Preparation method of lithium ion battery sizing agent

A lithium-ion battery and slurry technology, which is applied in the field of lithium-ion battery slurry preparation, can solve the problems that the glue is easy to adhere to the pipe wall, difficult to clean, and the pipeline is not smooth, so as to improve the utilization rate of equipment and The effects of increasing production capacity, shortening process time, and improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

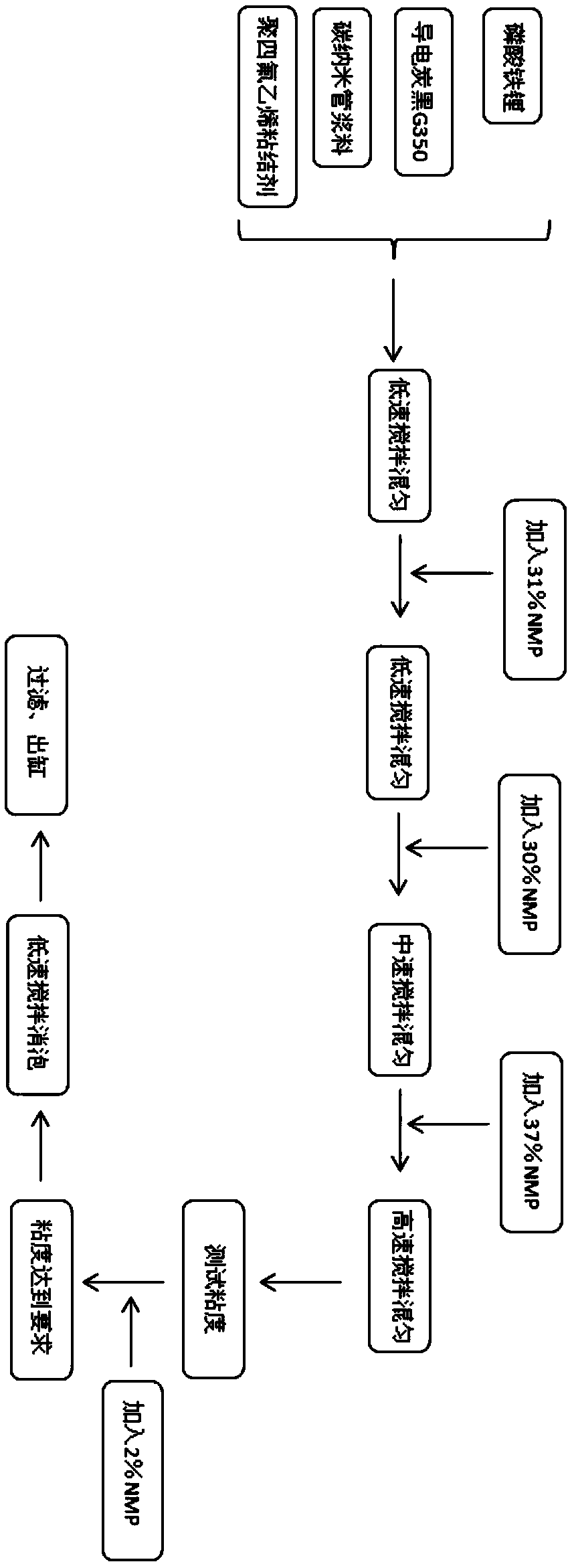

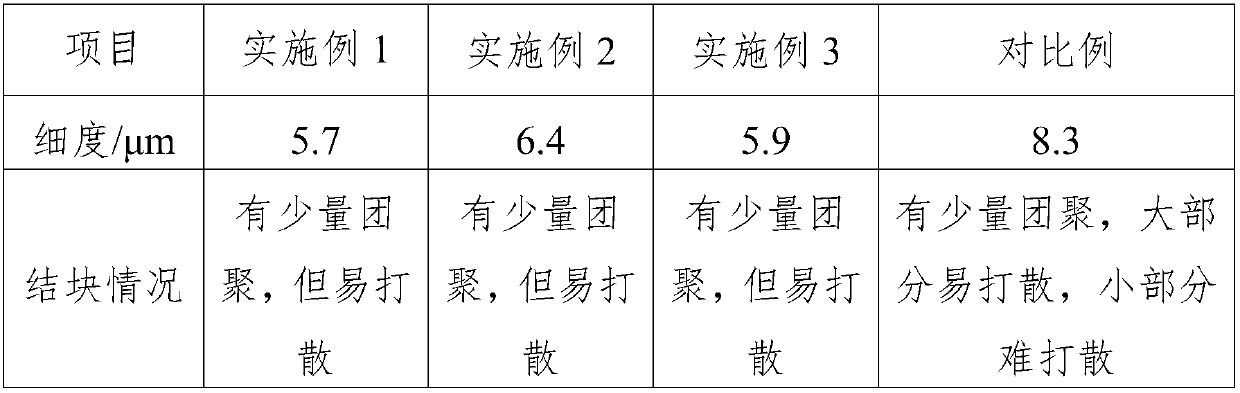

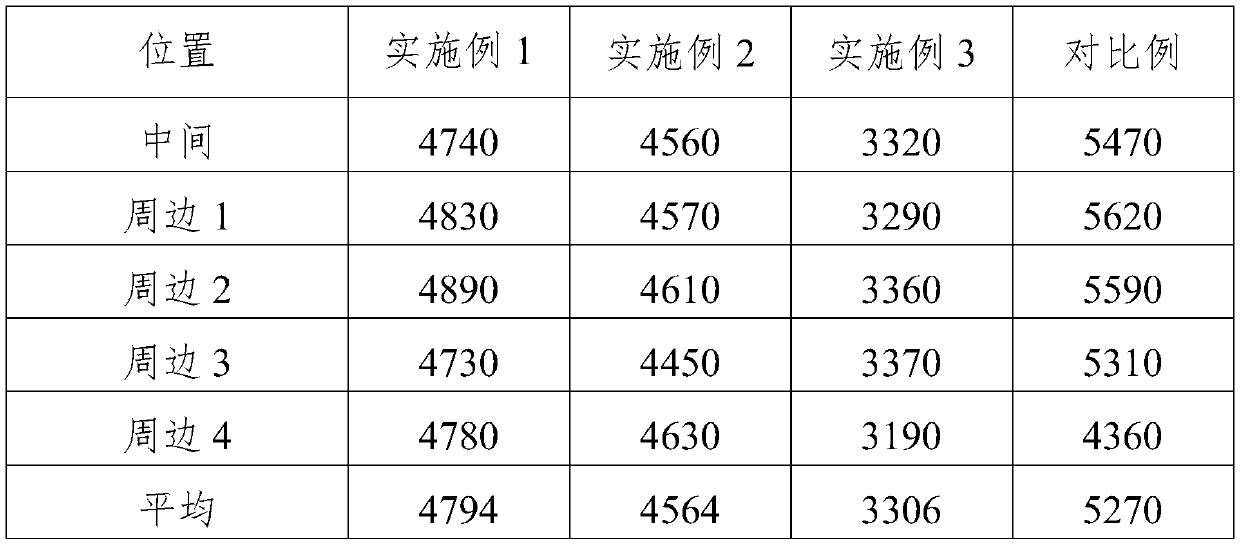

[0042] according to figure 1 The steps shown prepare an oily positive electrode slurry for a lithium ion battery.

[0043] Dry material mixing: according to the formula: 94 parts of lithium iron phosphate powder, 2 parts of conductive carbon black 350G, 5 parts of carbon nanotube conductive paste, 3 parts of polytetrafluoroethylene binder and 100 parts of NMP, and accurately weigh each raw material Ingredients, 94 parts of lithium iron phosphate powder, 2 parts of conductive carbon black 350G, 5 parts of carbon nanotube conductive paste and 3 parts of polytetrafluoroethylene binder are added to the mixing tank with stirring and dispersion, at 6rpm Low speed mixing was carried out at stirring speed for 90 minutes.

[0044] Low-speed high-viscosity stirring: Add 31 parts of NMP, and mix at a low speed of 7 rpm and 20 rpm for 90 minutes to make the material in the mixing tank into a lump, and make the material on the tank wall and the stirring paddle every 30 minutes. Dry mater...

Embodiment 2

[0050] Preparation of lithium ion battery oily negative electrode slurry.

[0051] Dry material mixing: according to the formula: 95 parts of intermediate carbon microspheres, 2.6 parts of conductive carbon black KS-6, 0.2 parts of oxalic acid, 3.8 parts of polytetrafluoroethylene binder and 101 parts of NMP, accurately weigh the ingredients of each raw material, and put Add 95 parts of intermediate carbon microspheres, 2.6 parts of conductive carbon black KS-6, 0.2 parts of oxalic acid and 3.8 parts of polytetrafluoroethylene binder into the mixing tank with stirring and dispersion, and carry out low-speed stirring at a stirring speed of 7rpm Mix for 80 minutes.

[0052] Low-speed high-viscosity stirring: Add 28 parts of NMP, and mix at a low speed of 6 rpm and a dispersion speed of 30 rpm for 100 minutes to make the material in the mixing tank into a lump, and every 30 minutes. Dry material to clean up.

[0053] Medium-speed medium-viscosity stirring: continue to add 35 pa...

Embodiment 3

[0058] Preparation of aqueous negative electrode slurry for lithium ion batteries.

[0059] Dry material mixing: According to the formula: 96 parts of nano-carbon spheres, 2.6 parts of SFG-15 conductive agent, 2.1 parts of CMC powder, 81 parts of deionized water and 8 parts of styrene-butadiene emulsion with a weight concentration of 45%, and accurately weigh each raw material Ingredients, 96 parts of carbon nanospheres, 2.6 parts of SFG-15 conductive agent, and 2.1 parts of CMC powder were added to a mixing tank with stirring and dispersion, and mixed at a low speed of 7 rpm for 110 minutes.

[0060] Low-speed high-viscosity mixing: add 27 parts of deionized water, and mix at a low speed of 10 rpm for 120 minutes to make the material in the mixing tank into a lump, and dry the dry material on the tank wall and the stirring paddle every 30 minutes. clean up.

[0061] Medium-speed medium-viscosity stirring: continue to add 21 parts of deionized water, carry out medium-speed st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com