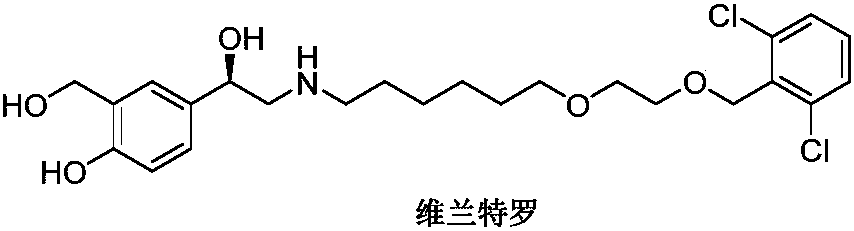

Method for preparing Vilanterol

A technology of tetrahydrofuran and reaction solvent, which is applied in the field of preparation of vilanterol, can solve the problems of difficulty in meeting the quality requirements of chiral purity, difficulty in constructing chiral centers, and restrictions on industrial applications, so as to avoid the use of protective groups and increase the utilization of atoms The effect of low production rate and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

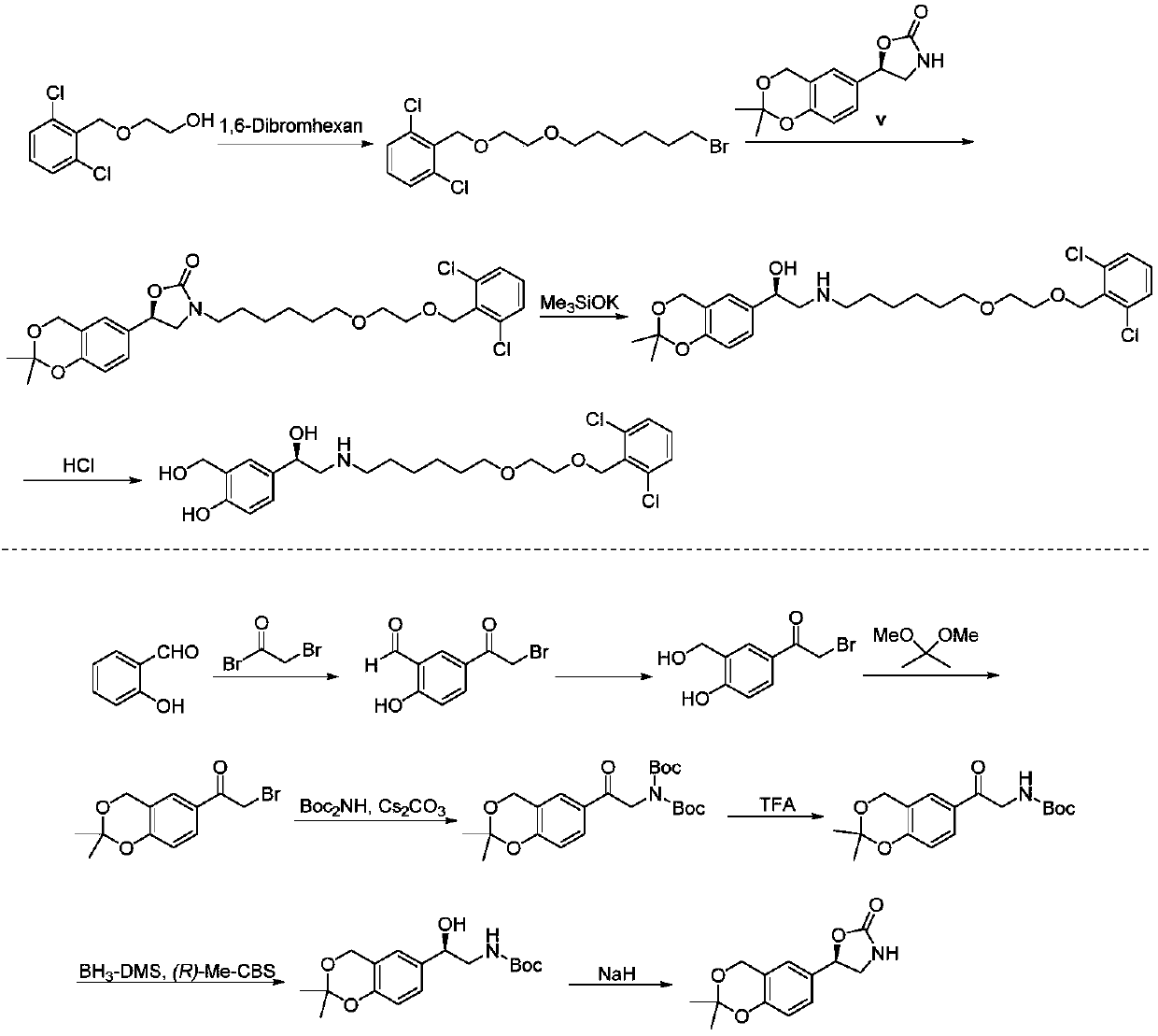

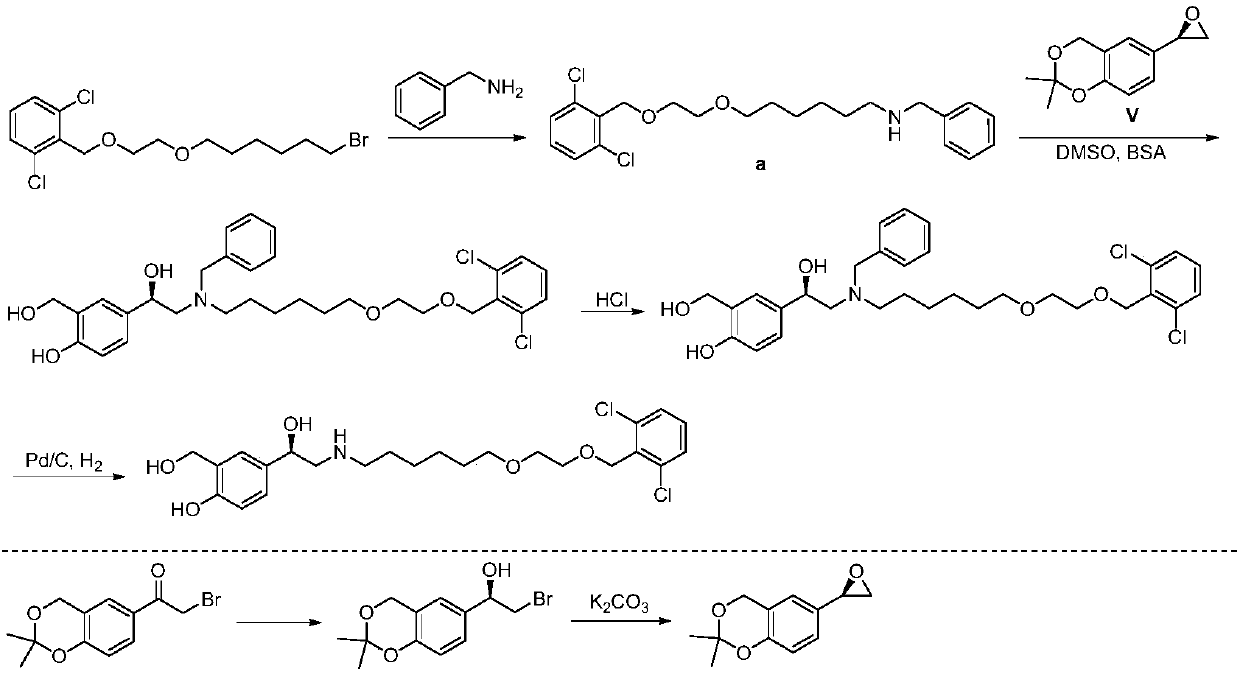

Method used

Image

Examples

Embodiment 1

[0023] Preparation of Intermediate 1:

[0024] Add 200mL water to a 500mL three-necked flask, add 13.2g (1.1eq) sodium hydroxide in batches, cool to 0-5°C, add 37.2g (1eq) salicyl alcohol while stirring, and then add 0.68g (1%) Benzyltriethylammonium chloride, fully stirred for 1 hour, under the condition of 0-5 ℃, slowly added 44.4g of 50% glyoxylic acid aqueous solution into the reaction system dropwise within 1 hour, and the temperature of the reaction system rose to 25 ℃, continue to react for 6 hours, and the remaining raw materials in the liquid phase are less than 1%, and the reaction is completed. Cool the system to 0-5°C, adjust the pH to 2-3 with concentrated hydrochloric acid, extract with 100×2 mL of tert-butyl acetate, combine the organic phases, wash with 100 mL of saturated saline and 100 mL of water, dry over anhydrous magnesium sulfate, and filter. Concentration gave a white solid, and the crude product was recrystallized from toluene to obtain 50 g, with a y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com