Thermoplastic film packaging machine

A thermoplastic film and packaging machine technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the problems of thermoplastic film waste, size mismatch, etc., to improve processing efficiency, avoid waste, and shorten the time to return to the original position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

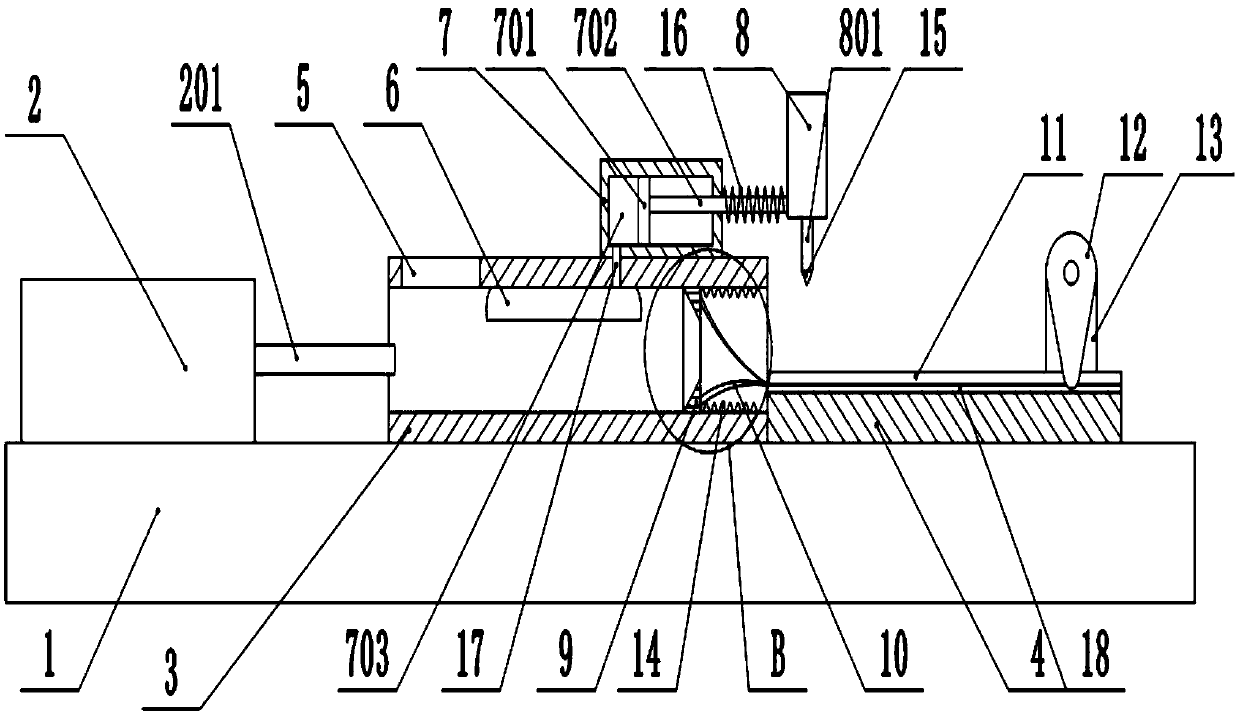

[0023] The following is a further detailed description through specific implementations:

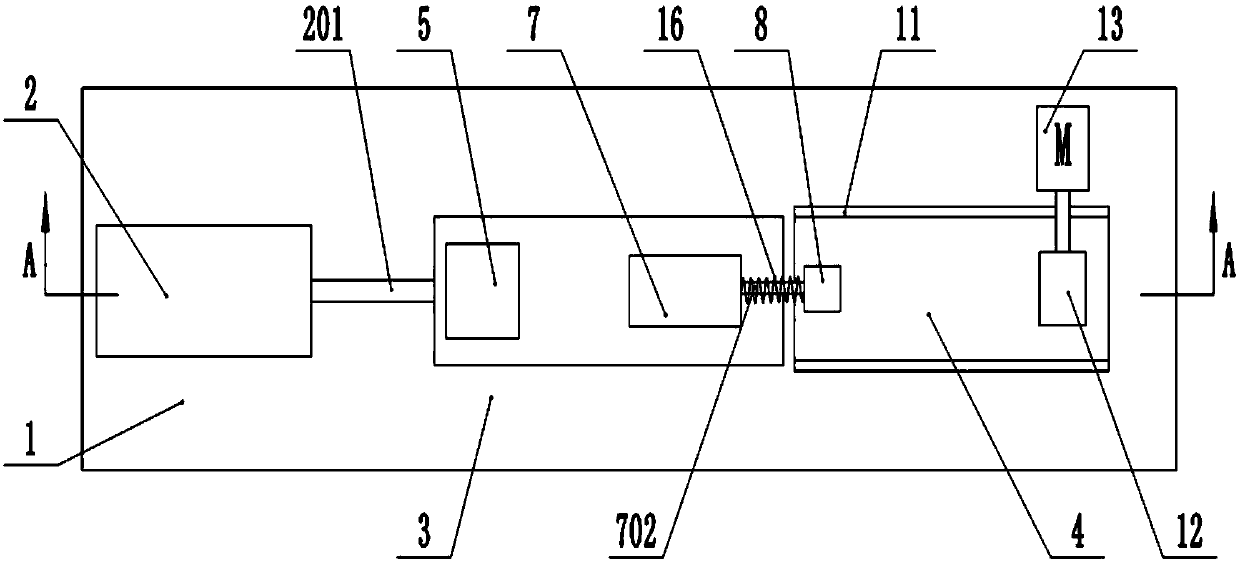

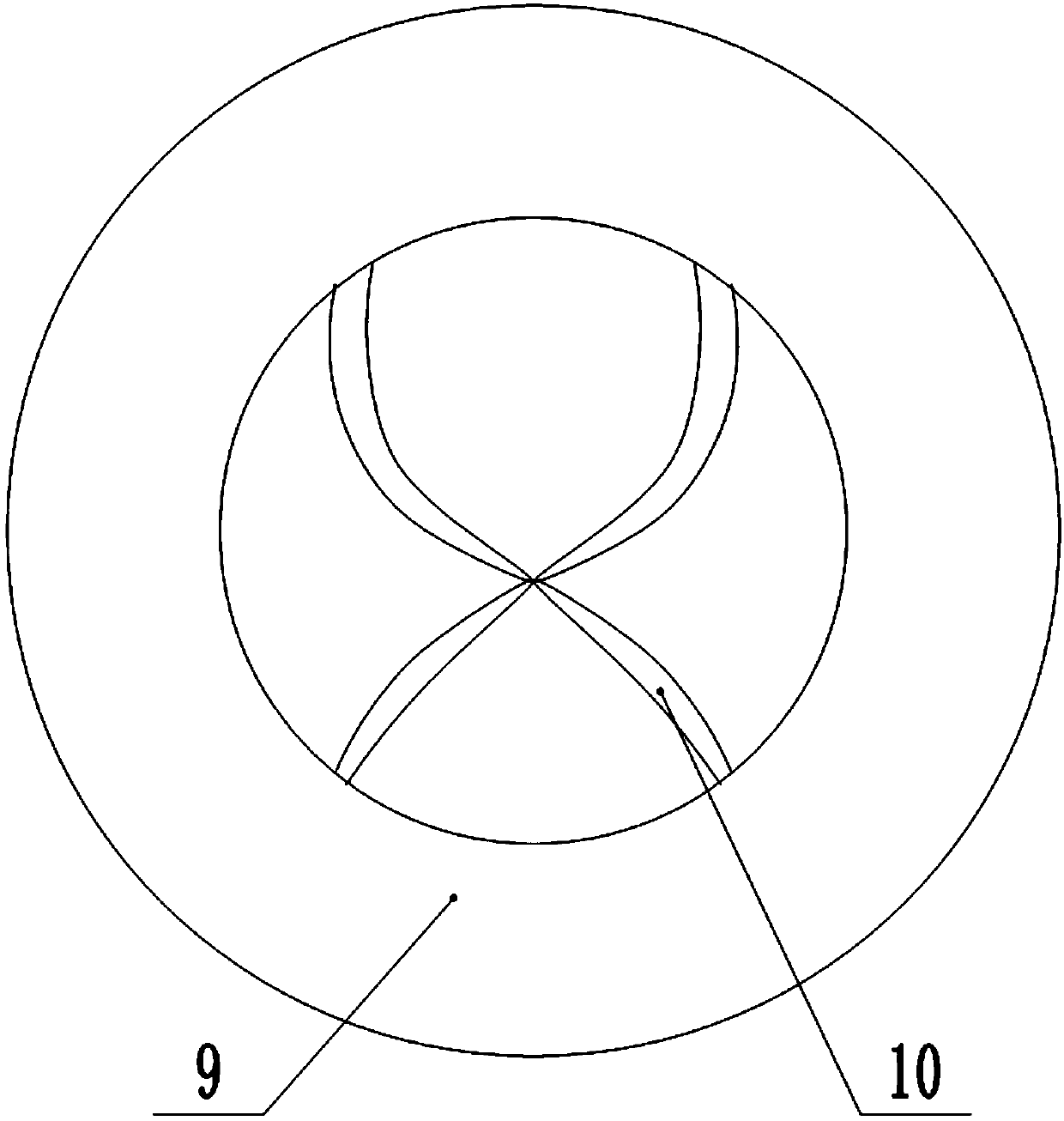

[0024] The reference signs in the drawings of the specification include: workbench 1, first cylinder 2, sleeve 3, conveying plate 4, feed port 5, air bag 6, second cylinder 7, third cylinder 8, annular sleeve 9, elastic Sheet 10, clamping block 11, cam 12, servo motor 13, first spring 14, cutter 15, second spring 16, pipe 17, groove 18, first piston rod 201, second piston plate 701, second The piston rod 702, the second rodless cavity 703, and the third piston rod 801.

[0025] The embodiment is basically as attached figure 1 , figure 2 with image 3 Shown:

[0026] A thermoplastic film packaging machine includes a worktable 1 on which a first cylinder 2, a sleeve 3 and a thermoplastic film conveying mechanism are sequentially fixed from left to right.

[0027] The first cylinder 2 is connected to the worktable 1 by bolts, and the first piston rod 201 of the first cylinder 2 is coaxial with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com