A method for preparing a novel sodium-ion battery negative-electrode material

A negative electrode material and sodium electricity technology, which is applied in the field of preparation of novel sodium electricity negative electrode materials, can solve the problems of low preparation efficiency, many chemical reagents, cycle deterioration, etc. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

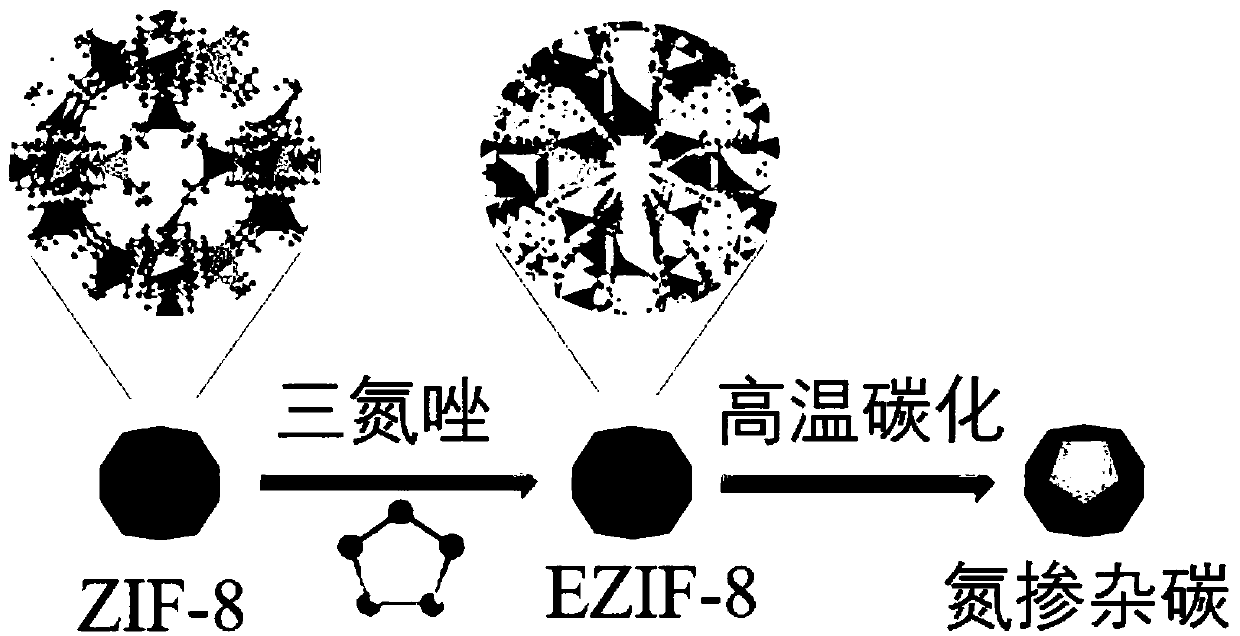

[0034] Step 1, take 4mmol of zinc nitrate hexahydrate and dissolve it in 20mL of methanol solution, then quickly add it to 25mL of methanol solution containing 18mmol of 2-methylimidazole, let stand for 24h and then centrifuge to collect the white precipitate at the bottom to obtain the following: Zn 2+ Metal-organic framework (ZIF-8) as the coordination center;

[0035] Step 2. Dissolve 0.5g metal-organic framework (ZIF-8) in 50mL methanol solution, then add 1.0g triazole, stir evenly and let it stand for 3 days, then centrifuge to collect the chain exchange product (EZIF-8 );

[0036] Step 3: Weigh 100 mg of the chain exchange product (EZIF-8) and place it in a tube furnace, raise the temperature to 800°C at a rate of 5°C / min, calcinate at 800°C for 2 hours, and then cool;

[0037] Step 4. After cooling, put it into 1mol / L hydrochloric acid solution, soak for 6 hours, remove the zinc element, then dry it in a vacuum oven at 80°C for 6 hours, and collect the nitrogen-doped ...

Embodiment 2

[0044] Step 1. Weigh 5mmol of zinc acetate and dissolve it in 5mL of methanol solution, then quickly add it to 75mL of methanol solution containing 15mmol of 2-ethylimidazole, let stand for 36h and then centrifuge to collect the white precipitate at the bottom to obtain Zn 2+ Metal-organic framework (ZIF-8) as the coordination center;

[0045] Step 2. Dissolve 0.5g metal-organic framework (ZIF-8) in 250mL methanol solution, then add 1.5g triazole, stir well and let it stand for 4 days, then centrifuge to collect the chain exchange product (EZIF-8 );

[0046] Step 3: Weigh 100 mg of the chain exchange product (EZIF-8) and place it in a tube furnace, raise the temperature to 780°C at a rate of 15°C / min, calcinate at 780°C for 3 hours, and then cool;

[0047] Step 4. After cooling, put it into 4mol / L hydrochloric acid solution, soak for 10 hours, remove the zinc element, then dry it in a vacuum oven at 90°C for 8 hours, and collect the nitrogen-doped material used for the new ty...

Embodiment 3

[0050] Step 1. Weigh 2mmol of zinc acetate dihydrate and 2mmol of zinc nitrate and dissolve them in 40mL of methanol solution, then quickly add them to 240mL of methanol solution containing 24mmol of 2-nitroimidazole, let stand for 32h and centrifuge to collect the bottom White precipitate, obtained as Zn 2+ Metal-organic framework (ZIF-8) as the coordination center;

[0051] Step 2: Dissolve 0.5g metal-organic framework (ZIF-8) in 25mL methanol solution, then add 0.5g triazole, stir evenly and let stand for 3 days, then centrifuge to collect the chain exchange product (EZIF-8 );

[0052] Step 3: Weigh 100 mg of the chain exchange product (EZIF-8) and place it in a tube furnace, raise the temperature to 800°C at a rate of 10°C / min, calcinate at 800°C for 2 hours, and then cool;

[0053] Step 4. After cooling, put it into 2mol / L hydrochloric acid solution, soak for 8 hours, remove the zinc element, then dry it in a vacuum oven at 100°C for 10 hours, and collect the nitrogen-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coulombic efficiency | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com