A stainless steel-based β-pbo 2 -mno 2 - CEO 2 -zro 2 Preparation method of inert composite anode material

A technology of -pbo2-mno2-ceo2-zro2, inert composite anode, applied in the direction of electrolytic inorganic material coating, electrodes, electrolytic components, etc., to achieve the effect of increasing surface roughness, improving use efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

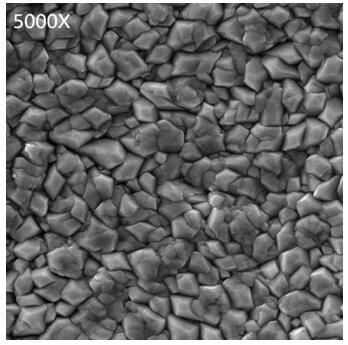

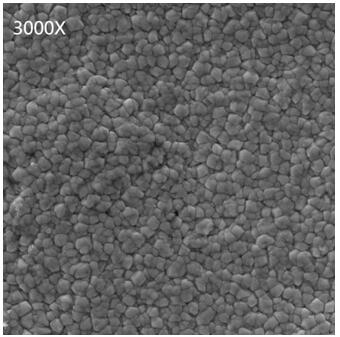

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of stainless steel base β-PbO 2 -MnO 2 -CeO 2 -ZrO 2 The preparation method of inert composite anode material, concrete steps are as follows:

[0024] (1) Mechanically grind the mesh stainless steel substrate, soak it in an alkaline degreasing agent for 20 minutes at a temperature of 50°C, and then immerse it in a mixed acid system (nitric acid-hydrochloric acid system) for 80 seconds to obtain an activated mesh. shaped stainless steel substrate; the pore size of the mesh stainless steel substrate is 600 μm; the alkaline degreaser contains 40g / L trisodium phosphate (Na 3 PO 4 ) and 15g / L sodium silicate (Na 2 SiO 3 ) mixed aqueous solution; the mass fraction of nitric acid in the nitric acid-hydrochloric acid system is 20%, and the mass fraction of hydrochloric acid is 30%;

[0025] (2) Use the activated mesh stainless steel substrate in step (1) as the anode, and the copper plate as the cathode, at a temperature of 40°C and an anode current ...

Embodiment 2

[0028] Embodiment 2: A kind of stainless steel base β-PbO 2 -MnO 2 -CeO 2 -ZrO 2 The preparation method of inert composite anode material, concrete steps are as follows:

[0029] (1) Mechanically grind the mesh stainless steel substrate, soak it in an alkaline degreaser for 25 minutes at a temperature of 50°C, and then soak it in a mixed acid system (nitric acid-hydrochloric acid system) for 70 seconds to obtain an activated mesh. shaped stainless steel substrate; the pore size of the mesh stainless steel substrate is 700 μm; the alkaline degreaser contains 40g / L trisodium phosphate (Na 3 PO 4 ) and 15g / L sodium silicate (Na 2 SiO 3 ) mixed aqueous solution; the mass fraction of nitric acid in the nitric acid-hydrochloric acid system is 15%, and the mass fraction of hydrochloric acid is 35%;

[0030] (2) With the activated mesh stainless steel substrate in step (1) as the anode and the copper plate as the cathode, at a temperature of 50°C and an anode current density of...

Embodiment 3

[0032] Embodiment 3: A kind of stainless steel base β-PbO 2 -MnO 2 -CeO 2 -ZrO 2 The preparation method of inert composite anode material, concrete steps are as follows:

[0033] (1) Mechanically grind the mesh stainless steel substrate, soak it in an alkaline degreaser for 30 minutes at a temperature of 50°C, and then soak it in a mixed acid system (nitric acid-hydrochloric acid system) for 60 seconds to obtain an activated mesh. shaped stainless steel substrate; the pore size of the mesh stainless steel substrate is 800 μm; the alkaline degreaser contains 40g / L trisodium phosphate (Na 3 PO 4 ) and 15g / L sodium silicate (Na 2 SiO 3 ) mixed aqueous solution; the mass fraction of nitric acid in the nitric acid-hydrochloric acid system is 25%, and the mass fraction of hydrochloric acid is 25%;

[0034] (2) With the activated mesh stainless steel substrate in step (1) as the anode and the copper plate as the cathode, at a temperature of 60°C and an anode current density of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com