Ultrasound-assisted superfine ERI type molecular sieve rapidly synthesizing method

An ultrasonic-assisted, molecular sieve technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of shortened synthesis time, reduced synthesis cost, and long preparation time, achieving shortened synthesis time, reduced synthesis cost, and homogeneous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

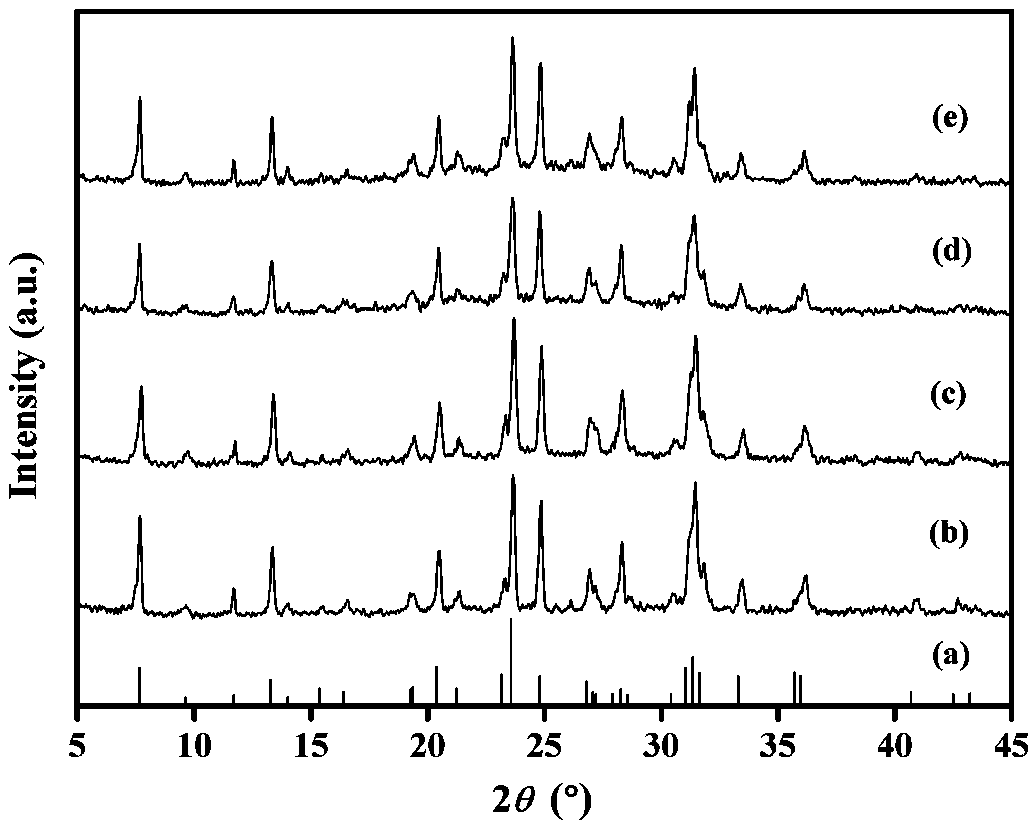

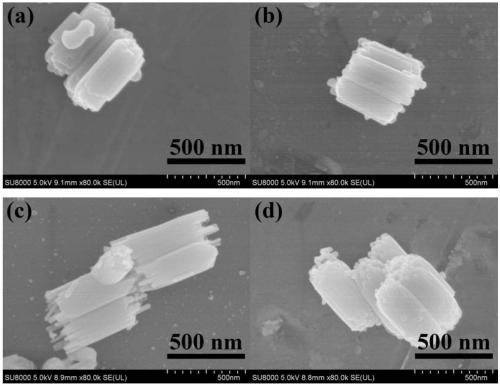

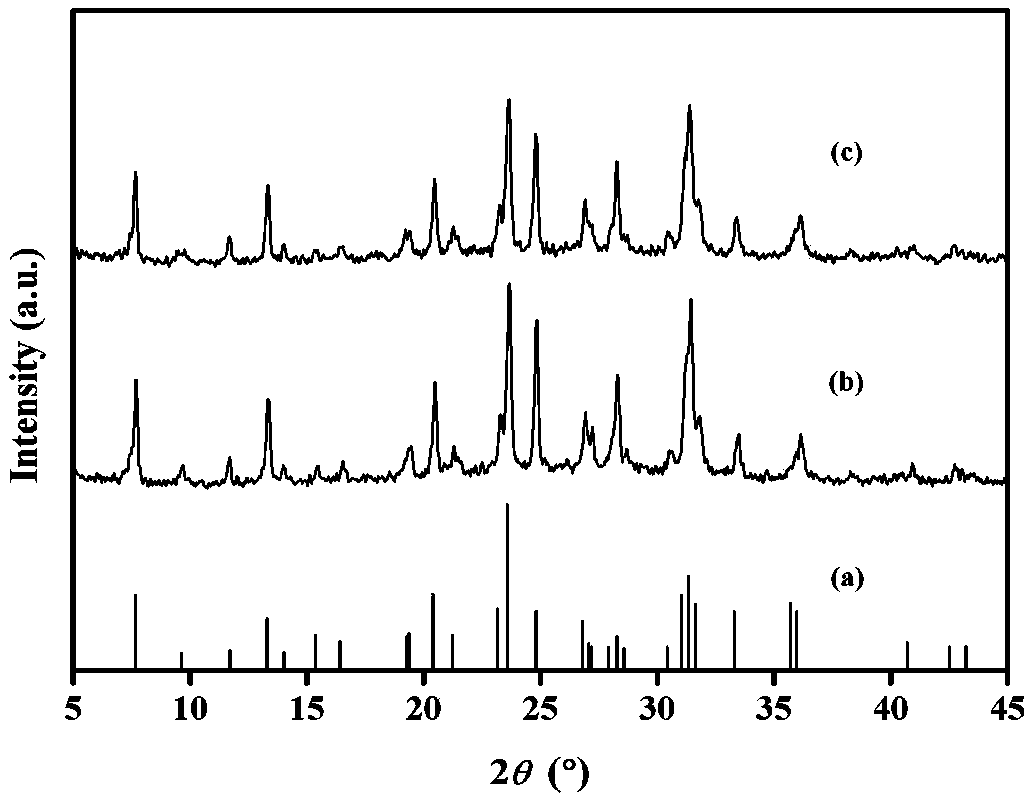

Method used

Image

Examples

Embodiment 1

[0039] Add TEAOH and Al[OCH(CH 3 )C 2 h 5 ] 3 , stir at room temperature until clarified, then add silicon source, then add KOH, C 12 h 3 OBr 2 N 2 , the molar ratio of each component oxide form is: n(SiO 2 ):n(Al 2 o 3 ):n(TEAOH):n(KOH):n(C 12 h 3 OBr 2 N 2 ):n(H 2 (0)=1:0.03:0.09:0.8:0.13:25 made erionite crystal seed, reaction temperature is under 150 ℃ of conditions, reacted for 5 days, the solid-liquid phase has obvious delamination after the reaction, separates the lower layer solid phase, will The solid phase was boiled, centrifuged, washed with deionized water until neutral, dried at 100°C for 12 hours, and then transferred to a muffle furnace for calcination at 550°C for 12 hours to obtain erionite seed crystals.

[0040] After dissolving aluminum hydroxide, sodium hydroxide and potassium hydroxide in sequence, after the mixed solution is clarified, add water to dilute and add silicon source. The ratio (molar ratio) of each component oxide form is: n(SiO...

Embodiment 2

[0044] Add TEAOH and Al[OCH(CH 3 )C 2 h 5 ] 3 , stir at room temperature until clarified, then add silicon source, then add KOH, C 12 h 3 OBr 2 N 2 , the molar ratio of each component oxide form is: n(SiO 2 ):n(Al 2 o 3 ):n(TEAOH):n(KOH):n(C 12 h 3 OBr 2 N 2 ):n(H 2 O)=1:0.03:0.09:0.8:0.13:25 to make erionite seed crystals, the reaction temperature is 130-180°C, react for 3-7 days, after the reaction, the solid-liquid phase has obvious stratification, and the lower layer is separated For the solid phase, boil the solid phase, centrifuge it, wash it with deionized water until neutral, dry it at 70-120°C for 5-15h, transfer it to a muffle furnace for calcination at 400-600°C for 5-15h to obtain a seed crystal.

[0045] After dissolving aluminum hydroxide, sodium hydroxide and potassium hydroxide in sequence, after the mixed solution is clarified, add water to dilute and add silicon source. The ratio (molar ratio) of each component oxide form is: n(SiO 2 ):n(Al 2 ...

Embodiment 3

[0049] Add TEAOH and Al[OCH(CH 3 )C 2 h 5 ] 3 , stir at room temperature until clarified, then add silicon source, then add KOH, C 12 h 3 OBr 2 N 2 , the molar ratio of each component oxide form is: n(SiO 2 ):n(Al 2 o 3 ):n(TEAOH):n(KOH):n(C 12 h 3 OBr 2 N 2 ):n(H 2 O)=1:0.03:0.09:0.8:0.13:25 to make erionite seed crystals.

[0050] After dissolving aluminum hydroxide, sodium hydroxide and potassium hydroxide in sequence, after the mixed solution is clarified, add water to dilute and add silicon source. The ratio (molar ratio) of each component oxide form is: n(SiO 2 ):n(Al 2 o 3 ):n(Na 2 O):n(K 2 O):n(H 2(0)=1:0.020:0.26:0.09:200, sonicated at room temperature for 60 minutes to obtain a synthetic sol. Add 0.3wt% of the prepared erionite seed crystals to the synthetic sol, the reaction temperature is 160°C, the reaction time is 24h, the solid-liquid phase of the reactant is clearly separated, the lower solid phase obtained is boiled and washed with deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com