Method for improving degreasing strength of additive manufacturing formed ceramic part

A technology for ceramic parts and additive manufacturing, which is applied in the field of improving the degreasing strength of additively manufactured ceramic parts. It can solve the problems that the viscosity of ceramic slurry is greatly affected and cannot meet the requirements of slurry preparation, so as to avoid drying cracks and improve degreasing. Strength and low pyrolysis loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

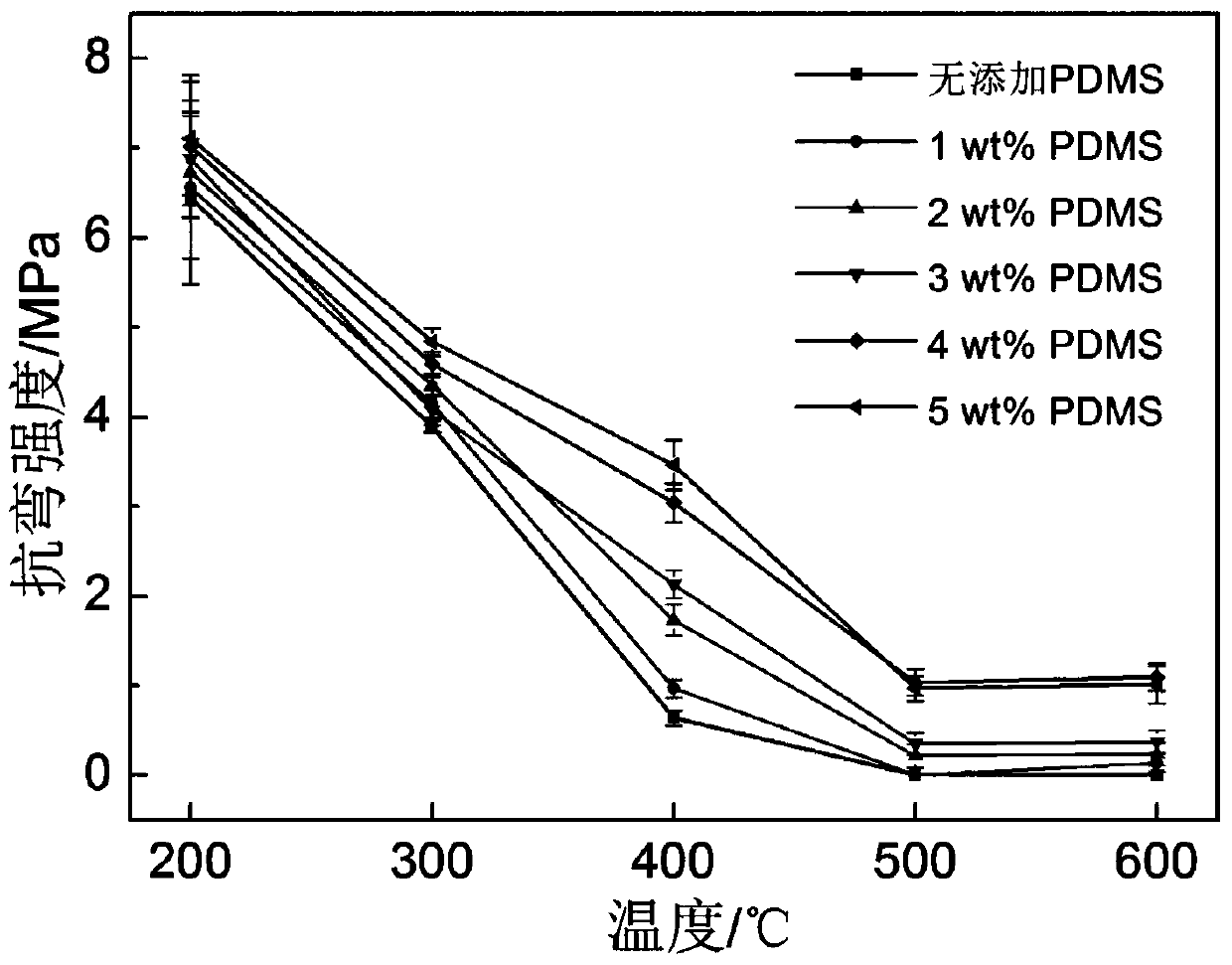

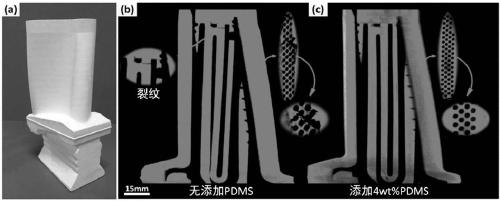

[0042] The indirect additive manufacturing of ceramic parts is realized by adopting the molding process of ceramic parts based on light-cured resin prototypes. 1-5wt% polydimethylsiloxane (PDMS) was added to the raw materials to make standard samples, and compared with samples without any binder, in order to analyze the effect of PDMS on the medium temperature strength influences.

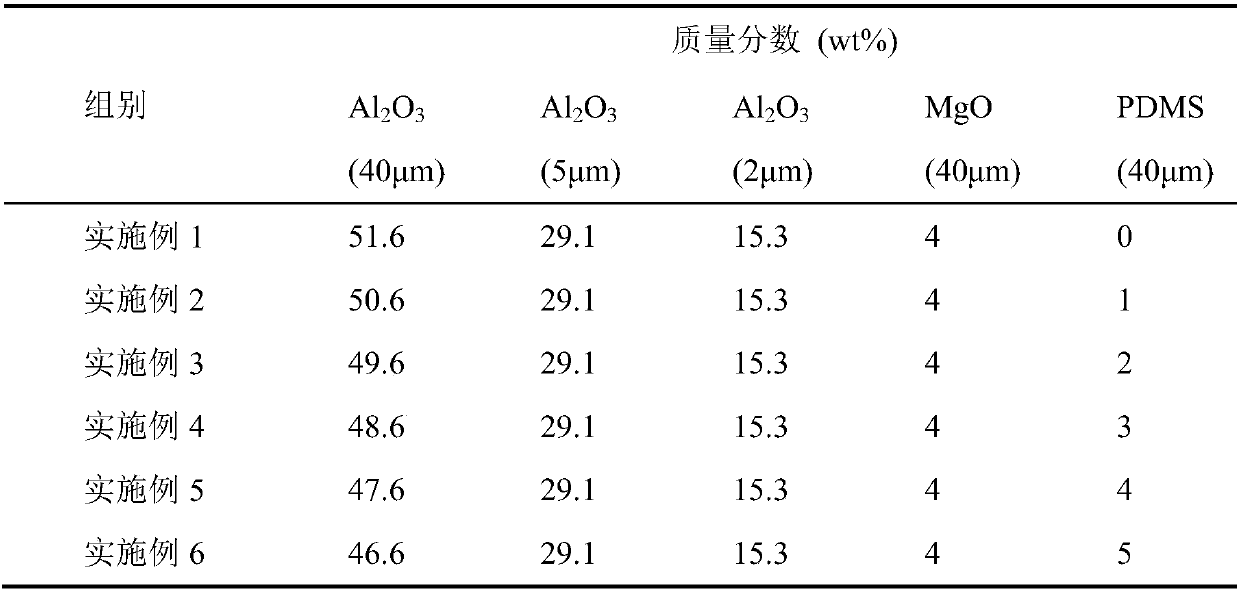

[0043] The composition of raw materials in Examples 1-6 is shown in Table 1.

[0044] Table 1 Composition of the ceramic body sample containing polydimethylsiloxane

[0045]

[0046] A standard sample was prepared by pouring a resin mold with a ceramic slurry with a solid content of 60vol%. After the sample was freeze-dried, refer to the HB 5353.3-2004 testing standard, and use a high-temperature stress-strain testing machine to measure the temperature of the sample from 200°C to 600°C. three-point flexural strength.

[0047] The bending strength of the sample body at 200-600°C during the deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com