Semi-automatic butt joint machine for manufacturing three-way pipeline

A semi-automatic, docking machine technology, applied in the direction of manufacturing tools, applications, household appliances, etc., can solve problems affecting installation, flange installation deviation, waste of manpower and time, etc., to ensure accuracy, stability, and avoid unnecessary The effect of the deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

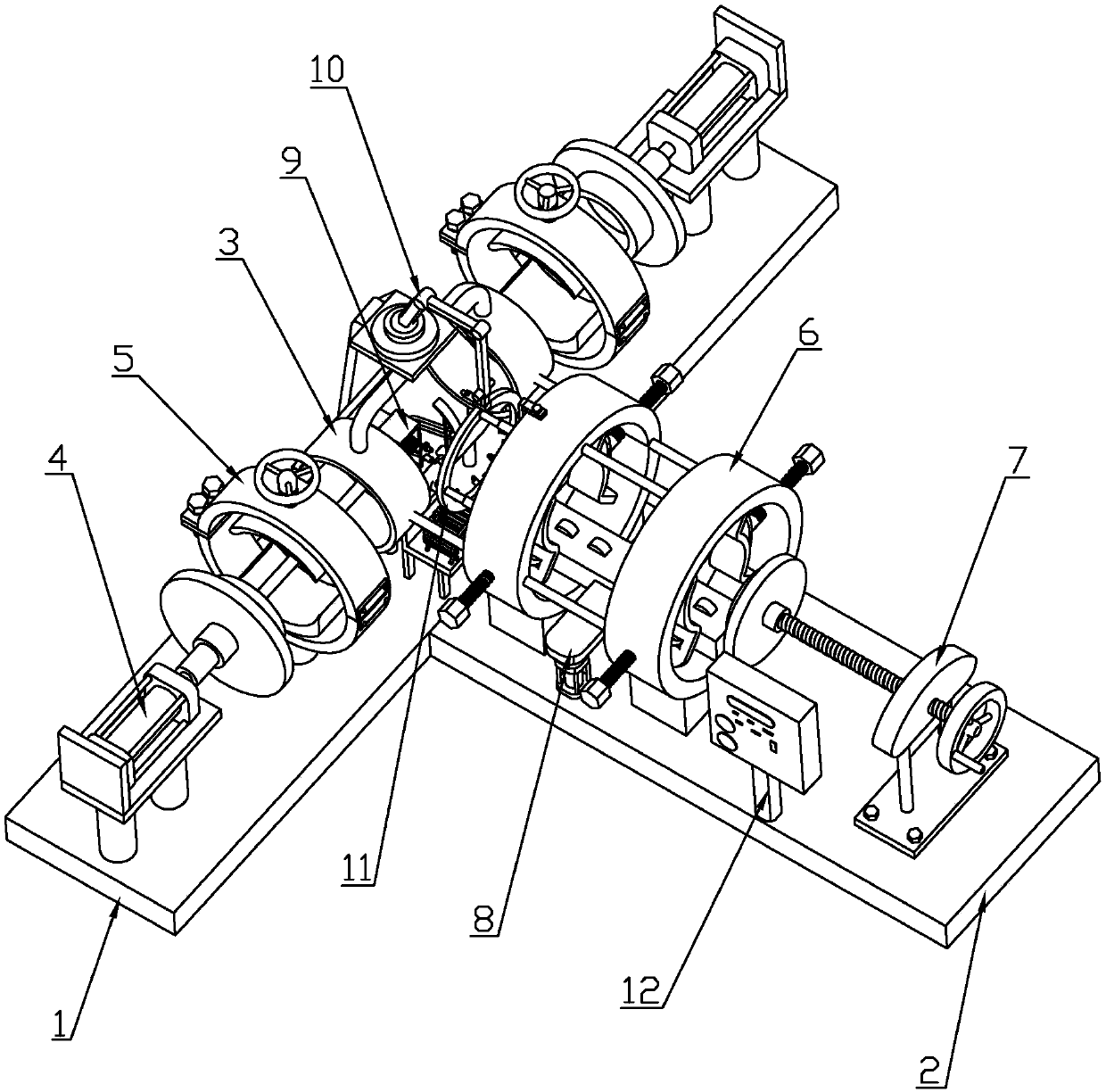

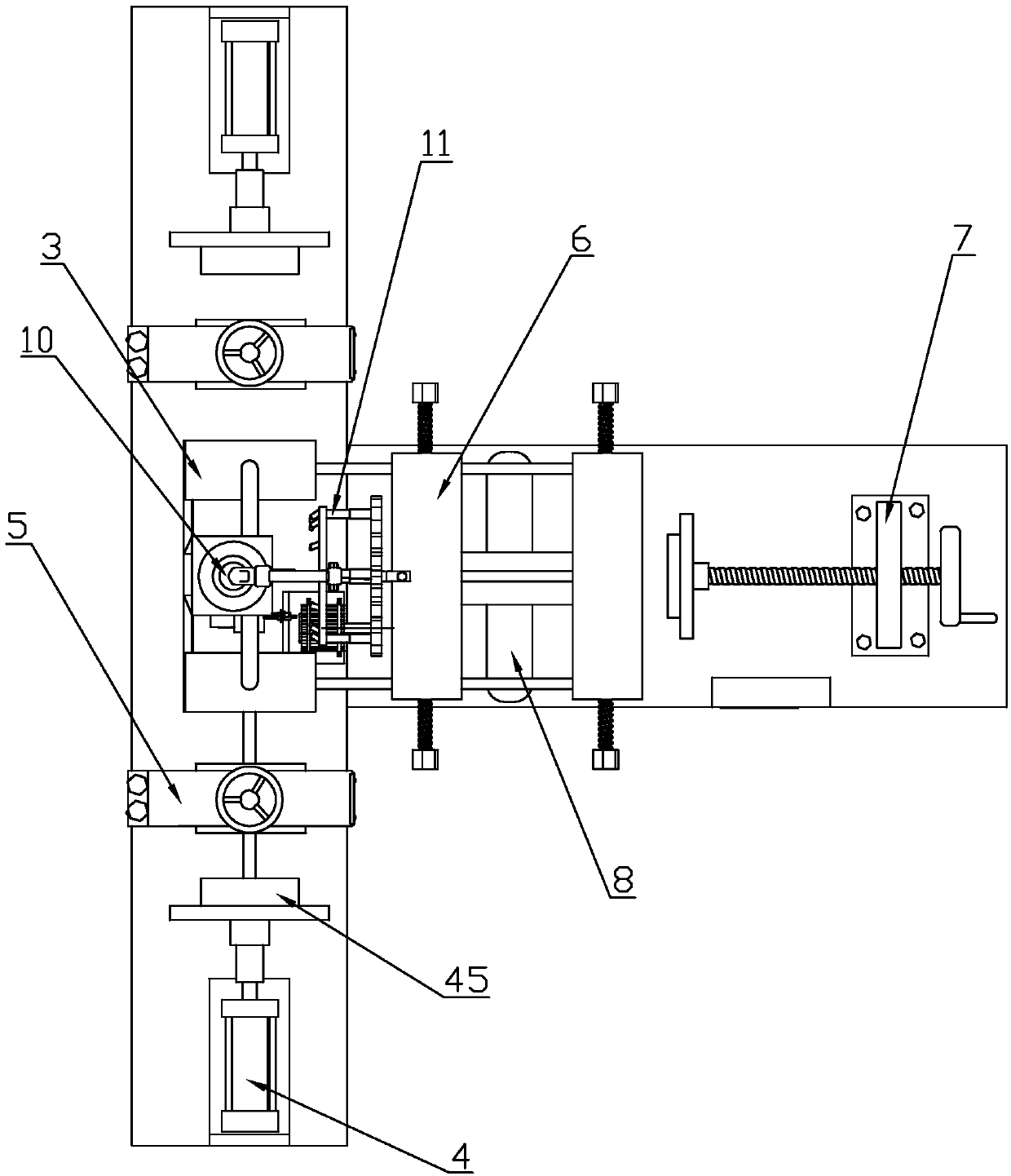

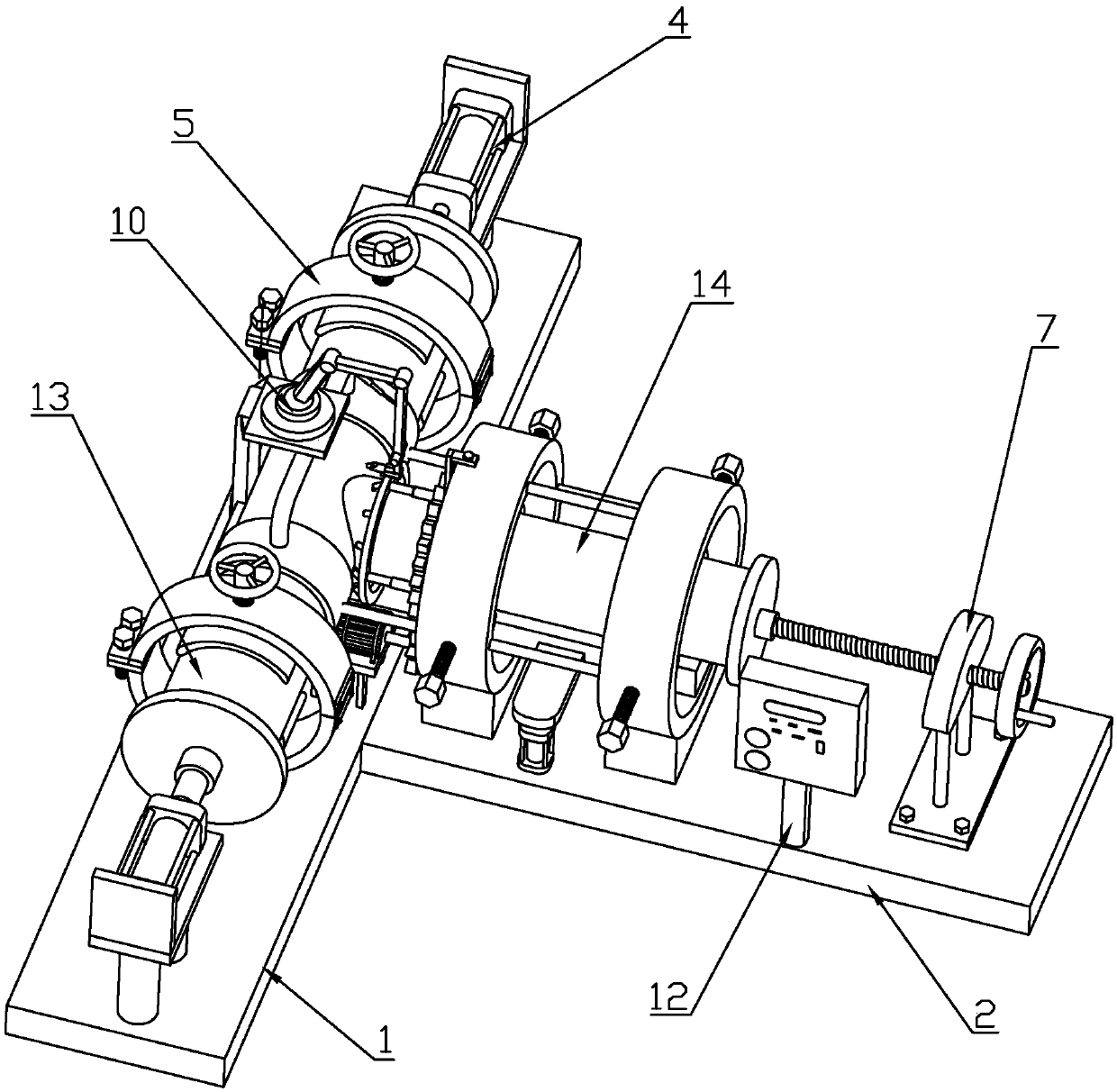

[0035] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-13 , to further specifically describe the technical solution of the present invention.

[0036] refer to Figure 1 to Figure 3 As shown, a semi-automatic docking machine for manufacturing three-way pipes, including a vertical plate seat 1, a horizontal plate seat 2, an interface fixing frame 3, a pushing mechanism 4, a clamping mechanism 5, a binding collar 6, and a manual docking mechanism 7 , conveying mechanism 8, internal repairing welding device 9, cutter 10, external repairing welding device 11, the vertical plate seat 1 side is provided with the horizontal plate seat 2 that is vertically arranged with it, wherein the two pipes that need to be docked are respectively The vertical tube 13 and the horizontal tube 14, the vertical tube 13 is set on the side of the vertical plate seat 1, the horizontal tube 14 is set on the side of the horizontal pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com