Automobile anti-lock failure remedy switch

An anti-lock and anti-lock braking technology, applied in the field of automobile brake devices, can solve problems such as failure of the anti-lock braking system, and achieve the effects of avoiding wheel locking, increasing service life and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

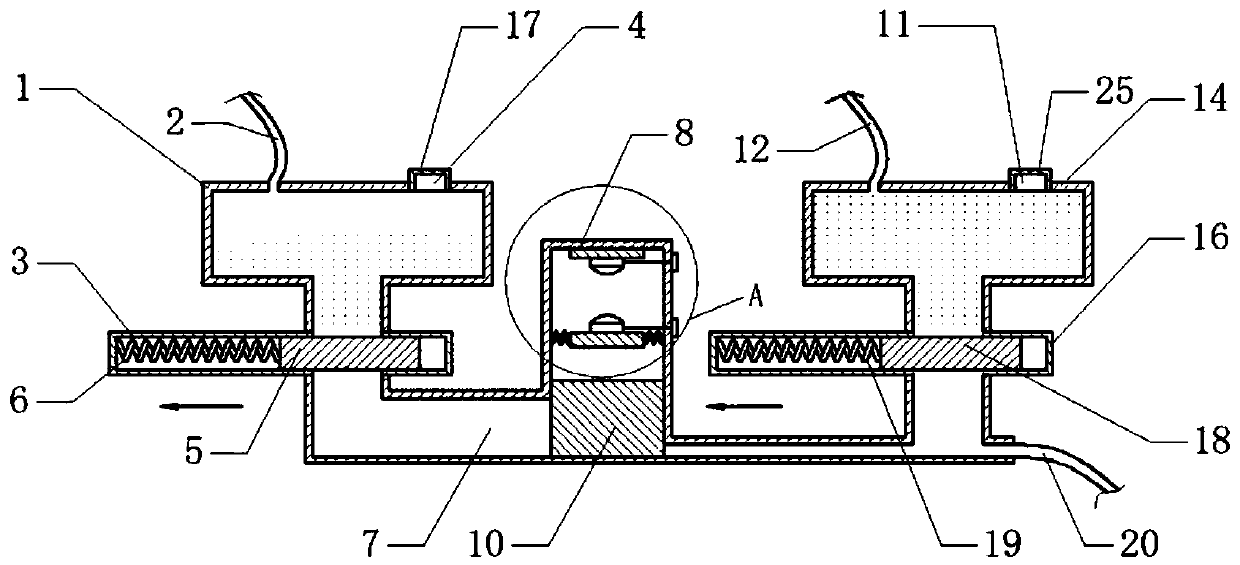

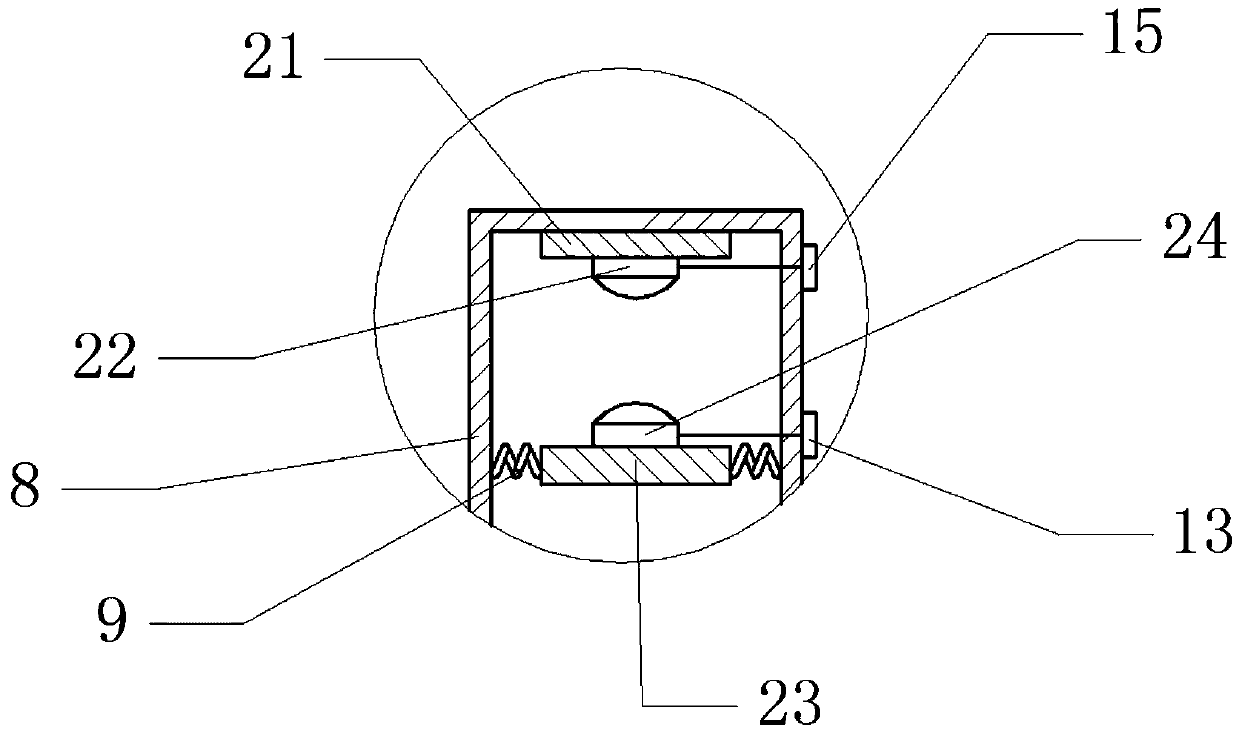

[0022] Embodiment one is basically as attached figure 1 And attached figure 2 As shown, the automobile anti-lock brake failure remedial switch includes the anti-lock brake system installed in the car, the first water outlet mechanism, the switch contact device, the second water outlet mechanism, the first water collection tank and the second water collection tank for collecting rainwater The first water outlet mechanism includes a first water storage tank 1 installed on the car. The first water storage tank 1 communicates with a first water collection pipe 2 whose upper opening is located in the first water collection tank. The top of the first water storage tank 1 is provided with a first The first water inlet 4 and the first water inlet 4 are threadedly connected with the first water filling cap 17, the bottom of the first water storage tank 1 is connected with the pipeline 7, and the first chute 3 is arranged in the pipeline 7, and the sliding connection in the first chute...

Embodiment 2

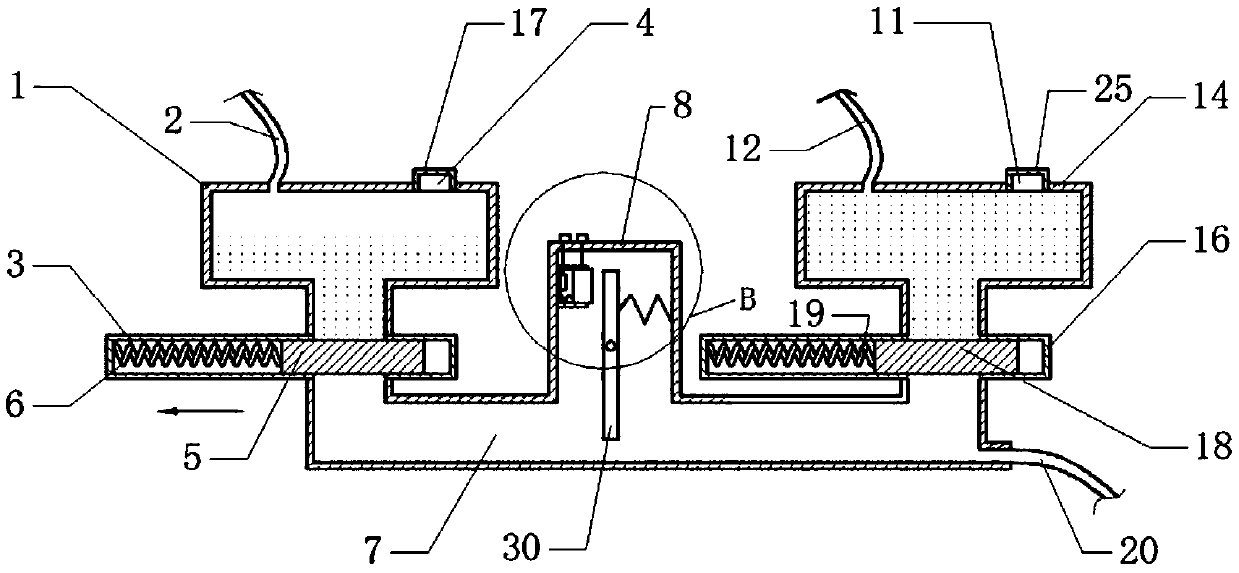

[0027] Embodiment two as attached image 3 And attached Figure 4 As shown, the difference from Embodiment 1 is that the switch contact device includes a box body 8, the box body 8 communicates with the pipeline 7, the pipeline 7 is connected with a water outlet pipe 20, and the outlet of the water outlet pipe 20 is located above the brake disc, and the side of the box body 8 The wall is fixedly connected with a cylinder 26, the bottom of the cylinder 26 is fixedly connected with a conductive static contact block 27, and the inside of the cylinder 26 is slidably connected with a conductive dynamic contact block 28, and the dynamic contact block 28 and the cylinder 26 A third spring 29 is fixedly connected between them, and a lever 30 is provided on one side of the opening of the cylinder 26. The middle part of the lever 30 is hinged with the box body 8, and a fourth spring 31 is fixedly connected between the lever 30 and the box body 8, and the box body The outer wall of 8 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com