Repair method for corroded steel structure parts in transformer substation

A repair method and technology for steel structural parts, which are applied in the field of substation maintenance, can solve the problems of difficult handling, long processing time of the repair method, cumbersome and inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

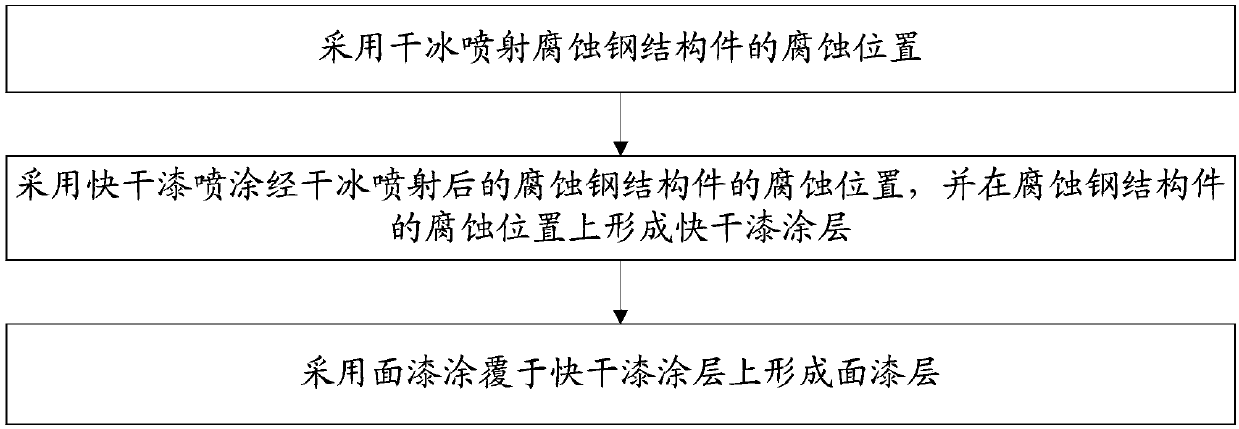

[0045] The repair method for corroded steel structural parts in substations, that is, the quick repair plan for large-area corroded steel structural parts in substations, the specific steps are as follows:

[0046] (1) Use dry ice sandblasting, adjust the pressure to 0.4MPa, and the airflow to 0.35 cubic meters per minute, and quickly peel off the primer, topcoat and corrosion products on the corrosion position on the surface of the steel structure.

[0047] (2) Use quick-drying zinc-rich epoxy to paint the cleaned substrate, and use the spraying method, the spraying pressure is 0.2MPa, and the thickness of the primer layer is controlled at 30μm.

[0048] (3) After the treatment in step (2) for 30 minutes, use two-component polyurethane paint to coat the structural parts with a spraying method, the spraying pressure is 0.2MPa, and the thickness is controlled at about 50μm.

[0049] The repair time of the repair method for corroded steel structural parts in the entire substatio...

Embodiment 2

[0051] The repair method of corroded steel structural parts in the substation, that is, the quick repair plan for the steel structural parts with a large area of paint peeling off in the substation, the specific steps are as follows:

[0052] (1) The peeling of the paint layer is mainly the peeling of the topcoat. Use dry ice sandblasting, adjust the pressure to 0.4MPa, and the airflow to 0.3 cubic meters per minute. Quickly peel off the finish paint on the surface of the steel structure.

[0053] (2) Use quick-drying zinc-rich epoxy to paint the cleaned substrate, and use spraying method, the spraying pressure is 0.6MPa, and the thickness is controlled at about 30μm.

[0054] (3) After the treatment in step (2) for 30 minutes, use two-component polyurethane paint to coat the structural parts with a spraying method, the spraying pressure is 0.5MPa, and the thickness is controlled at about 50μm.

[0055] The repair time of the repair method for corroded steel structural par...

Embodiment 3

[0057] The repair method for corroded steel structural parts in substations, that is, the rapid repair plan for large-area corroded steel structural parts in substations, the specific steps are as follows: (1) Use dry ice sandblasting, adjust the pressure to 0.8MPa, and the airflow to 0.6 cubic meters per minute. Quickly strip the primer, topcoat and corrosion products on the corrosion site on the surface of the steel structure.

[0058] (2) Use quick-drying zinc-rich epoxy to paint the cleaned substrate, and use spraying method, the spraying pressure is 0.7MPa, and the thickness is controlled at about 45μm.

[0059] (3) After the treatment in step (2) for 30 minutes, use epoxy zinc-rich paint to coat the structural parts with a spraying method, the spraying pressure is 0.5MPa, and the thickness is controlled at about 45μm. The finish color is gray.

[0060] The repair time of the repair method for corroded steel structural parts in the entire substation is only 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com