Preparation method of pine needle-radix astragali particle

A technology of pine needles and pine needles, applied in the field of preparation of pine qi powder granules, which can solve problems such as short-term use, difficulties in actual use by farmers, and easy dampness of pine needle powder and astragalus powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

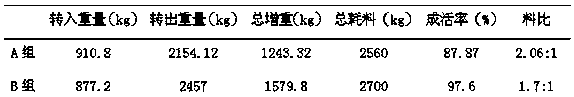

Examples

Embodiment 1

[0014] Crush 30kg of pine needles, pass through a 40-mesh sieve, and dry in a 70°C drying oven to about 25kg; then 50kg of astragalus is ultrafinely pulverized into a 200-mesh fine powder, and 75kg of pine needles powder and astragalus powder are mixed; add 600kg of Stir the water until it becomes thick, let stand for 1 hour, then heat and extract at a temperature of 100°C for 2 hours, then concentrate the extract to a relative density of 1.4±0.1 to obtain 100 kg of Songqi powder extract. Then add 80kg dextrin and 150kg starch, put it in the granulator and carry out bottom spray granulation, and carry out coating at the same time, the concentration of the coating agent is 5% acrylic resin solution. The process conditions are: 4 levels of air intake, 45°C inlet air temperature, 40°C outlet air temperature, 1.6bar atomization pressure, 1.0mm nozzle diameter, and 4ml / min spray speed.

Embodiment 2

[0016] Crush 50kg of pine needles, pass through a 40-mesh sieve, and dry in a 70°C drying oven to about 40kg; then ultrafinely pulverize 80kg of astragalus into 200-mesh fine powder, mix pine needles powder and astragalus powder into 120kg of pine needles powder; add 1000kg of Stir the water until it becomes thick, let it stand for 1 hour, then heat and extract at a temperature of 100°C for 2 hours, then concentrate the extract to a relative density of 1.4±0.1 to obtain 180 kg of Songqi powder extract. Then add 150kg dextrin and 220kg starch, put it in the granulator and carry out bottom spray granulation, and carry out coating at the same time. The coating agent is acrylic resin solution with a concentration of 5%. The process conditions are: 4 levels of air intake, 50°C inlet air temperature, 40°C outlet air temperature, 1.8bar atomization pressure, 1.0mm nozzle diameter, and 4ml / min spray speed.

Embodiment 3

[0018] Crush 60kg of pine needles, pass through a 40-mesh sieve, and dry in a 70°C drying oven to about 50kg; then superfinely grind 100kg of Astragalus membranaceus into a 200-mesh fine powder, mix pine needles powder and Astragalus membranaceus powder into 150kg of pine membranaceus powder; add 1200kg of Stir the water until it becomes thick, let it stand for 1 hour, then heat and extract at a temperature of 100°C for 2 hours, then concentrate the extract to a relative density of 1.4±0.1 to obtain 200 kg of Songqi powder extract. Then add 150kg dextrin and 250kg starch, put it in the granulator and carry out bottom spray granulation, and carry out coating at the same time, the concentration of the coating agent is 5% acrylic resin solution. The process conditions are as follows: 4 levels of air intake, 45°C inlet air temperature, 30°C outlet air temperature, 1.6bar atomization pressure, 1.0mm nozzle diameter, and 3ml / min spray speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com