High-nickel ternary positive electrode material washing method

A positive electrode material, high-nickel technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problem of not being able to fully wash off the residual alkali, achieve the effect of improving safety, reducing alkalinity, and reducing the content of residual alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Weigh 25g of NCM622, add 100g of deionized water, stir for 5min, and ultrasonicate for 5min at a frequency of 28khz and a power of 100w;

[0028] 2. Filter and burn back in an oxygen environment at 700°C for 5 hours;

[0029] 3. Take 5g of the dried powder and add 95g of deionized water, stir for 5min and then filter with suction, and measure the content of lithium carbonate and lithium hydroxide in the filtrate.

Embodiment 2

[0031] 1. Weigh 25g of NCM622, add 100g of deionized water, stir for 5min, and ultrasonicate for 2min at a frequency of 28khz and a power of 100w;

[0032] 2. Filter and burn back in an oxygen environment at 700°C for 5 hours;

[0033] 3. Take 5g of the dried powder and add 95g of deionized water, stir for 5min and then filter with suction, and measure the content of lithium carbonate and lithium hydroxide in the filtrate.

Embodiment 3

[0035] 1. Weigh 25g of NCM622, add 100g of deionized water, stir for 5min, and ultrasonicate for 10min at a frequency of 28khz and a power of 100w;

[0036] 2. Filter and burn back in an oxygen environment at 700°C for 5 hours;

[0037] 3. Take 5g of the dried powder and add 95g of deionized water, stir for 5min and then filter with suction, and measure the content of lithium carbonate and lithium hydroxide in the filtrate.

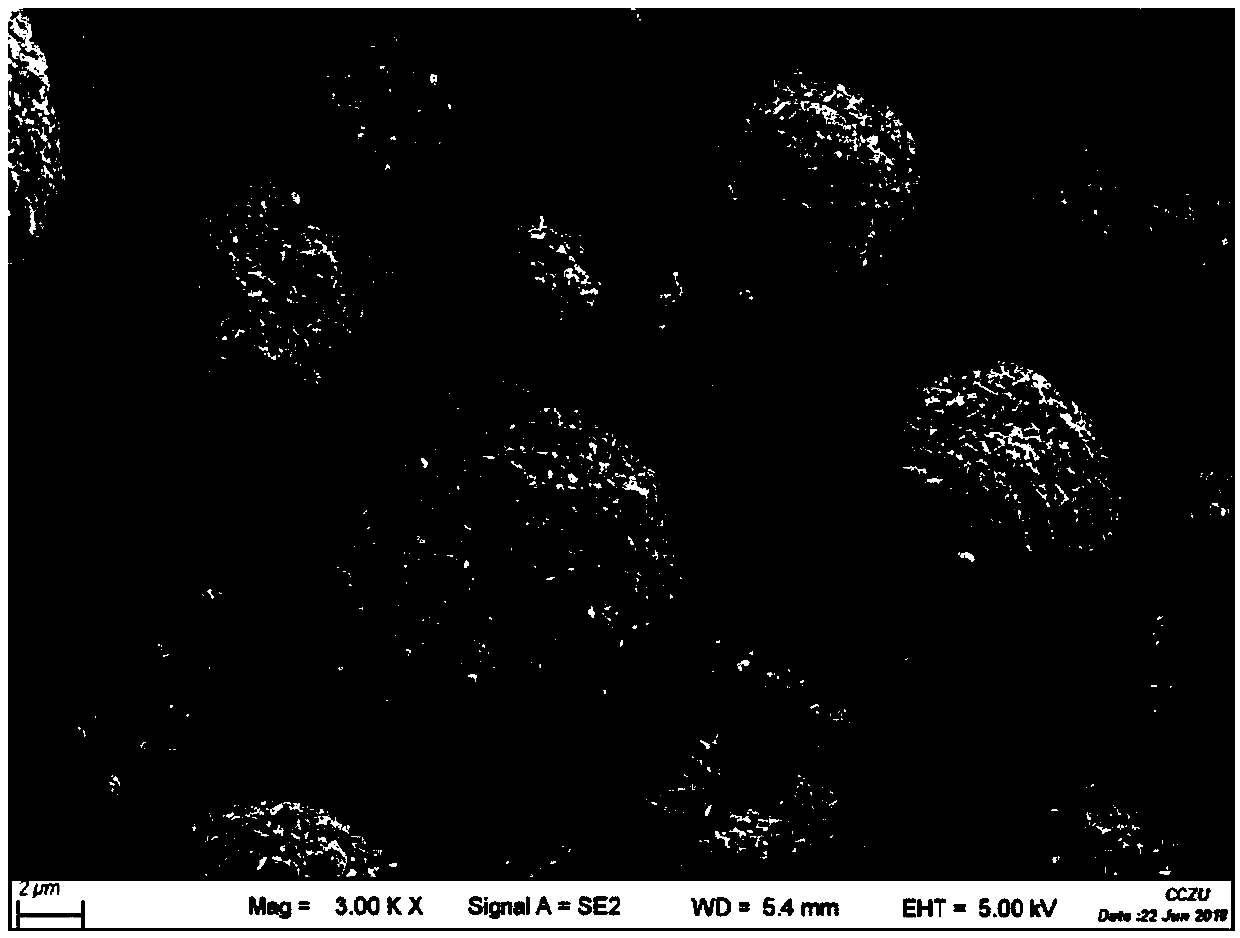

[0038] Please refer to figure 1 , the XRD results of the ternary cathode material before and after ultrasonic washing in Example 1 show that the particle size distribution before and after ultrasonic washing all presents a normal distribution. After the water-washed materials are ultrasonically treated, the particle size distribution curve shifts to the right as a whole and extends to both ends. D10 decreases and D90 increases, indicating that ultrasonic treatment will cause a small amount of fine powder of the material, but the overall particle size di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com