Fluid forming method of sheet metal part for gas turbine exhaust channel supporting wall

A gas turbine and supporting wall technology, applied in the field of sheet metal forming, can solve the problems of poor product forming process, difficult forming, and less material thinning, so as to reduce one-time processing investment, ensure wall thickness reduction, and reduce splicing welding seam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Processing little endian 1050, big endian 1600, height 359, ellipse-shaped curved body with outer ribs

[0047] The processing flow chart is attached Figure 4 shown.

[0048] (1) Equipment and parameter selection

[0049] According to the envelope size of the outer contour of the structural parts, a 400T pressure forming machine is selected, and high-pressure water is selected as the fluid medium.

[0050] (2) Design of forming blank

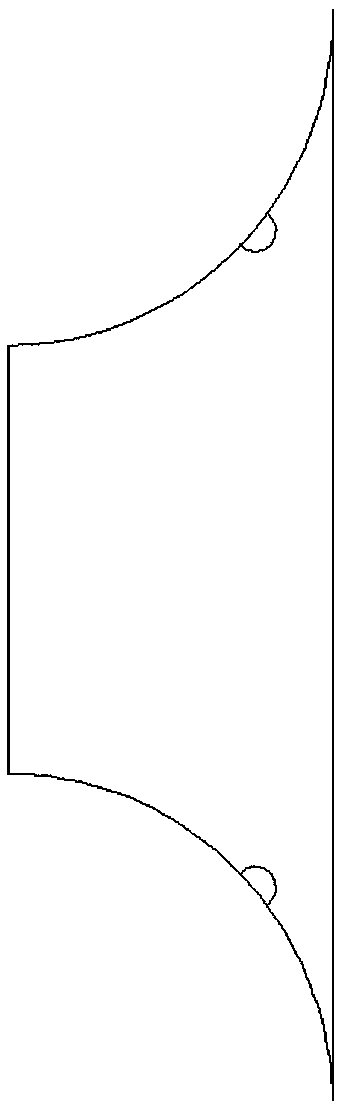

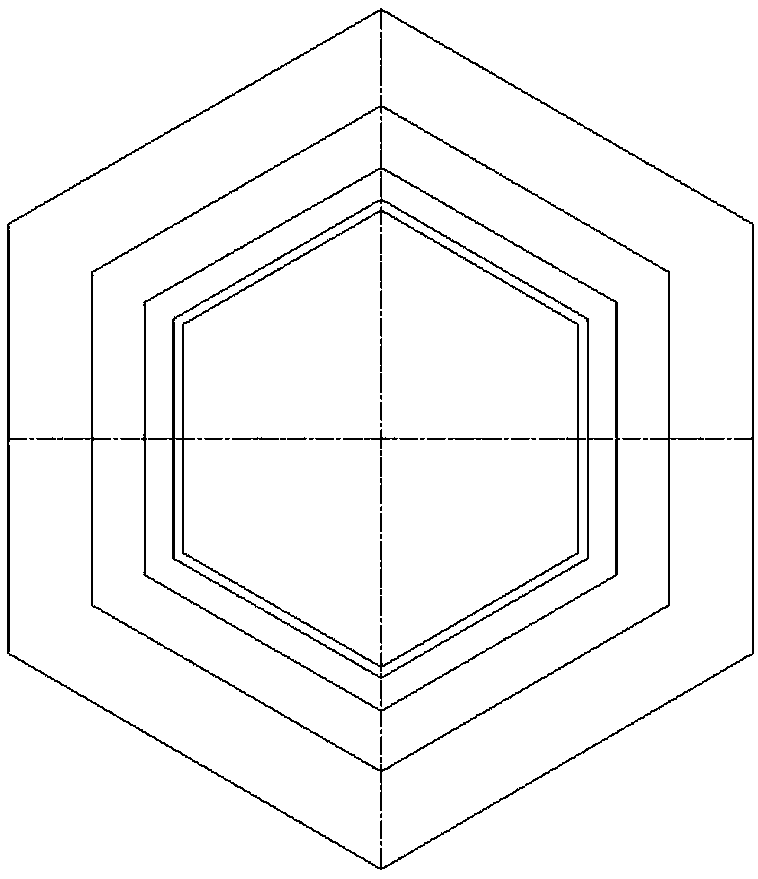

[0051] According to the expansion diagram of the formed parts, design the splicing form of the blank. Tailor-welded three-layer nested plates are taken, preformed to the cone. The splicing method of blanks and the top view of splicing are as follows: figure 2 shown. At the same time, the splicing weld of the rough blank is polished to prevent stress concentration points during the forming process.

[0052] (3), fluid forming tooling processing

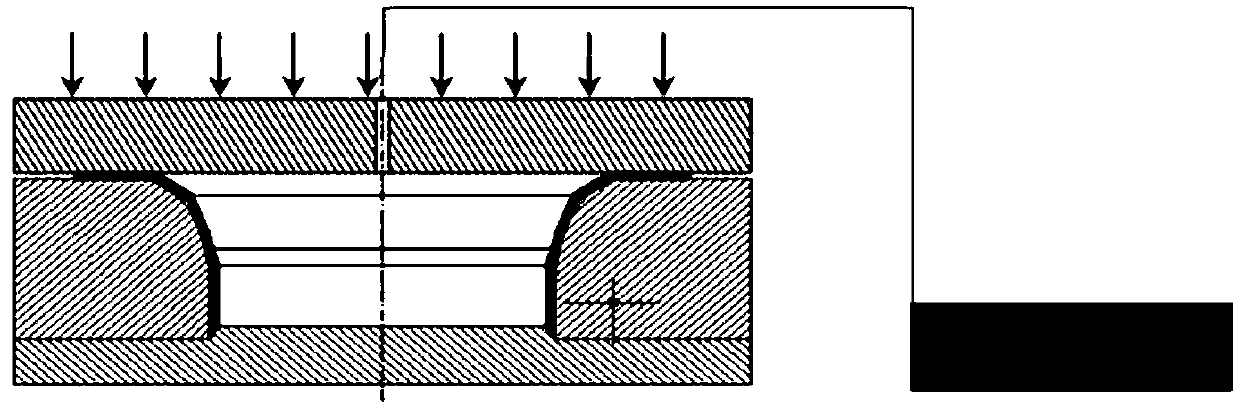

[0053] Such as image 3As shown, the forming die is processed according to the ...

Embodiment 2

[0061] Processing little endian 608: big endian 1540, height 442, ellipsoidal curved body with internal ribs

[0062] Processing flow chart such as Figure 4 shown.

[0063] (1) Equipment and parameter selection

[0064] As in Example 1.

[0065] (2) Design of forming blank

[0066] As in Example 1.

[0067] (3) Fluid forming tooling processing

[0068] Such as image 3 As shown, the forming die is processed according to the actual size of the product, and the ribs are processed in the forming die according to the product pattern, so that the inner rib protrusions can be formed while the fluid is bulging. Bottom plate, pressure plate and other auxiliary devices are processed in the same proportion as the product structure size, and the thickness is 50-80mm.

[0069] All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com