Improver for improving lubricity of low sulfur diesel oil and preparation method thereof

A low-sulfur diesel and improver technology, applied in the field of oil additives, can solve problems such as diesel engine corrosion, and achieve the effects of increasing the entanglement density, reducing the internal binding effect, and improving the lubricating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

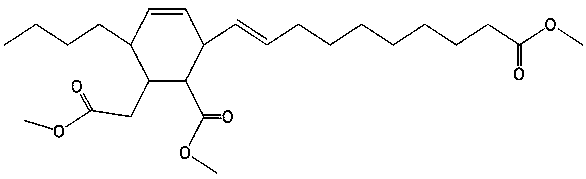

Method used

Image

Examples

Embodiment 1

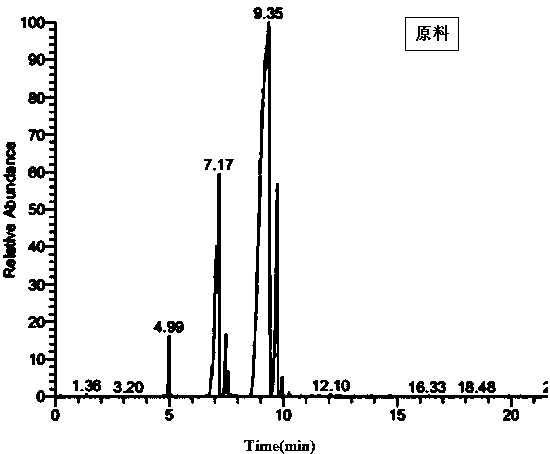

[0032] Preparation of tung oil methyl ester: Add 800g tung oil, 160g methanol, and 8g potassium hydroxide into a 2L high-pressure reactor, and carry out stirring reaction. The reaction temperature is 60°C, and the reaction time is 20min. Glycerin product 76.2g, then the upper layer product was washed 3 times with 50°C hot water, and the washed product was distilled at 2000Pa and 60°C for 2h to obtain tung oil methyl ester biodiesel.

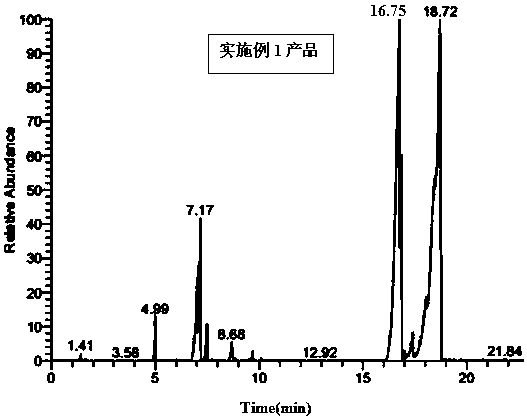

[0033] Put 270g of dimethyl glutaconate and 0.25g of hydroquinone into the reaction kettle, start stirring, and raise the temperature to 165°C for mixing. Gradually add 500 g of tung oil methyl ester biodiesel dropwise to the reaction kettle, so that the dropwise addition of tung oil methyl ester biodiesel is completed within 2 hours, and the rate of addition is basically uniform. After removing the unreacted dimethyl glutaconate and tung oil methyl ester under reduced pressure at ℃ for 2 h, the improver product A was obtained, and the reaction m...

Embodiment 2

[0037] The preparation process and operating conditions were the same as in Example 1, except that the addition of tung oil methyl ester biodiesel was completed dropwise within 1 hour, and the reaction was continued at 240°C for 3 hours after the drop was completed to obtain improver product B, with a reaction molecular conversion rate of 80.4%. After testing, the acid value of the product is 1.6mgKOH / g, the freezing point is -25.2°C, and the water layer is not turbid in the demulsibility test.

Embodiment 3

[0039] The preparation process and operating conditions were the same as in Example 1, except that the addition of tung oil methyl ester biodiesel was completed dropwise within 3 hours, and the reaction was continued at 200°C for 5 hours after the drop was completed to obtain improver product C with a reaction molecular conversion rate of 81.5%. The acid value of the product is 1.4mgKOH / g, the freezing point is -28.8°C, and the water layer is not turbid in the demulsibility test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com