System and method for continuously monitoring mercury concentration in oxygen-enriched device

A mercury concentration and oxygen-enriched technology, which is applied in measuring devices, color/spectral characteristic measurement, material excitation analysis, etc., can solve the problems of high-sensitivity components of corrosion testing instruments, large fluctuations, and affecting test data, etc., to prolong the life of the instrument and analysis accuracy, avoid fluctuations and damage to the instrument, and ensure the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

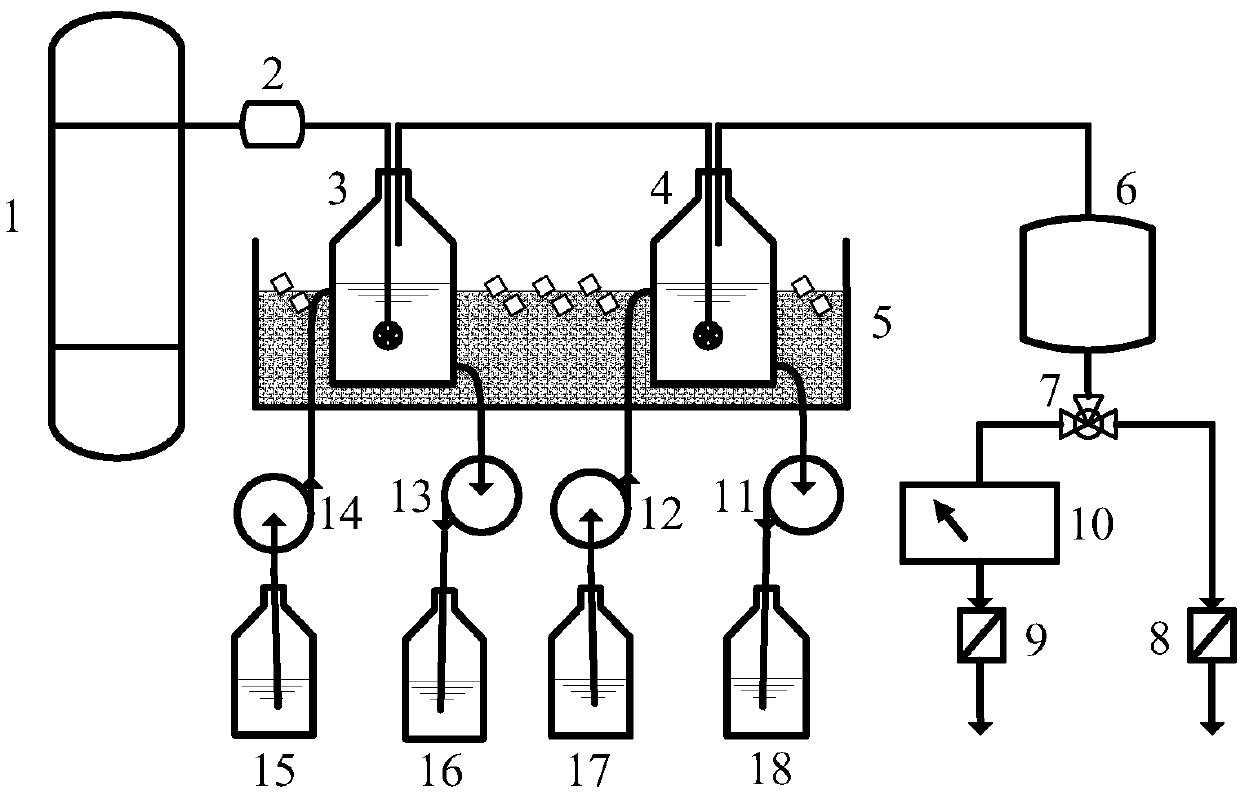

[0043] An application system for continuously monitoring mercury concentration in an oxygen-enriched combustion device of the present invention, such as figure 1 As shown, it mainly includes a flow control device 2 connected to the oxygen-enriched flue 1 by a special pipeline, two series-connected front reaction bottles 3 and a rear reaction bottle 4, a drying device 6, a three-way valve 7, an analysis The test system 10 and the exhaust gas path tail gas treatment device 8 and the test gas path tail gas treatment device 9 .

[0044] Wherein, the flow control device 2 should at least include an air pump and a flow meter. When the flow rate and pressure in the oxygen-enriched flue is high, the air pump does not work, and the flow meter is used to adjust the flue gas flow into the test system; Measure the gas, cooperate with the flow meter to adjust the flue gas flow into the test system.

[0045] When it is necessary to test the concentration of zero-valent mercury in the flue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com