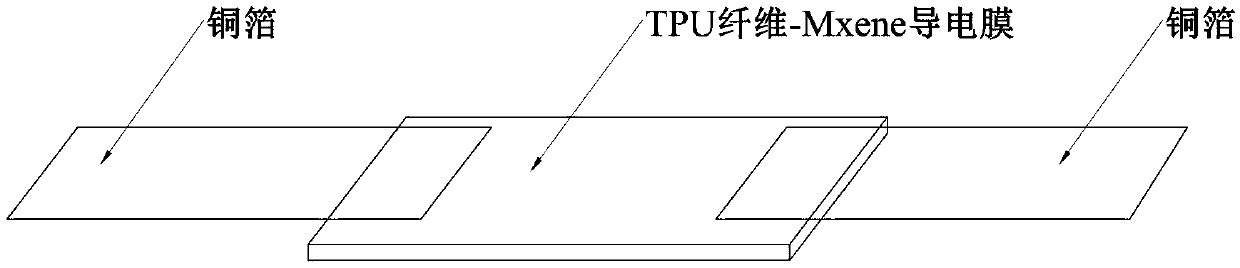

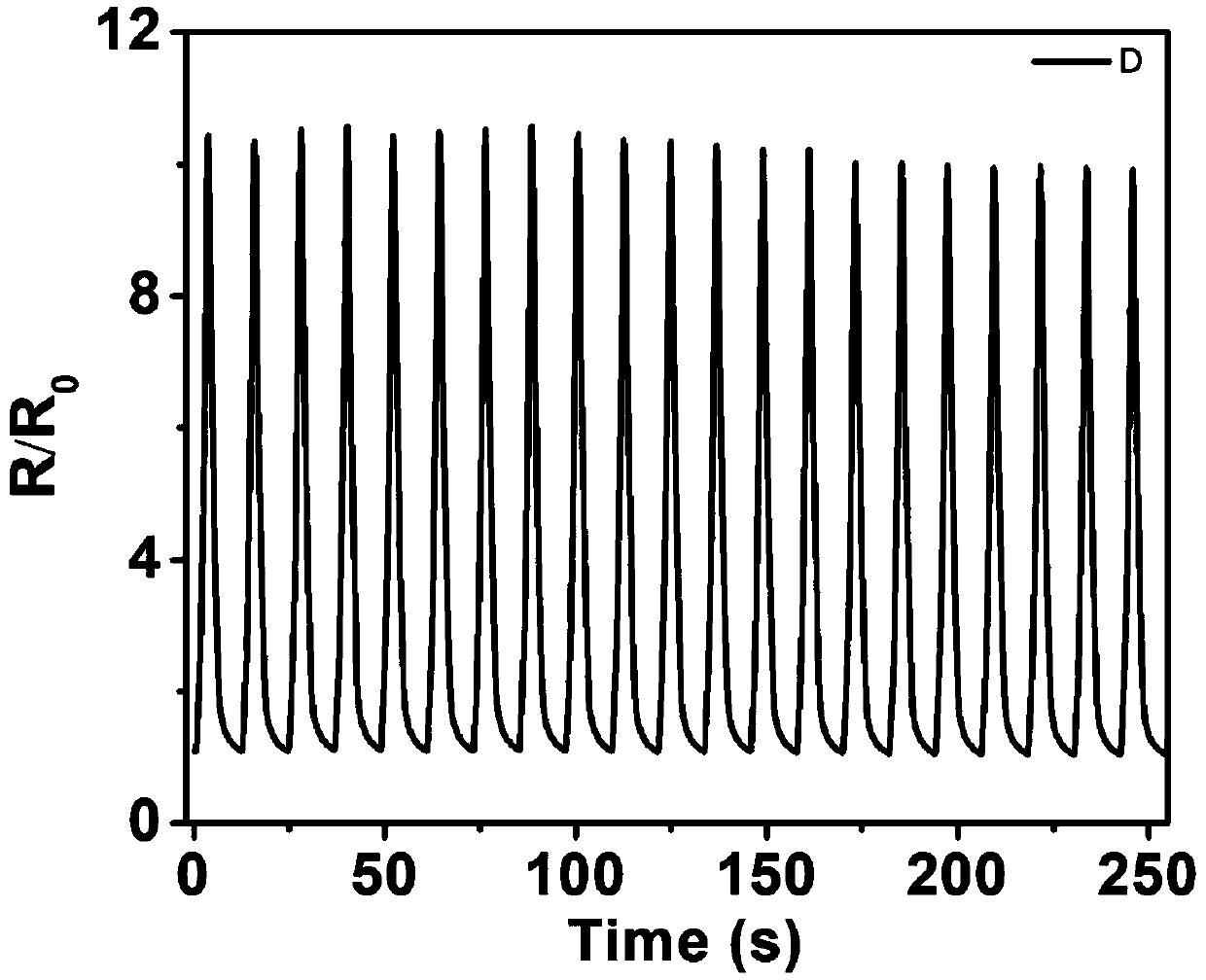

Image

Examples

Embodiment 1

[0043] (1) Preparation of MXene dispersion: Add 1.0 g of lithium fluoride (LiF) to 10 mL of hydrochloric acid with a concentration of 9 mol / L, stir for 5 min, and mix 1.0 g of Ti with a particle size of 400 mesh 3 AlC 2 The powder was added slowly, and etched at 35°C for 24h. The obtained product was centrifugally washed with deionized water at 3500 rpm until the pH was greater than 6, and the product obtained by the above centrifugal filtration was vacuum-filtered to obtain Ti 3 C 2 powder. Take 0.1g Ti 3 C 2 powder, added to 50.0ml of ethanol solution with a mass fraction of 50%, ultrasonicated in an ice-water bath for 2 hours under a nitrogen atmosphere, and the obtained solution contained Ti 3 C 2 Sheet 2mg / mL MXene dispersion (i.e. Ti 3 C 2 Dispersions).

[0044] (2) Preparation of TPU spinning solution: Add 5.9g of BASF 1180A polyurethane elastomer and 1.5g of BASF 1185A polyurethane elastomer to 40ml of DMF / THF mixed solution with a volume ratio of 1:1, stir fo...

Embodiment 2

[0049] (1) Preparation of MXene dispersion: Add 1.0 g of LiF to 10 mL of hydrochloric acid with a concentration of 9 mol / L, stir for 5 min, and mix 1.0 g of Ti with a particle size of 400 mesh 3 AlC 2 The powder was added slowly, and etched at 35°C for 24h. The obtained product was centrifugally washed with deionized water at 3500 rpm until the pH was greater than 6, and the product obtained by the above centrifugal filtration was vacuum-filtered to obtain Ti 3 C 2 powder. Take 0.05g Ti 3 C 2 powder, added to 50.0mL of 50% ethanol solution with a mass fraction of 3 C 2 Sheet 1mg / mL MXene dispersion.

[0050] (2) Preparation of TPU spinning solution: 3.7g of BASF 1185A polyurethane elastomer was added to 40ml of DMF / THF mixed solution with a volume ratio of 1:1, stirred by the rotor for 6h, and after the TPU elastomer was completely dissolved, a uniform TPU spinning solution. The mass fraction of 1185A in the solution was 10%.

[0051] (3) Preparation of TPU fiber mem...

Embodiment 3

[0055] (1) Preparation of MXene dispersion: Add 1.0 g of LiF to 10 mL of hydrochloric acid with a concentration of 9 mol / L, stir for 5 min, and mix 1.0 g of Ti with a particle size of 400 mesh 3 AlC 2 The powder was added slowly, and etched at 35°C for 24h. The obtained product was centrifugally washed with deionized water at 3500 rpm until the pH was greater than 6, and the product obtained by the above centrifugal filtration was vacuum-filtered to obtain Ti 3 C 2 powder. Take 0.15g Ti 3 C 2 powder, added to 50.0mL of 50% ethanol solution with a mass fraction of 3 C 2 Sheet 3mg / mL MXene dispersion.

[0056] (2) Preparation of TPU spinning solution: Add 4.8g of BASF 1180A polyurethane elastomer and 3.0g of BASF 1185A polyurethane elastomer to 40mL of DMF / THF mixed solution with a volume ratio of 1:1, stir for 6h through the rotor, and wait for the TPU to become elastic After the body is completely dissolved, a uniform TPU spinning solution is obtained. The mass fracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com