A resource utilization method and system for pva waste adhesives

A binder and recycling technology, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of ignoring the resource utilization of PVA waste binders, poor treatment effect, Deal with low efficiency and other issues to achieve the effect of resource utilization, load reduction and COD reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

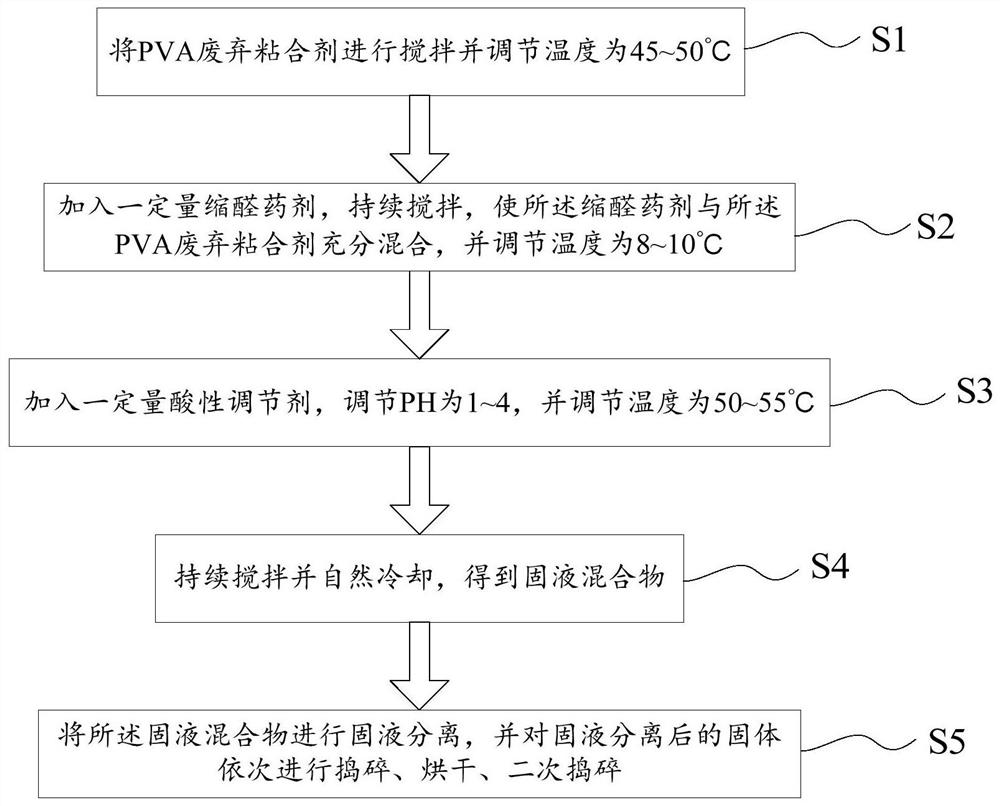

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: The PVA waste binder is a high-concentration fluid state PVA waste binder.

[0051] Add 300L of high-concentration fluid PVA waste binder into the 1m3 reactor through the raw water tank, start the stirring paddle for continuous stirring, and adjust the system temperature in the reactor to 45-50°C. After adjusting the temperature, slowly introduce 23.5L of n-butyraldehyde into the reaction kettle through the first chemical tank, keep the stirring paddle continuously stirring, and adjust the system temperature in the reaction kettle to 8-10°C. Slowly add 20% hydrochloric acid into the reaction kettle through the second chemical tank, adjust the pH of the reaction kettle system to ≈2, gradually increase the system temperature in the reaction kettle to 55°C, stop heating after holding for half an hour, and continue stirring with the stirring blade Until the system was cooled to room temperature, the solid and liquid separated. Two batches of continuous produc...

Embodiment 2

[0056] Embodiment 2: The PVA waste binder is a high-concentration jelly-like PVA waste binder.

[0057] Add 500kg of high-concentration jelly-like PVA waste adhesives into the 1m3 reactor through the raw water tank, start the stirring paddle for continuous stirring, and adjust the system temperature in the reactor to 45-50°C. After adjusting the temperature, slowly introduce 38L of n-butyraldehyde into the reaction kettle through the first chemical tank, keep the stirring paddle continuously stirring, and adjust the system temperature in the reaction kettle to 8-10°C. Slowly add 20% hydrochloric acid into the reaction kettle through the second chemical tank, adjust the pH of the reaction kettle system to ≈2, gradually increase the system temperature in the reaction kettle to 55°C, stop heating after holding for half an hour, and continue stirring with the stirring blade Until the system was cooled to room temperature, the solid and liquid separated. Two batches of continuous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com