Filter membrane assembly with one ends of membrane component and membrane filament being movable

A membrane element and membrane filament technology, which is applied in membrane technology, semi-permeable membrane separation, sustainable biological treatment, etc., can solve the mechanical damage of membrane filaments, easy accumulation of pollutants in membrane bundles, and affect the quality of membrane effluent. lifespan and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

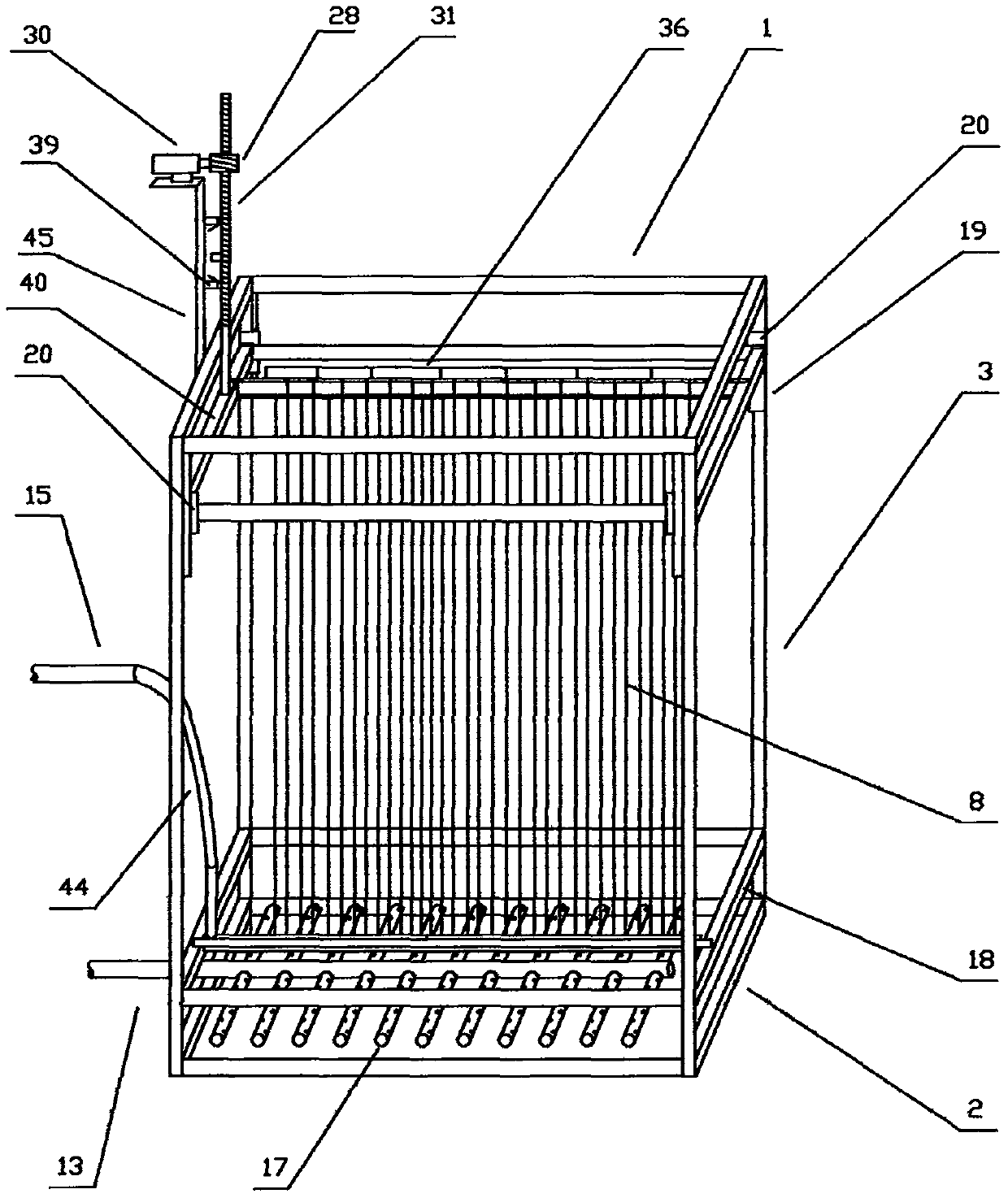

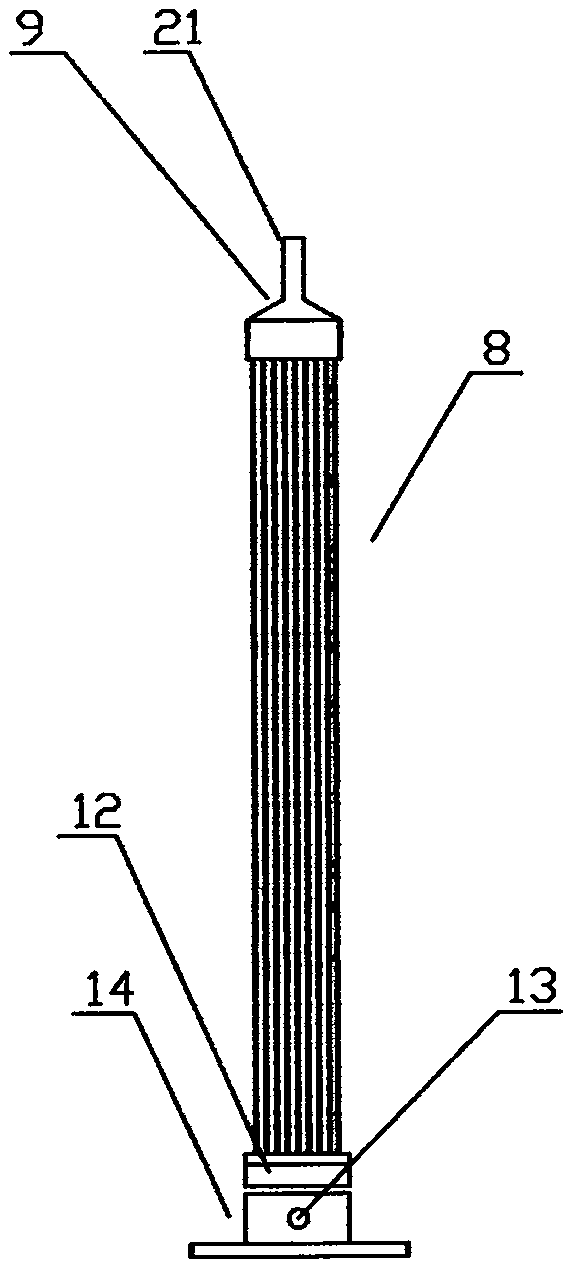

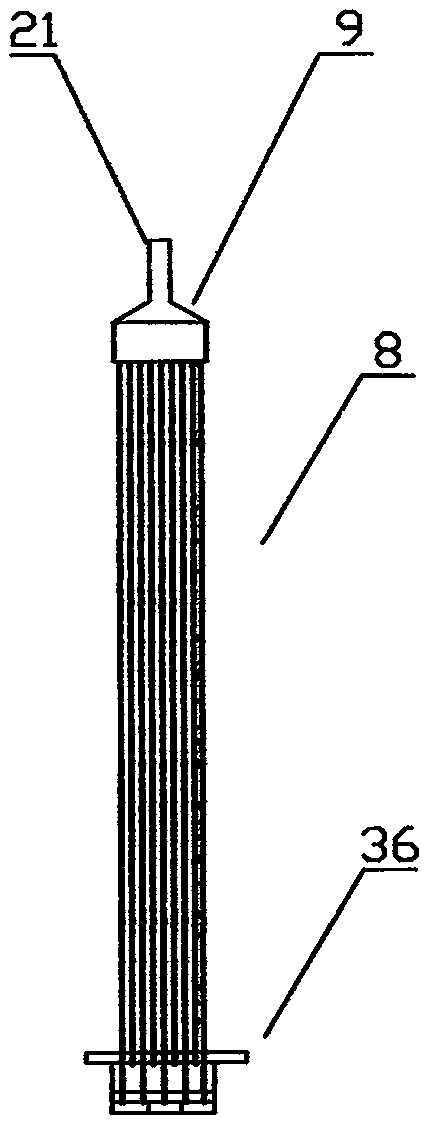

[0046] The structure and characteristics of the membrane element and the filter membrane assembly with a movable end of the membrane filament of the present invention will be described in detail below with reference to the accompanying drawings:

[0047] Membrane elements and membrane components with movable ends of membrane filaments, such as figure 1 Shown: Its structure includes membrane element, frame, membrane filament horizontal tube 36 or membrane filament vertical tube 35, fixed horizontal plate or fixed vertical plate, mobile system and aeration system; the frame is divided into a frame with a water retaining system and a non- There are two types of frames with water-retaining system. The frame without water-retaining system includes bottom plate 4, lower horizontal pipe 2, vertical pipe 3, upper horizontal pipe 1. The bottom plate 4 is square or rectangular, and is set in the lower part, four of the bottom plate 4 The corners are respectively fixedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com