Coaxial active packaging structure of electric absorption modulation sealed laser

A technology of electro-absorption modulation and packaging structure, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of difficult process and unfavorable optical path coupling, so as to reduce the difficulty of process, reduce the difficulty of coupling, and reduce the precision requirements of patch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

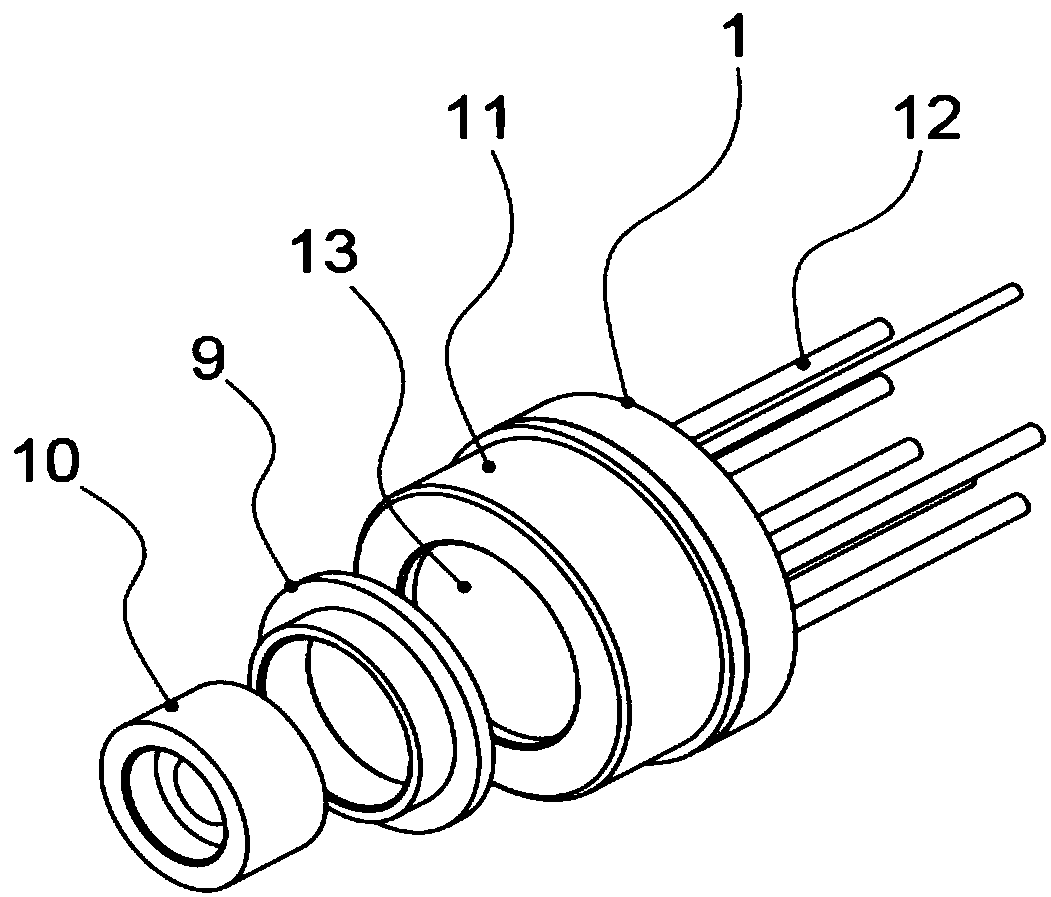

[0022] The coaxial active package structure of the electroabsorption modulated sealed laser, such as figure 2 As shown, it includes a tube body 1 processed by nickel-gold electroplating. One end of the tube body 1 protrudes from a conductive gold pin 12 , and the other end is covered with a cap-shaped metal shell 11 . The top of the cap-shaped metal shell 11 (the end away from the conductive gold pin 12) is a ring-shaped concave sealing glass 13 that is recessed from the top surface of the tube body 1. The top of the cap-shaped metal shell 11 is equipped with a ring-shaped The adjustable metal seat 9 of the sleeve structure, the bottom of the adjustable metal seat 9 extends outwards to form an annular sealing ring and is close to the top surface of the cap-shaped metal shell 11, while the inner ring of the annular sleeve is aligned with the sealing ring. The annular shape of the glass 13 is concave and coaxial with it. The lens 10 is passed through the annular casing of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com