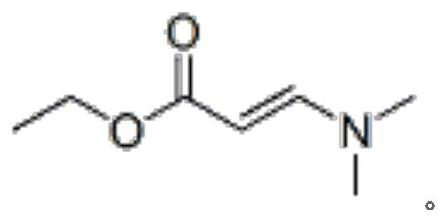

A kind of synthetic method of n,n-dimethylamino ethyl acrylate

A technology for the synthesis of ethyl dimethylaminoacrylate, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as harsh process conditions, unsuitable for industrial production, and high by-products, and achieve friendly reaction conditions , Low production cost and reduced by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

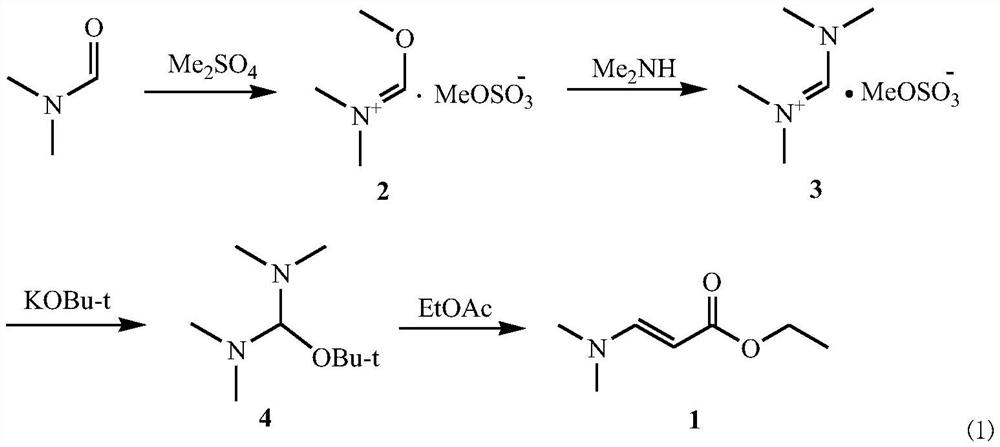

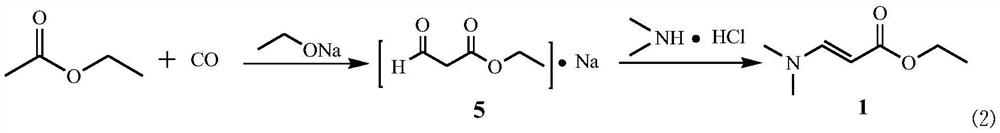

Method used

Image

Examples

Embodiment 1

[0066] Add ethyl acetate (88g, 1mol), dimethylamine (45g, 1mol), xylene 250mL and solid base catalyst 4.4g into the autoclave, feed CO, control the pressure to 1MPa and raise the temperature to 50°C, keep stirring and react for 4h , the CO pressure no longer drops, cool to room temperature, filter, reclaim the solid base catalyst, divide the water layer after adding the solvent xylene to the filtrate, reclaim the solvent (xylene) in the organic layer, and distill the residue under reduced pressure; collect 118~121°C ( 7.5mmHg) to obtain 136.3g of N,N-ethyl dimethylaminoacrylate as the target product, with a yield of 95.3% and an HPLC content of 99.8%.

Embodiment 2

[0068] Add ethyl acetate (88g, 1mol), dimethylamine (54g, 1.2mol), xylene 250mL and solid base catalyst 4.4g into the autoclave, feed in CO, control the pressure to 1MPa and raise the temperature to 50°C to keep stirring and react 4h, the pressure of CO no longer drops, cool to room temperature, filter, recover the solid base catalyst, add the solvent xylene to the filtrate and separate the water layer, recover the solvent (xylene) from the organic layer, and distill the residue under reduced pressure; collect 118~121 °C (7.5 mmHg) fraction, 136.5 g of the target product N,N-ethyl dimethylaminoacrylate was obtained, the yield was 95.5%, and the HPLC content was 99.5%.

Embodiment 3

[0070] Add ethyl acetate (88g, 1mol), dimethylamine (45g, 1mol), xylene 100mL and solid base catalyst 8.8g into the autoclave, feed CO, control the pressure to 1MPa and raise the temperature to 50°C and keep stirring for 2.5 h, CO pressure no longer drops, cool to room temperature, filter, recover the solid base catalyst, add the solvent xylene to the filtrate and divide the water layer, recover the solvent (xylene) from the organic layer, and distill the residue under reduced pressure; collect 118~121 °C (7.5 mmHg) fraction, 133.5 g of the target product N,N-ethyl dimethylaminoacrylate was obtained, the yield was 93.4%, and the HPLC content was 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com