Method for preparing stainless steel-based micro-nano array beta-PbO2 anode material

An anode material, stainless steel technology, applied in chemical instruments and methods, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve problems such as low electrocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

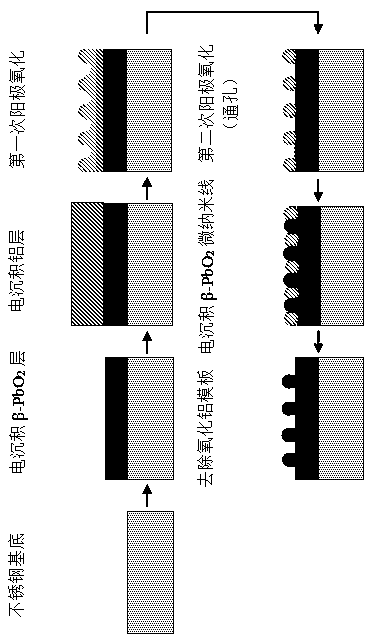

[0043] Embodiment 1: as image 3 As shown, a stainless steel-based micro-nano array β-PbO 2 The method for anode material, concrete steps are as follows:

[0044] (1) In electrolyte A, the stainless steel plate was used as the substrate, and β-PbO was electrodeposited on the stainless steel plate substrate by the constant current electrodeposition method 2 layer to obtain stainless steel-based β-PbO 2 layer; wherein the constant current electrodeposition method adopts a double-cathode system, the cathode is a stainless steel plate, an aluminum plate, a lead plate or a platinum plate, the pH value of the electrolyte A is 3, and the electroplating solution A is Pb(NO 3 ) 2 -NaF-Cu(NO 3 ) 2 Electrolyte, Pb(NO 3 ) 2 -NaF-Cu(NO 3 ) 2 The electrolyte contains Pb(NO 3 ) 2 190.0g / L, NaF 0.5g / L, Cu(NO 3 ) 2 15.0g / L; The constant current electrodeposition method includes a constant current electrodeposition and a second constant current electrodeposition, the temperature ...

Embodiment 2

[0053] Embodiment 2: as image 3 As shown, a stainless steel-based micro-nano array β-PbO 2 The method for anode material, concrete steps are as follows:

[0054] (1) In electrolyte A, the stainless steel plate was used as the substrate, and β-PbO was electrodeposited on the stainless steel plate substrate by the constant current electrodeposition method 2 layer to obtain stainless steel-based β-PbO 2 The constant current electrodeposition method adopts a double-cathode system, the cathode is a stainless steel plate, an aluminum plate, a lead plate or a platinum plate, the pH value of the electrolyte A is 1, and the electroplating solution A is Pb(NO 3 ) 2 -NaF-Cu(NO 3 ) 2 Electrolyte, Pb(NO 3 ) 2 -NaF-Cu(NO 3 ) 2 The electrolyte contains Pb(NO 3 ) 2 210.0g / L, NaF 1.0g / L, Cu(NO 3 ) 2 20.0g / L; The constant current electrodeposition method includes a constant current electrodeposition and a second constant current electrodeposition, the temperature of the first co...

Embodiment 3

[0064] Embodiment 3: as image 3 As shown, a stainless steel-based micro-nano array β-PbO 2 The method for anode material, concrete steps are as follows:

[0065] (1) In electrolyte A, the stainless steel plate was used as the substrate, and β-PbO was electrodeposited on the stainless steel plate substrate by the constant current electrodeposition method 2 layer to obtain stainless steel-based β-PbO 2 The constant current electrodeposition method adopts a double-cathode system, the cathode is a stainless steel plate, an aluminum plate, a lead plate or a platinum plate, the pH value of the electrolyte A is 2, and the electroplating solution A is Pb(NO 3 ) 2 -NaF-Cu(NO 3 ) 2 Electrolyte, Pb(NO 3 ) 2 -NaF-Cu(NO 3 ) 2 The electrolyte contains Pb(NO 3 ) 2 180.0g / L, NaF 0.5g / L, Cu(NO 3 ) 2 15.0g / L; The constant current electrodeposition method includes a constant current electrodeposition and a second constant current electrodeposition, the temperature of the first co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com