Formula food for premature/low birth weight infants, and preparation method thereof

A low-birth-weight, infant formula technology, applied in the field of premature/low-birth-weight infant formula and its preparation, can solve the problems of scarcity of premature/low-birth-weight infant formula, inability to achieve breast milk, and low investment, etc. High digestible amino acid score, beneficial to digestion and absorption, and the effect of increasing fat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

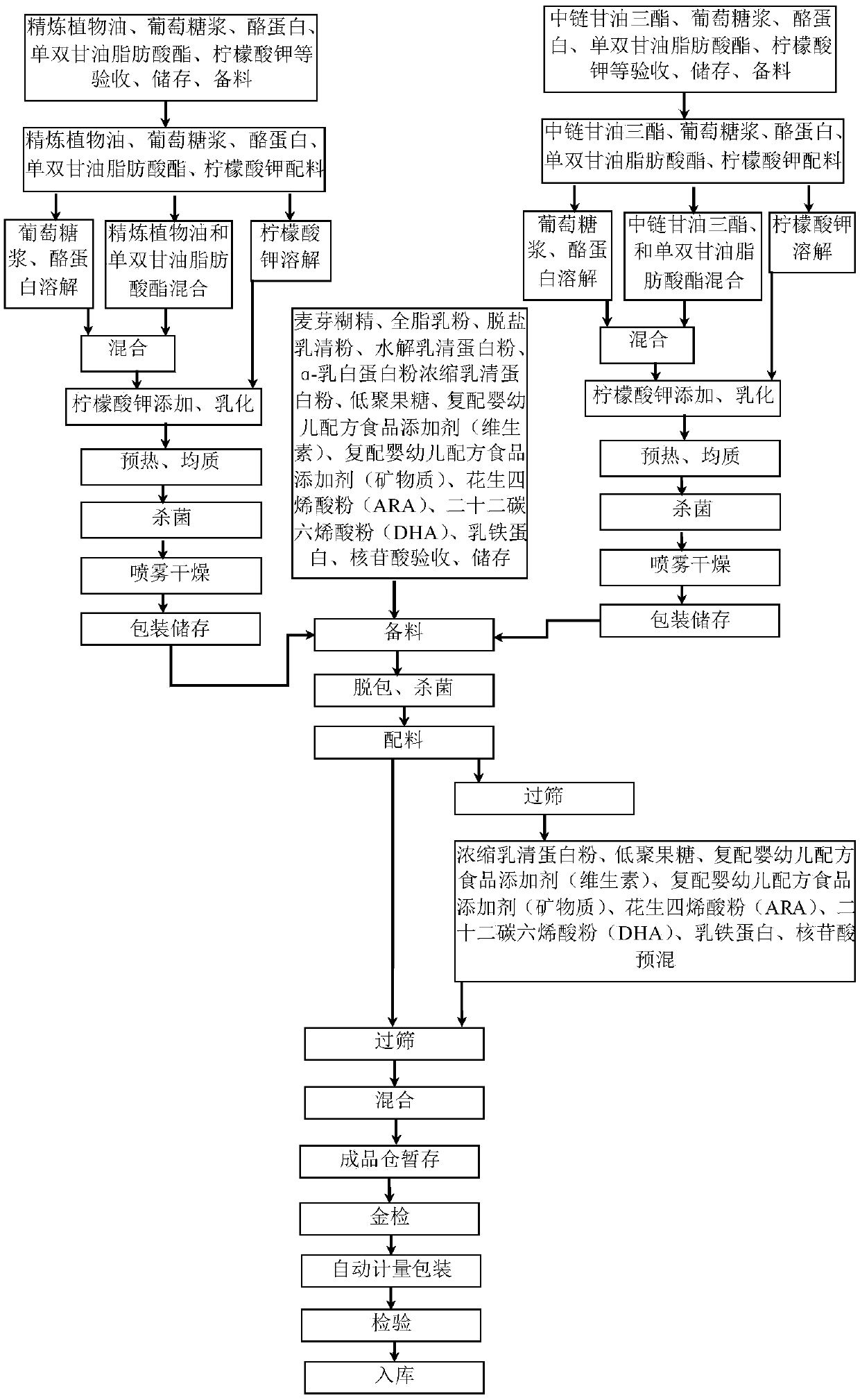

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of described vegetable fat powder is:

[0053] 1) mixing glucose syrup with water to obtain material liquid A;

[0054] 2) Mixing refined vegetable oil and mono-diglyceride fatty acid esters to obtain material liquid B;

[0055] 3) mixing sodium dihydrogen phosphate, potassium citrate, sodium citrate and water to obtain material liquid C;

[0056] 4) mixing feed liquid A and feed liquid B to obtain feed liquid D;

[0057] 5) Mixing the feed liquid C with the feed liquid D to obtain the feed liquid E;

[0058] 6) Carry out high-speed emulsification of the material liquid E, and then carry out homogenization, sterilization, spray drying and cooling in sequence to obtain vegetable fat powder.

[0059] Specifically, the glucose syrup and casein are dissolved in warm water at about 60±2°C to obtain feed liquid A. Wherein, the volume ratio of the glucose syrup to water is (1-1.1):2.

[0060] Mixing refined vegetable oil and mono-diglyceride fatty a...

Embodiment 1

[0144] 1. The formula of vegetable fat powder: 150 parts of refined vegetable oil (including: rapeseed oil (64.51 parts), corn oil (54.02 parts), coconut oil (31.51 parts)), 128 parts of glucose syrup, 18 parts of casein, 11 parts Mono-diglyceride fatty acid esters, 1.3 parts of sodium dihydrogen phosphate, 1.1 parts of sodium citrate, 0.6 parts of potassium citrate;

[0145] 2. Preparation method:

[0146] 1) Glucose syrup and casein dissolution: Dissolve glucose syrup and casein with warm water at about 60±2°C at a ratio of 1 to 1.1:2 (glucose syrup: purified water) to obtain feed solution A;

[0147] 2) Refined vegetable oil and mono-diglyceride fatty acid esters are mixed according to the formula ratio to obtain material liquid B;

[0148] 3) Dissolving sodium dihydrogen phosphate, potassium citrate, and sodium citrate: dissolving sodium dihydrogen phosphate, potassium citrate, sodium citrate and purified water at a ratio of 1:20 to obtain material liquid C;

[0149] 4) ...

Embodiment 2

[0156] 1. The formula of medium-chain triglyceride powder: 78 parts of medium-chain triglycerides, 28 parts of glucose syrup, 11 parts of casein, 0.9 parts of potassium citrate, and 2.1 parts of mono- and diglyceride fatty acid esters.

[0157] 2. Preparation method:

[0158] 1) Glucose syrup and casein dissolution: Dissolve glucose syrup and casein with warm water at about 60±2°C at a ratio of 1 to 1.1:2 (glucose syrup: purified water) to obtain feed solution A;

[0159] 2) Medium-chain triglycerides and mono-diglyceride fatty acid esters are mixed according to the formula ratio to obtain material liquid B;

[0160] 3) dissolving potassium citrate: dissolving potassium citrate and purified water at a ratio of 1:20 to obtain material liquid C;

[0161] 4) mixing feed liquid A and feed liquid B to obtain feed liquid D;

[0162] 5) Slowly add feed liquid C to feed liquid C while rapidly shearing and stirring to obtain feed liquid E;

[0163] 6) For liquid E, emulsify at high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com