Preparation method of paris root wall-broken decoction pieces used for treating welling-abscess swelling, tuberculosis and chronic cough, and paris root wall-broken decoction pieces prepared by method

A technology of broken wall decoction pieces and grass car, which is applied in the directions of medical preparations, pharmaceutical formulations, and plant raw materials containing active ingredients, can solve the problems of not being widely used, and no industry norms have been formed, and achieves good composition consistency, which is beneficial to The effect of modern large-scale industrialization development and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of Caoheche broken wall decoction pieces of the present invention comprises the following steps:

[0018] (a) pre-crushing the dried Herba Medicinae medicinal material to obtain medicinal material granules with a particle size of 10-100 mesh;

[0019] (b) immersing the granules of the medicinal material Caoheche with 30-60% by weight of ethanol aqueous solution;

[0020] (c) filter, freeze-dry the obtained filter cake, the temperature of freeze-drying is -10 ℃~-50 ℃, and the degree of vacuum is 5-50Pa;

[0021] (d) Place at a temperature of -10°C to 0°C for 1-3 hours;

[0022] (e) subjecting the obtained Caoheche particles to microwave treatment under vacuum conditions, and then performing ultrafine pulverization to obtain ultrafine powders below 40 microns;

[0023] (f) The ultrafine powder is mixed with a 60-80% by weight aqueous ethanol solution, followed by granulation and drying.

[0024] In the method of the present invention, after pre-g...

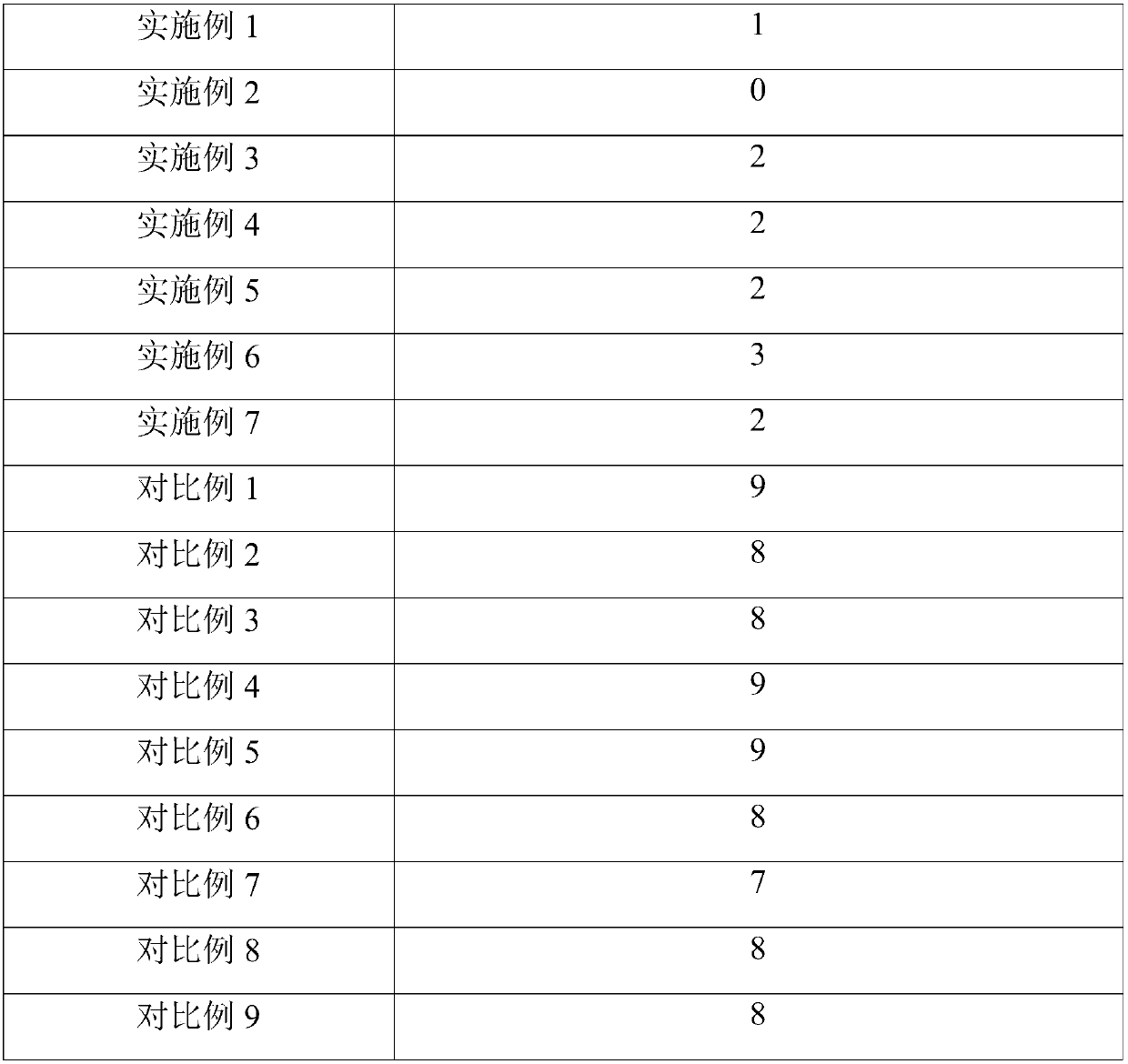

Embodiment 1

[0038] (1) Take 2.0kg of Caoheche medicinal material, pre-crushed to a particle size of 50 mesh particles, then add 45% by weight ethanol solution of 4 times the volume of Caoheche granules, soak for 2 hours at 70 ° C, and use 200 mesh stainless steel wire Filter through a mesh, and freeze-dry the obtained filter cake at -20°C under a vacuum of 30 Pa. After the Caoheche granules were dried, they were placed at -5°C for 2 hours.

[0039] (2) The Caoheche granules obtained in step (1) were placed under vacuum conditions for microwave treatment. The conditions of microwave treatment were as follows: the temperature was 25° C., the time was 30 minutes, the microwave power was 15 kW, and the vacuum degree was 15 Pa.

[0040] (3) Superfinely pulverize the Caoheche granules obtained in step (2) with a CW5-100QA wall-breaking superfine pulverizer to obtain ultrafine powder with a particle size of 5-30 microns.

[0041] (4) Mix the ultrafine powder with the ethanol aqueous solution wi...

Embodiment 2

[0043] (1) Take 2.0 kg of Caoheche medicinal material, pre-crushed to a particle size of 80 mesh particles, then add 60% by weight ethanol solution of 3 times the volume of Caoheche granules, soak for 3 hours at 50 ° C, and use 200 mesh stainless steel wire The obtained filter cake was lyophilized at -30° C. under a vacuum of 20 Pa. After the Caoheche granules were dried, they were placed at -8°C for 1 hour.

[0044](2) Place the Caoheche granules obtained in step (1) under vacuum conditions for microwave treatment. The microwave treatment conditions are as follows: the temperature is 20°C, the time is 40min, the microwave power is 10kW, and the vacuum degree is 10Pa.

[0045] (3) Superfinely pulverize the Caoheche granules obtained in step (2) with a CW5-100QA wall-breaking superfine pulverizer to obtain ultrafine powder with a particle size of 5-30 microns.

[0046] (4) Mix the ultrafine powder with the ethanol aqueous solution with a concentration of 60% by weight at a wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com