an emulsifying machine

A technology of emulsification machine and emulsification tank, which is applied in the field of emulsification machine, can solve the problems of small impact force of emulsification tank, single material movement track, difficult cleaning of emulsification tank, etc., and achieve the effect of improving stability and emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

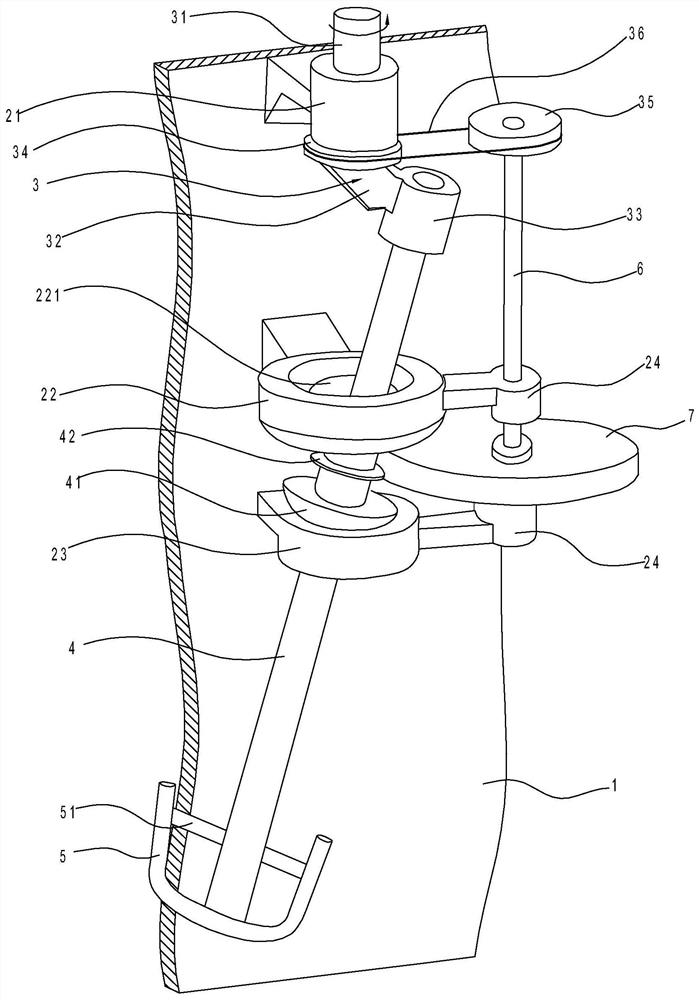

[0012] Such as figure 1 As shown, the emulsification machine in this implementation includes an emulsification tank 1, a drive motor, an emulsification shaft 4, a stirring blade 5, a support seat 21, an upper support 22, a lower support 23, a driving member 3, a belt 36, and a driven belt Wheel 35, rotating shaft 6, spur gear 7, external ring gear 42.

[0013] Among them, the emulsification shaft 4 is installed obliquely in the emulsification tank 1, the stirring blade 5 is arranged at the lower end of the emulsification shaft 4, the stirring blade 5 points to the intersection of the side wall and the bottom wall of the emulsification tank 1, and the inner wall of the emulsification tank 1 is arranged from top to bottom. There are a support base 21, an upper support base 22 and a lower support base 23, and the support base 21 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com