Automobile windshield light shielding and entertainment multifunctional composite glass structure and manufacturing method thereof

A composite glass, multi-functional technology, used in glass manufacturing equipment, windshields, manufacturing tools, etc., to achieve flexible light isolation and privacy protection, great practicability, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

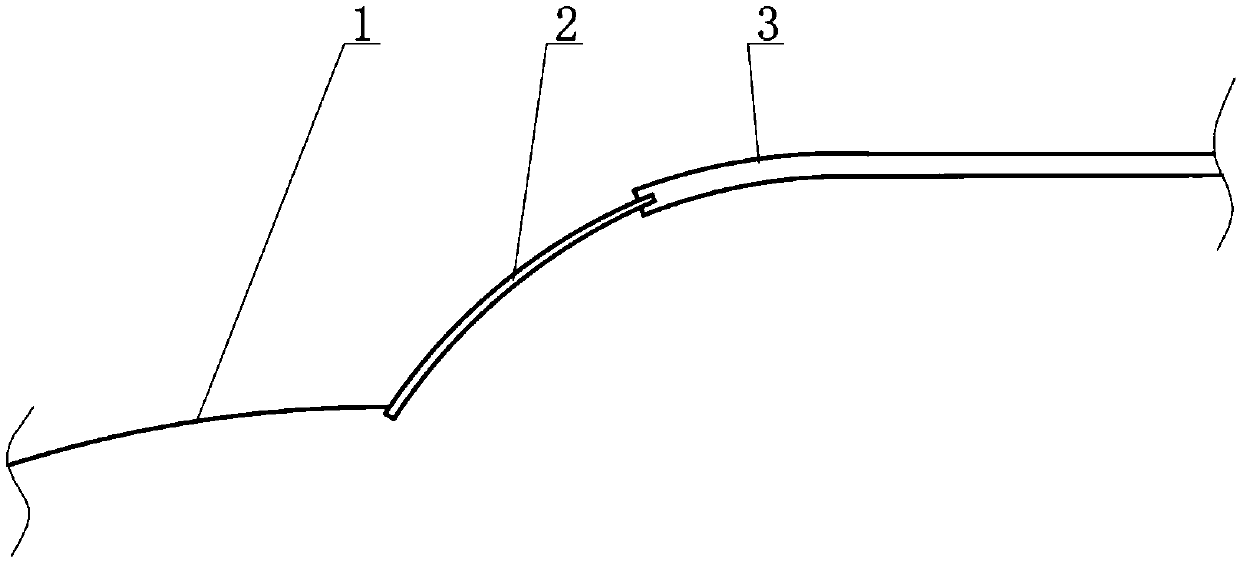

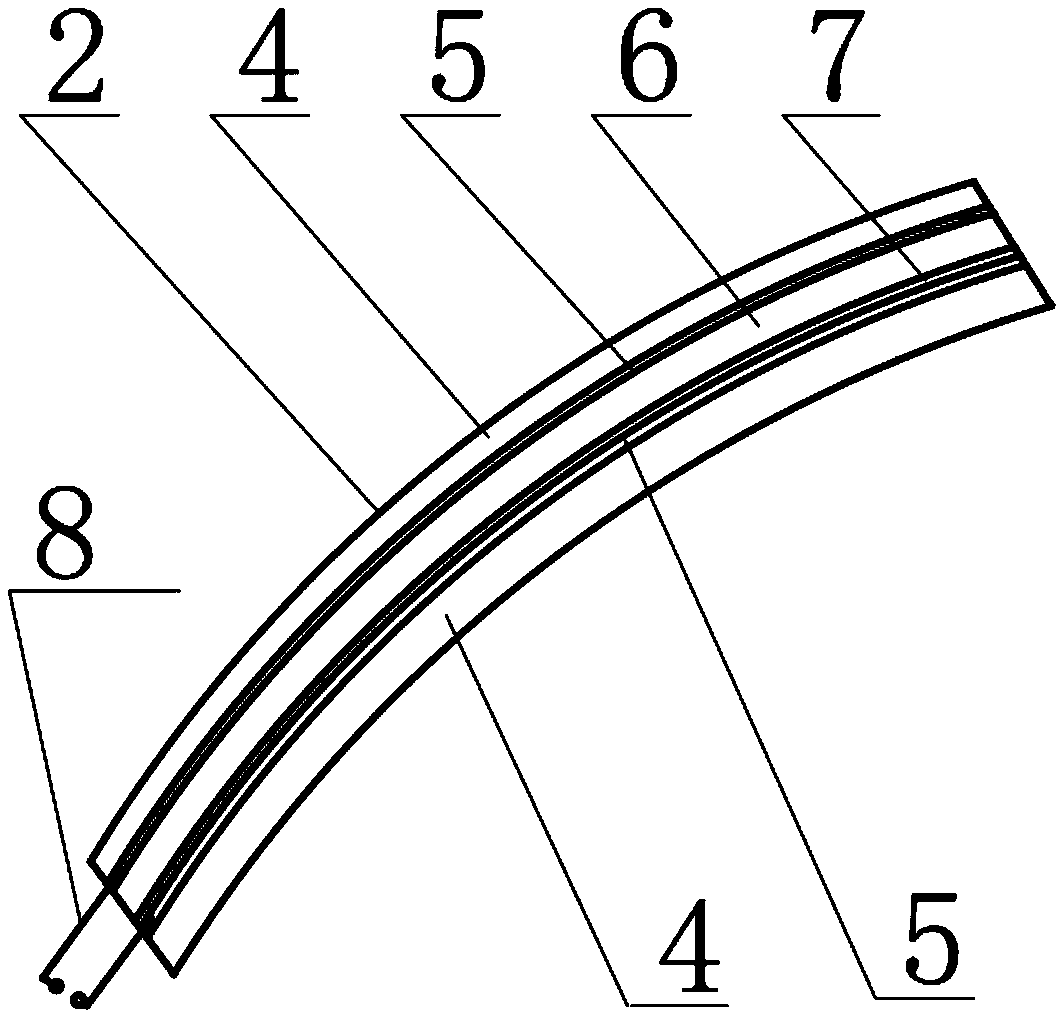

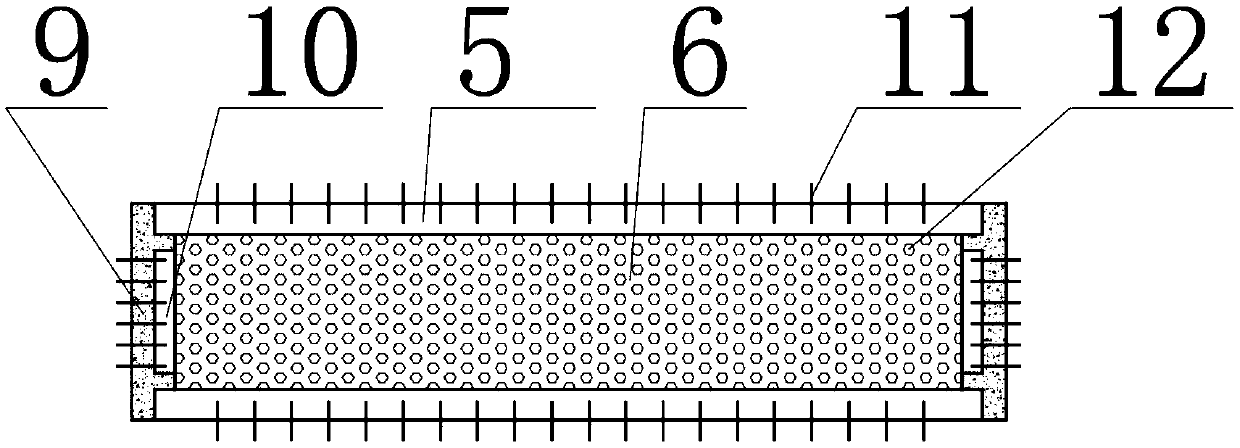

[0026] A multifunctional composite glass structure for shading and entertainment of a front shield, the composite front windshield is arranged between the engine compartment cover 1 and the roof cover 3, and the composite front windshield includes a glass substrate 4, an indium tin oxide Conductive layer 5, ink screen structure 6, conductive and thermally conductive layer 7, indium tin oxide conductive layer 5, glass substrate 4; side electrostatic plates 10 are arranged on both sides of the composite front windshield corresponding to the A-pillar of the car; indium tin oxide Both the conductive layer 5 and the side electrostatic plate 10 are connected to the DC circuit system 8 through the electrostatic plate cable 11, and the electrostatic plate cable 11 circuit externally connected to the indium tin oxide conductive layer 5 and the electrostatic plate cable 11 circuit externally connected to the side electrostatic plate 10 are Parallel relationship; the ink screen structure ...

Embodiment 2

[0041] The whole is consistent with Example 1, the difference is:

[0042] Wherein the manufacturing process of the composite front windshield comprises the following steps:

[0043] 1) Preparation before production

[0044] ① Preparation of vitreous body raw materials: prepare 85Kg of silicon dioxide and 15Kg of potassium oxide by weight;

[0045] The composite glass structure produced by this embodiment has a light transmittance of 10% when the full screen is inked, and a light transmittance of 70% when the full screen is translucent, and it is used as the only external material in a closed space at 50°C in an air environment The temperature rise is 7°C in 2 hours, the working temperature is -40°C-200°C, the stability is good, and the service life is not less than 5 years.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com