De-wheat bran barley aleurome layer compounded extruded rice and preparation method thereof

A technology of highland barley aleurone and highland barley powder, which is applied in the field of compound extruded rice with debraned highland barley aleurone layer and its preparation, can solve problems such as undiscovered, and achieve the effects of improving taste, facilitating large-scale production, and improving color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

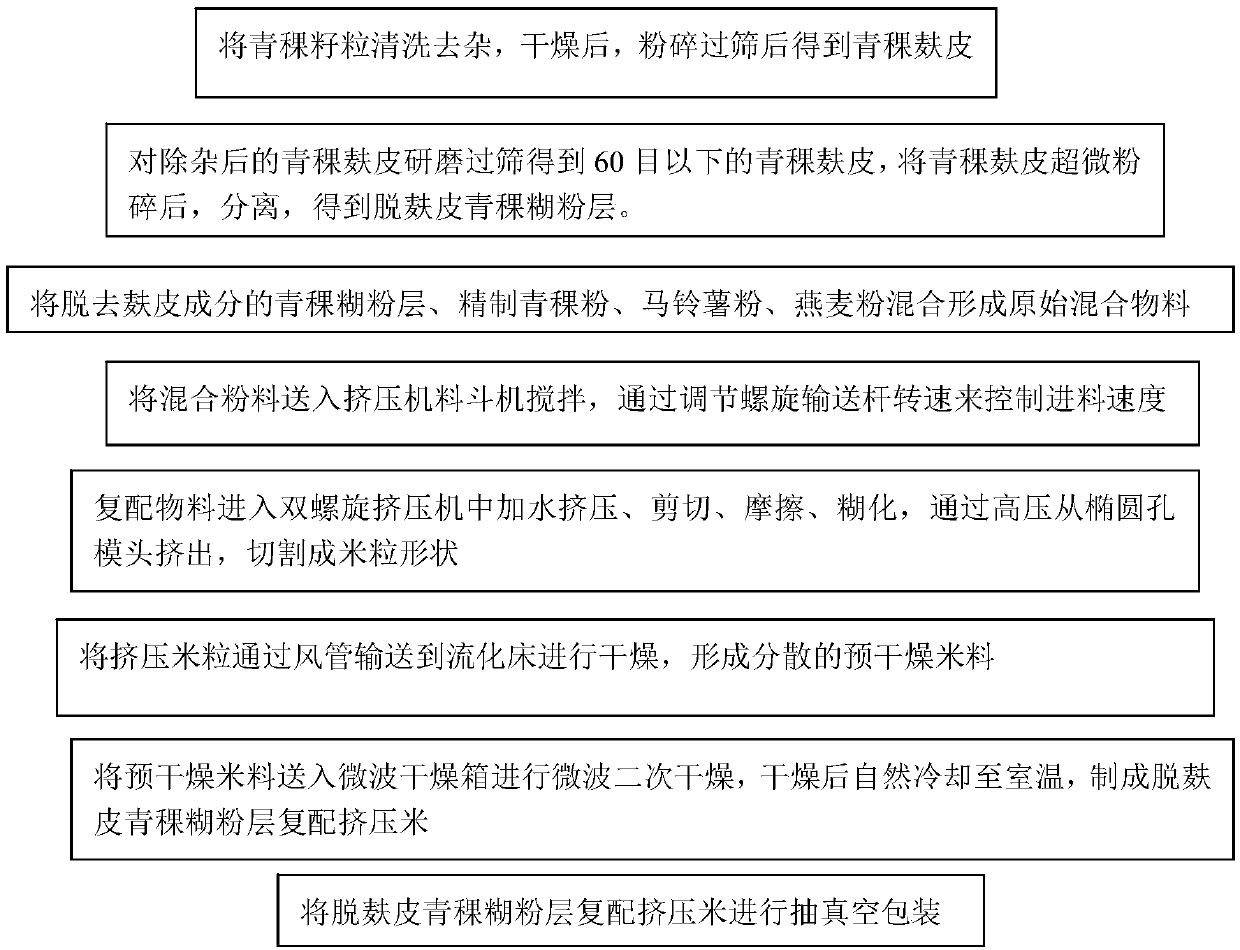

Method used

Image

Examples

Embodiment 1

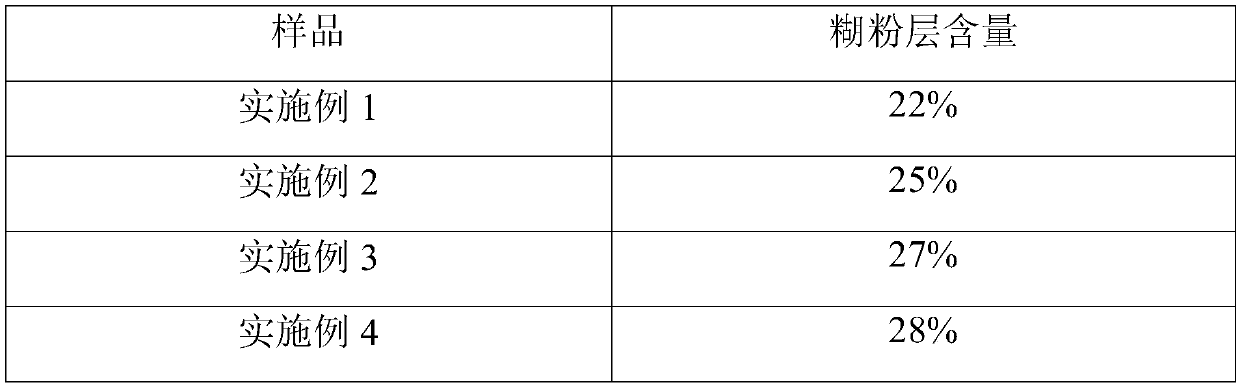

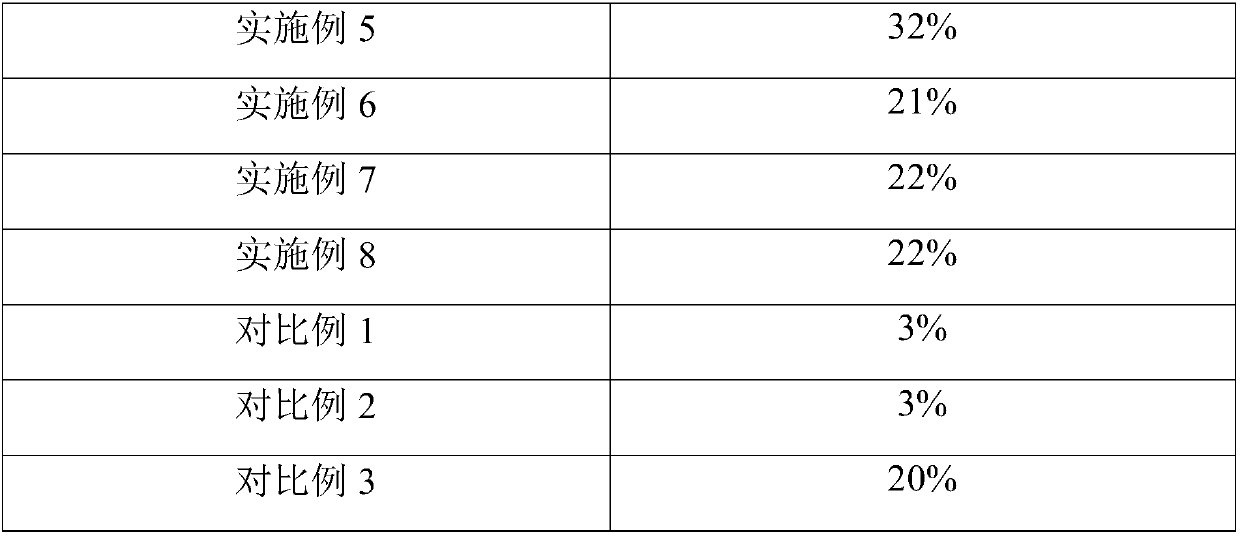

[0048] (1) Select highland barley grains with a β-glucan content of 4 to 8 wt%, wash, remove impurities, dry, grind and sieve to obtain highland barley bran that has not passed 60 mesh; after ultrafine grinding the highland barley bran, separate to obtain 100-300 μm aleurone layer of debraned highland barley.

[0049] (2) 20 parts by weight of the bran-free highland barley aleurone layer, 70 parts by weight of refined highland barley powder, 10 parts by weight of potato flour, and 5 parts by weight of oat flour are sent into the mixer for uniform mixing, and the material is continuously discharged from the lower outlet of the mixer, and then Pour into the upper inlet to keep the original powder uniform - so as to form a compound powder;

[0050] (3) Send the compound powder into the hopper of the twin-screw extruder, adopt the automatic mode, and set: the feed rate is 10kg / h, the water addition is 20%, T1 is 50°C, T2 is 65 ℃, T3 is 105°C, T4 is 115°C, T5 is 75°C and T6 is 45°...

Embodiment 2

[0053] (1) Select highland barley grains with a β-glucan content of 4 to 8 wt%, wash, remove impurities, dry, grind and sieve to obtain highland barley bran that has not passed 60 mesh; after ultrafine grinding the highland barley bran, separate to obtain 130-300 μm aleurone layer of debraned highland barley.

[0054] (2) 25 parts by weight of the bran-free highland barley aleurone layer, 70 parts by weight of refined highland barley flour, 10 parts by weight of potato flour, and 10 parts by weight of oat flour are sent into the mixer for uniform mixing, and the material is continuously discharged from the lower outlet of the mixer, Then pour it into the upper inlet to keep the original powder evenly - so as to form a compound powder;

[0055] (3) Send the compound powder into the hopper of the twin-screw extruder, adopt the automatic mode, and set: the feed rate is 15kg / h, the moisture addition is 21%, and the six temperature zones are set to T1 to 55 ℃, T2 is 70°C, T3 is 10...

Embodiment 3

[0058] (1) Select highland barley grains with a β-glucan content of 4 to 8 wt%, wash, remove impurities, dry, grind and sieve to obtain highland barley bran that has not passed 60 mesh; after ultrafine grinding the highland barley bran, separate to obtain 130-300 μm aleurone layer of debraned highland barley.

[0059] (2) 30 parts by weight of the bran-free highland barley aleurone layer, 65 parts by weight of refined highland barley flour, 15 parts by weight of potato flour, and 15 parts by weight of oat flour are sent into the mixer for uniform mixing, and are continuously discharged from the outlet of the mixer, Then pour it into the upper inlet to keep the original powder evenly - so as to form a compound powder;

[0060] (3) Send the compound powder into the hopper of the twin-screw extruder, adopt the automatic mode, and set: the feeding amount is 13kg / h, the water addition amount is 23%, T1 is 50°C, and T2 is 60°C °C, T3 is 105 °C, T4 is 115 °C, T5 is 70 °C and T6 is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com