A kind of imitation lime stone coating wall surface and its construction method

A technology of imitating limestone and paint, applied in the field of imitating limestone paint wall and its construction, can solve the problems of external wall decoration falling off for a long time, not in conformity with energy conservation and environmental protection, and high cost of natural stone, and achieve excellent waterproof, Good sandability and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

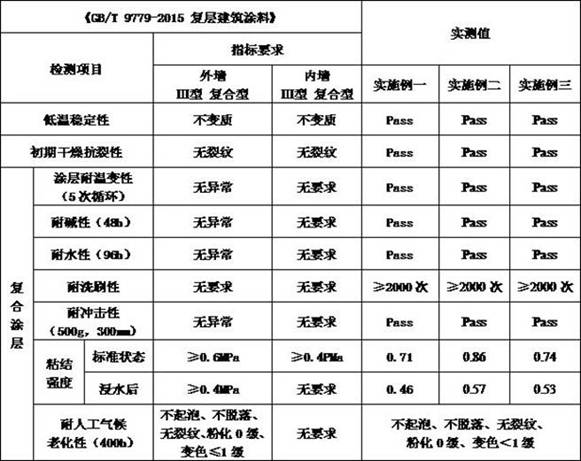

Examples

Embodiment 1

[0026] A lime stone-like paint wall surface, composed of the materials in the following table:

[0027]

[0028] The construction method of the above imitation limestone paint wall:

[0029] The first step, on the wall 1 that has been treated with the anti-alkali sealing primer, use a spatula to scrape the middle aggregate coating layer 2: the number of constructions is two, and the first drying time is ≥4h / 25℃. The second layer of batch scraping, after the second middle layer aggregate coating layer dries for ≥4h / 25℃, it can be smoothed with 200# coarse sandpaper; the total thickness of the two middle layer aggregate coating layers is 1.5-2mm; if the construction environment When the temperature is lower than 25°C, the drying time of each pass should be extended appropriately.

[0030] The second step is to construct the texture effect paint layer 3. This embodiment is to spray the color-point topcoat with a colorful paint spray gun: spray the color-point topcoat accordin...

Embodiment 2

[0034] A lime stone-like paint wall surface, composed of the materials in the following table:

[0035]

[0036] The construction method of the above imitation limestone paint wall:

[0037] The first step, on the wall 1 that has been treated with the anti-alkali sealing primer, use a spatula to scrape the middle aggregate coating layer 2: the number of constructions is two, and the first drying time is ≥4h / 25℃. The second layer of batch scraping, after the second middle layer aggregate coating layer dries for ≥4h / 25℃, it can be smoothed with 200# coarse sandpaper; the total thickness of the two middle layer aggregate coating layers is 1.5-2mm; if the construction environment When the temperature is lower than 25°C, the drying time of each pass should be extended appropriately.

[0038] The second step is to construct the texture effect paint layer 3. In this embodiment, use a natural seaweed sponge roller with a dipping plate to roll and coat the texture topcoat: before u...

Embodiment 3

[0042] A lime stone-like paint wall surface, composed of the materials in the following table:

[0043]

[0044] The construction method of the above imitation limestone paint wall:

[0045] The first step, on the wall 1 that has been treated with the anti-alkali sealing primer, use a spatula to scrape the middle aggregate coating layer 2: the number of constructions is two, and the first drying time is ≥4h / 25℃. The second layer of batch scraping, after the second middle layer aggregate coating layer dries for ≥4h / 25℃, it can be smoothed with 200# coarse sandpaper; the total thickness of the two middle layer aggregate coating layers is 1.5-2mm; if the construction environment When the temperature is lower than 25°C, the drying time of each pass should be extended appropriately.

[0046]Second step, construction texture effect coating layer 3, present embodiment comprises two kinds of effect layer coatings, construction order can be first with construction color point topco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com