Metal membrane storage tank and processing method of metal membrane

A processing method and diaphragm technology are applied in the processing field of metal diaphragm storage tanks and their metal diaphragms, which can solve the problems of potential safety hazards, easy shaking of propellants, inconvenience for long-term storage, etc., and achieve high stability and safety, and easy assembly. , The effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

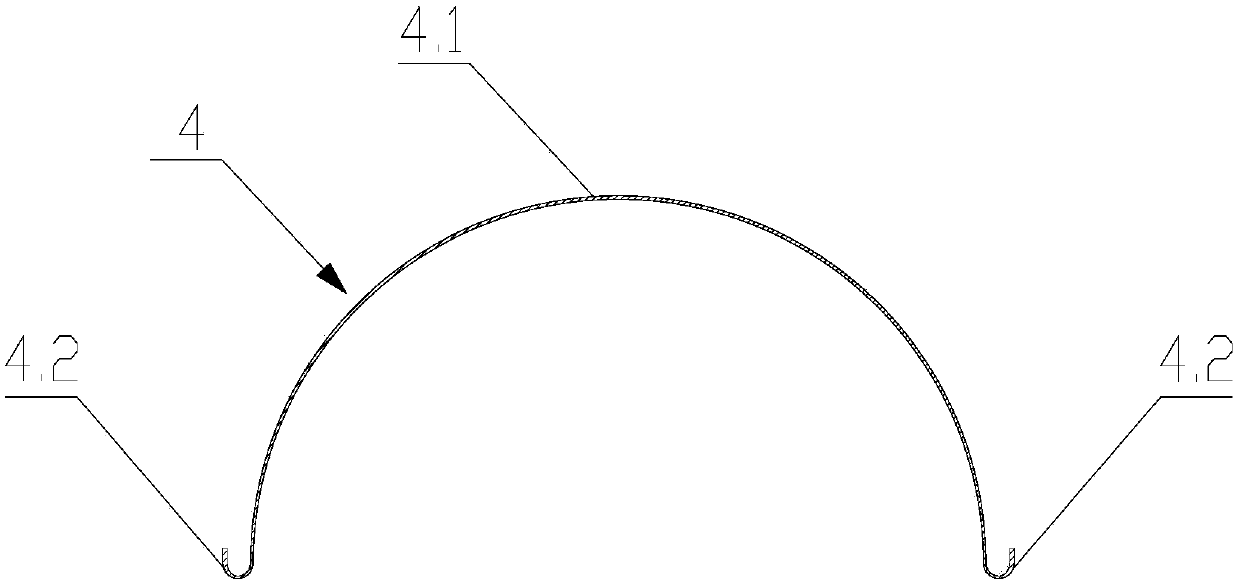

[0047] The processing method of metal diaphragm of the present invention, comprises the steps:

[0048] 1) Material selection:

[0049] Conduct tensile test and component inspection on the unheated thick sheet, select the thick sheet that meets the design requirements, the elastic modulus of the selected thick sheet is E=69GPa, Poisson’s ratio μ=0.33, and the tensile strength is 76MPa , the yield strength is 28MPa, and the elongation is 39%. In this way, the metal diaphragm material chooses a thick sheet with a relatively small yield limit and good ductility, so as to ensure the weldability with the upper shell.

[0050] 2) Spinning:

[0051] The thick sheet material selected in step 1) is subjected to spinning processing to obtain a diaphragm blank of the required shape. The spinning processing includes hemispherical arc surface spinning processing and U-shaped arc surface spinning processing, wherein the top tight film 13, hemispherical Shaped mandrel 14 and U-shaped mandr...

Embodiment 2

[0059] The processing method of metal diaphragm of the present invention, comprises the steps:

[0060] 1) Material selection:

[0061] Conduct tensile test and component inspection on the unheated thick sheet, select the thick sheet that meets the design requirements, the elastic modulus E=82GPa, Poisson’s ratio μ=0.35, and the tensile strength of the selected thick sheet is 88MPa , Yield strength is 38MPa, elongation is 45%;

[0062] 2) Spinning:

[0063] The thick sheet material selected in step 1) is subjected to spinning processing to obtain a diaphragm blank of the desired shape. The spinning processing includes hemispherical arc surface spinning processing and U-shaped arc surface spinning processing, wherein the top tight film 13, hemispherical Shaped mandrel 14 and U-shaped mandrel 15 are designed and processed according to the shape of the metal diaphragm;

[0064] In the described hemispherical curved surface spinning process, the angle a=0° between the rotary wh...

Embodiment 3

[0071] The processing method of metal diaphragm of the present invention, comprises the steps:

[0072] 1) Material selection:

[0073] Conduct tensile test and component inspection on the thick sheet that has not been heat-treated, and select the thick sheet that meets the design requirements. The elastic modulus of the selected thick sheet is E=75GPa, Poisson’s ratio μ=0.34, and the tensile strength is 80MPa , the yield strength is 32MPa, and the elongation is 42%;

[0074] 2) Spinning:

[0075] The thick sheet material selected in step 1) is subjected to spinning processing to obtain a diaphragm blank of the desired shape. The spinning processing includes hemispherical arc surface spinning processing and U-shaped arc surface spinning processing, wherein the top tight film 13, hemispherical Shaped mandrel 14 and U-shaped mandrel 15 are designed and processed according to the shape of the metal diaphragm;

[0076] like Figure 4 As shown, in the described hemispherical ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com