Hericium erinaceus wall-breaking decoction piece used for increasing immunity and preventing aging, and preparation method thereof

A technology of broken wall decoction pieces and monkey mushroom fungus, which is applied in the direction of medical raw materials derived from fungi, medical preparations containing active ingredients, antidote, etc. The effect of large-scale industrial development, good consistency of ingredients and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

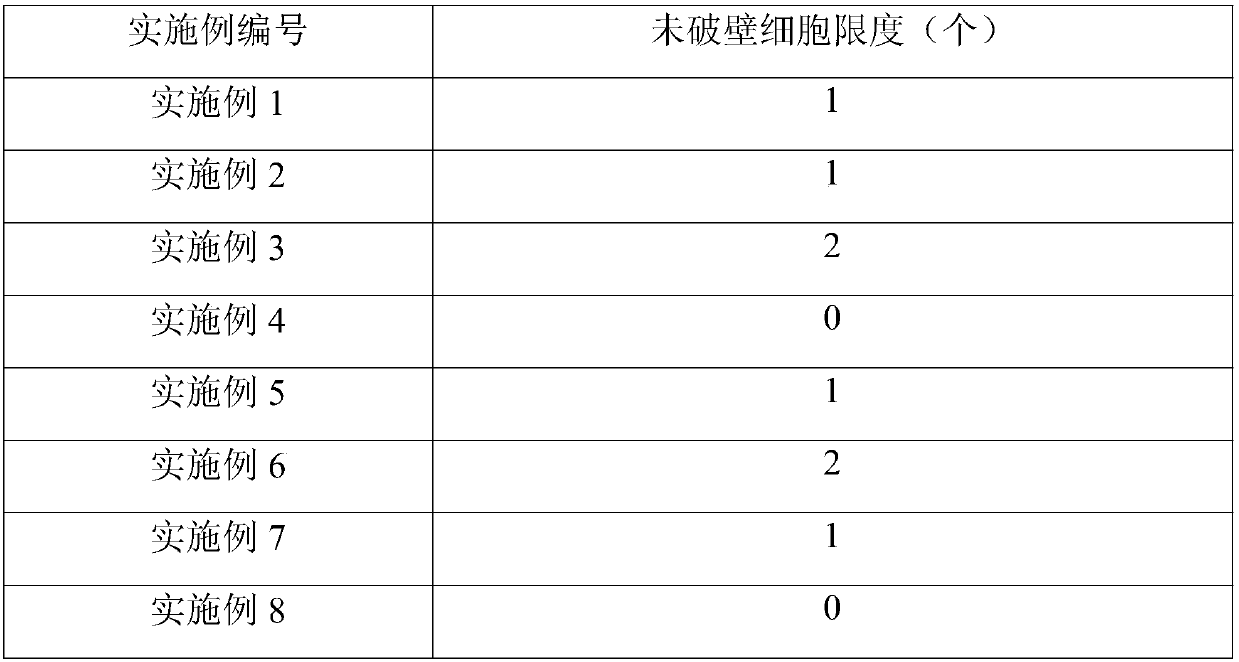

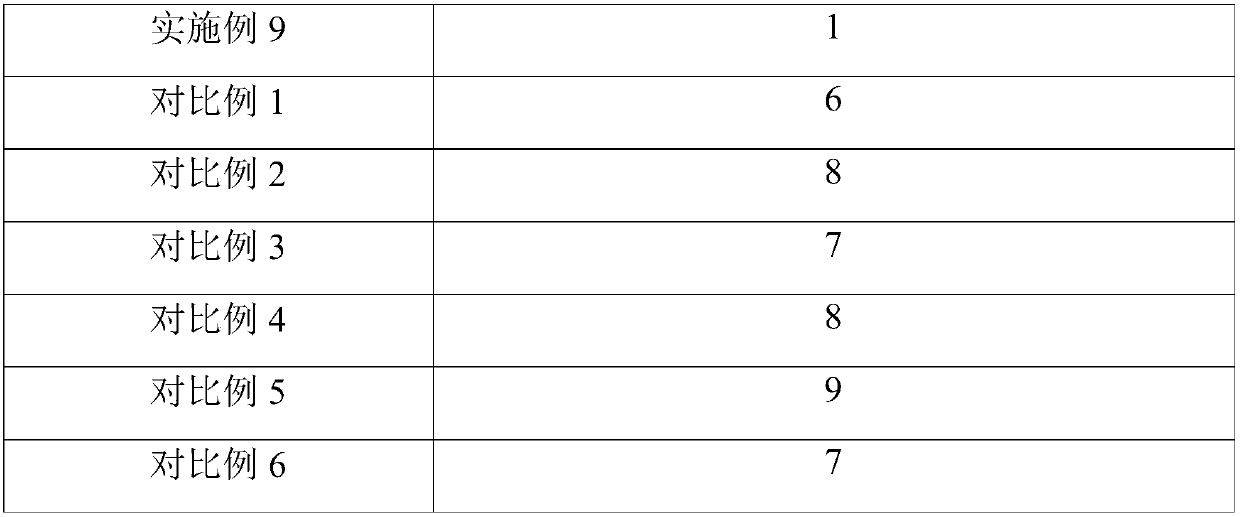

Examples

preparation example Construction

[0010] The preparation method of the broken-wall decoction pieces of Hericium erinaceus according to the present invention comprises: pre-crushing the dried Hericium erinaceus medicinal material into granules with a particle size of 40-100 mesh, adding the obtained Hericium mushroom medicinal material granules at a concentration of 30-40% by weight Soak in the ethanol aqueous solution, filter, the obtained filter cake is freeze-dried, the Hericium erinaceus granules obtained after the freeze-drying are subjected to microwave treatment under vacuum conditions, followed by ultrafine pulverization, and then the ultrafine powder obtained with a concentration of 50-60% by weight ethanol in water was mixed, then granulated and dried.

[0011] In the method of the present invention, the specific surface area of the Hericium erinaceus medicinal material is increased by pre-crushing the Hericium erinaceus medicinal material, which is more conducive to the subsequent soaking, freezing ...

Embodiment 1

[0024] Get 2.0kg of dry Hericium erinaceus medicinal materials, pre-crushed to a particle size of 80 mesh particles, then add 35% by weight ethanol solution of 4 times the volume of Hericium erinaceus particles, soak for 2 hours at 65 ° C, and use 200 mesh stainless steel wire mesh After filtration, the resulting filter cake was freeze-dried at -10°C under a vacuum of 30 Pa. The obtained Hericium erinaceus particles were placed under vacuum conditions for microwave treatment. The microwave treatment conditions were as follows: the temperature was 25° C., the time was 45 minutes, the microwave power was 15 kW, and the vacuum degree was 30 Pa. The obtained Hericium erinaceus granules are ultrafinely pulverized by a CW5-100QA wall-breaking ultrafine pulverizer to obtain ultrafine powder with a particle size of 5-30 microns. Mix the ultrafine powder with 55% by weight ethanol aqueous solution at a weight ratio of 1:0.7, extrude and granulate, and then freeze-dry at -10°C and 30Pa ...

Embodiment 2

[0026] Get 2.0kg of dry Hericium erinaceus medicinal materials, pre-crushed to a particle size of 40 mesh particles, then add 30% by weight ethanol solution of 5 times the volume of Hericium erinaceus particles, soak for 1 hour at 80 ° C, and use a 200 mesh stainless steel wire mesh After filtration, the resulting filter cake was freeze-dried at -10°C under a vacuum of 30 Pa. The obtained Hericium erinaceus particles were placed under vacuum conditions for microwave treatment. The microwave treatment conditions were as follows: the temperature was 25° C., the time was 45 minutes, the microwave power was 15 kW, and the vacuum degree was 30 Pa. The obtained Hericium erinaceus granules are ultrafinely pulverized by a CW5-100QA wall-breaking ultrafine pulverizer to obtain ultrafine powder with a particle size of 5-30 microns. Mix the ultrafine powder with 50% by weight ethanol aqueous solution at a weight ratio of 1:0.8, extrude and granulate, and then freeze-dry at -10°C and 30Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com